Paper deacidification agent composition and deacidification method for acidified paper

A technology of composition and deacidification agent, applied in the post-processing of waste paper, etc., can solve the problems of dangerous operation, reduced mechanical strength of paper, high cost, and achieve the effect of enhancing folding endurance and tensile strength, and prolonging paper life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

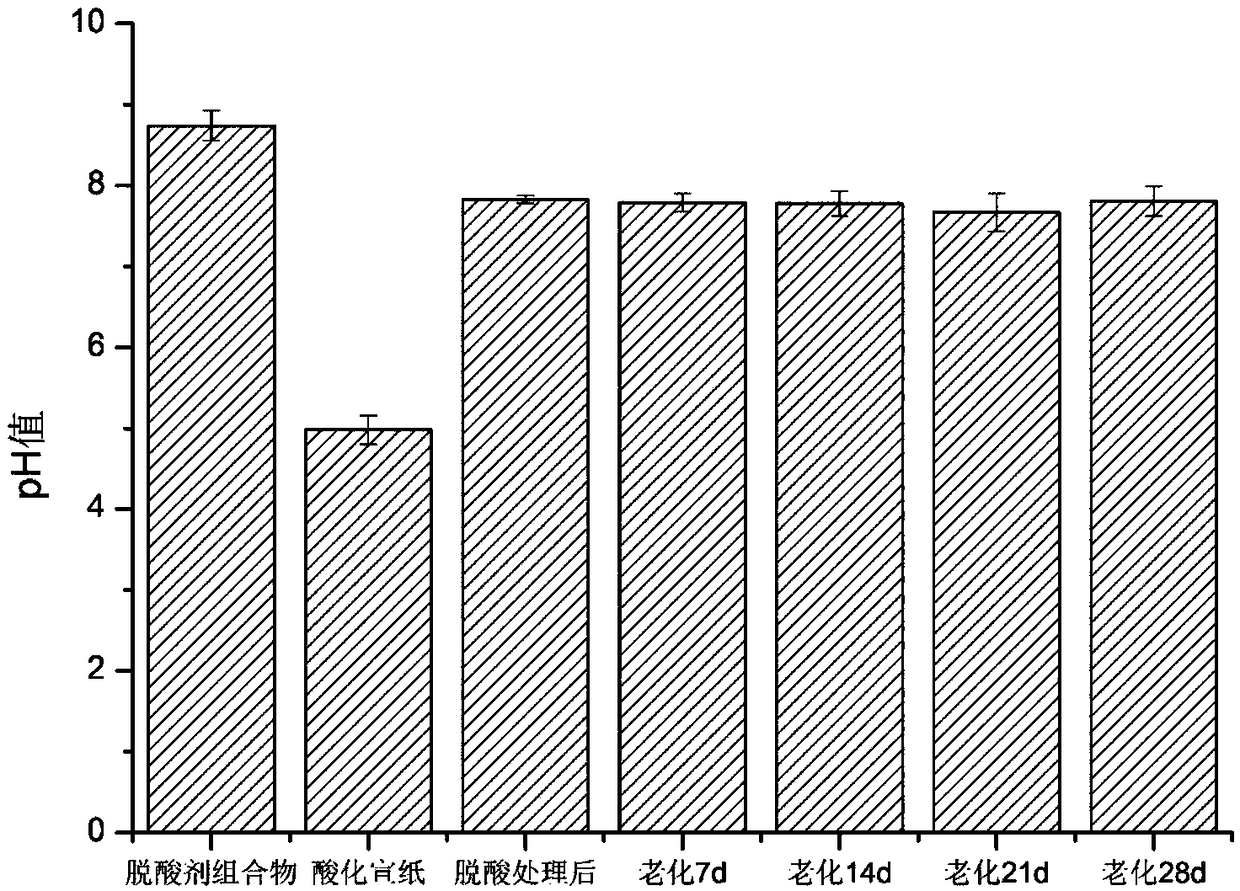

Embodiment 1

[0037] Mix 0.01 parts by weight of scopolamine, 0.02 parts by weight of scopolamine, 0.4 parts by weight of lithium tetraborate (with a particle size of 80 μm) and 99.57 parts by weight of ethanol aqueous solution (50% by volume of ethanol), fully stir and ultrasonically oscillate for 20 minutes, then let stand. Obtain the paper deacidifying agent composition of this embodiment, its pH value is 8.74.

Embodiment 2

[0039] Mix 0.009 parts by weight of scopolamine, 0.018 parts by weight of hyoscyamine, 0.5 parts by weight of lithium tetraborate (with a particle size of 100 μm) and 99.473 parts by weight of methanol aqueous solution (60% by volume of ethanol content), fully stir and ultrasonically oscillate for 20 minutes, then let stand. Obtain the paper deacidifying agent composition of this embodiment, its pH value is 8.63.

Embodiment 3

[0041] Mix 0.01 parts by weight of scopolamine, 0.01 parts by weight of scopolamine, 0.3 parts by weight of lithium tetraborate (with a particle size of 90 μm) and 99.68 parts by weight of n-butanol aqueous solution (50% by volume of n-butanol), fully stir and ultrasonically vibrate for 20 minutes After standing still, the paper deacidifier composition of this embodiment was obtained, and its pH value was 8.45.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com