Road carriageway porous pavement structure and pavement method thereof

A permeable pavement and traffic lane technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of no temporary water storage function, drainage pavement does not have characteristics, etc., to improve crack resistance, prevent structural damage, pavement The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

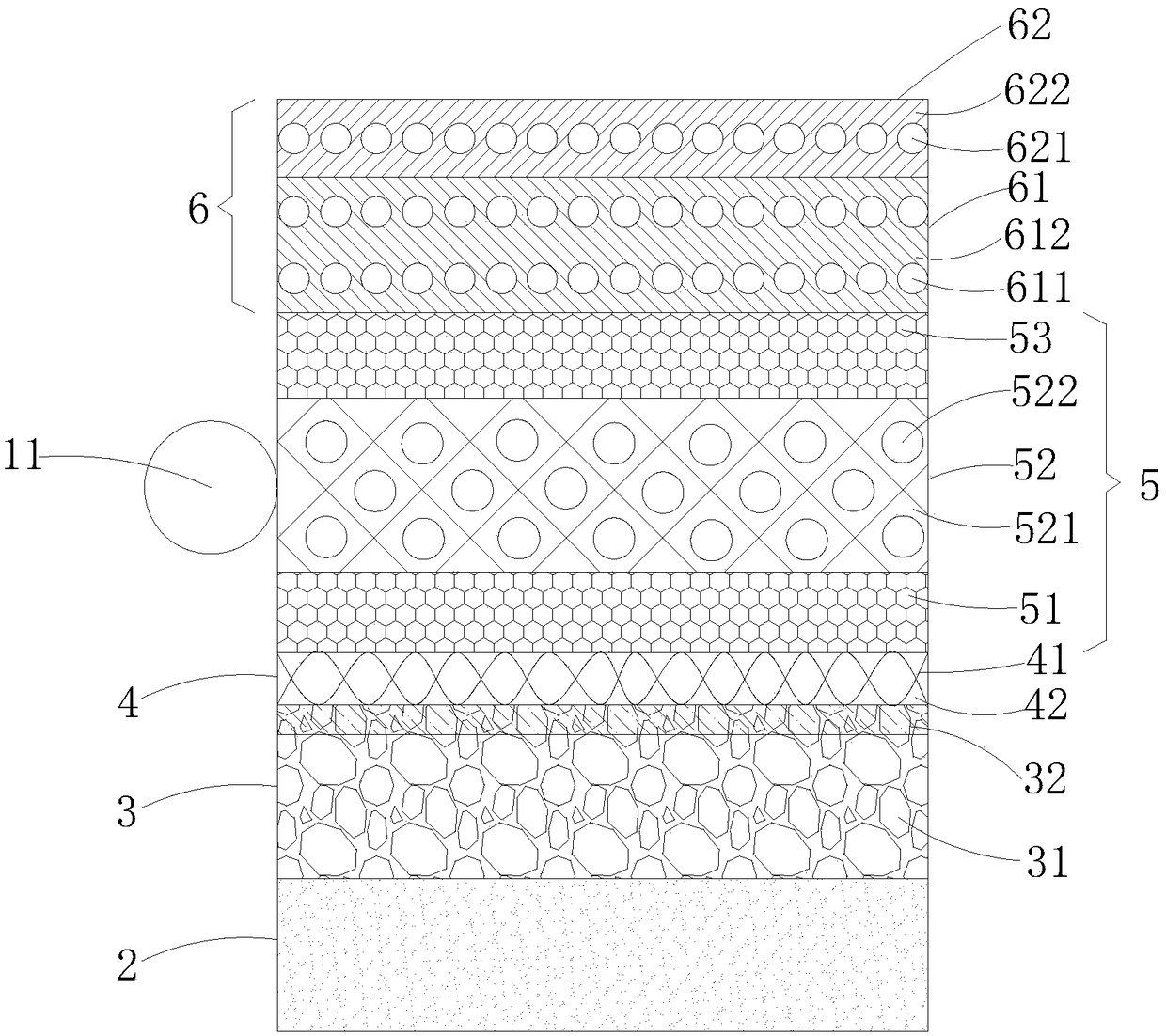

[0035] Such as figure 1 The shown roadway permeable pavement structure includes a strengthening layer 3, a water sealing layer 4, a base layer 5 and a surface layer 6 arranged on the soil foundation 2;

[0036] The reinforcement layer 3 includes a concrete layer 31 and a first waterproof layer 32 located on the top of the concrete layer 31; the first waterproof layer 32 is formed by curing emulsified asphalt. The thickness of the reinforcing layer 3 is 50 cm; the thickness of the first waterproof layer 32 is 3 mm.

[0037] The water sealing layer 4 includes a porous structure formed by interweaving rock fibers 41 and a second waterproof layer 42 filled in the pores of the porous structure; the thickness of the water sealing layer 4 is 1.5 cm; the porous structure The porosity is 35%. The second waterproof layer 42 is solidified by emulsified asphalt; the rock fibers 41 are basalt fibers.

[0038] The base layer 5 includes a lower base layer 51, a middle base layer 52 and an...

Embodiment 2

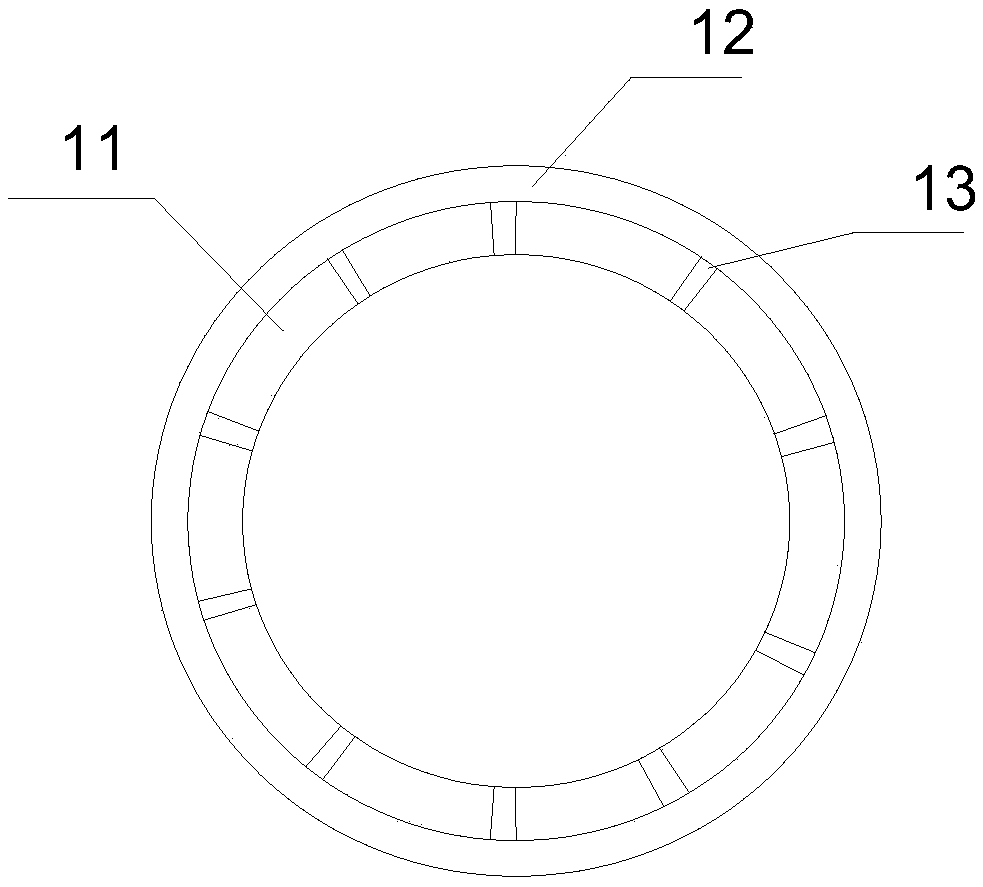

[0048] Compared with Embodiment 1, the difference of the roadway permeable pavement structure of this embodiment is: as figure 2 As shown, the drain pipe 11 is provided with a filter device, and the filter device includes a through hole 13 passing through the drain pipe 11 and a filter membrane 12 arranged on the outer surface of the drain pipe 11 .

Embodiment 3

[0050] Compared with Embodiment 1, the difference of the roadway permeable pavement structure of this embodiment is:

[0051] The first waterproof layer 32 is cured from polyurea. The thickness of the reinforcing layer 3 is 60 cm; the thickness of the first waterproof layer 32 is 4 mm.

[0052] The thickness of the water sealing layer 4 is 1 cm; the porosity of the porous structure is 20%. The second waterproof layer 42 is cured from polyurethane.

[0053] The particle size of the first crushed stone is 9.5 mm, the particle size of the second crushed stone 522 is 50 mm; the thickness of the lower base layer 51 and the upper base layer 53 is 10 cm; the thickness of the middle base layer 52 is 25 cm.

[0054] The thickness of the lower layer 61 is 6 cm; the thickness of the upper layer 62 is 6 cm; the maximum nominal particle size of the first gravel 611 is 25 mm; the maximum nominal particle size of the second gravel 621 is 14 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com