Laser repair method of high-carbon hard-face crack-free large-thickness cold roll

A technology of laser repair and cold roll, which is applied in the field of rolls, can solve the problems such as the difficulty of crack control in the cladding layer, and achieve the effects of uniform and dense coating microstructure, improved efficiency, and reasonable process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

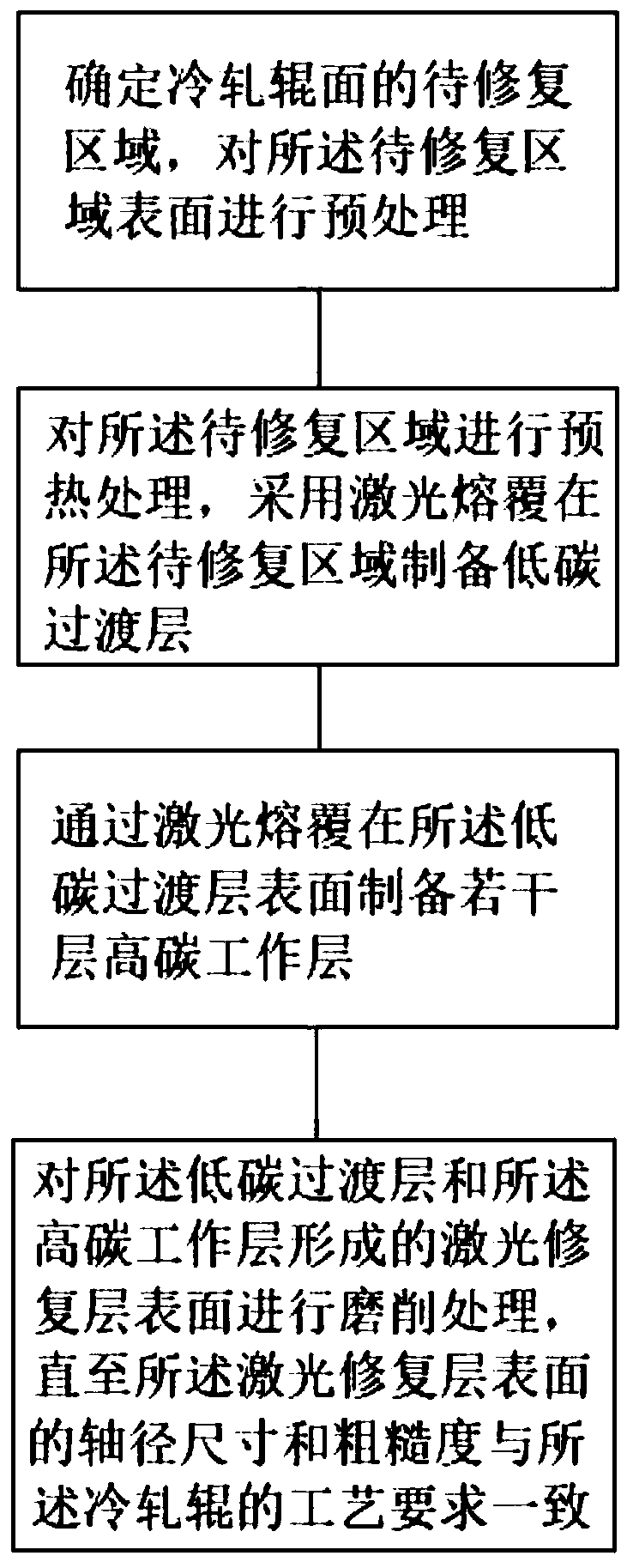

[0029] like figure 1 as shown, figure 1 It is a flow chart of the laser repair method for high-carbon hard-faced, crack-free, and large-thickness cold rolls of the present invention; the cold rolls in this embodiment adopt GCr15 cold rolls, and the GCr15 cold rolls are repaired by the repair method of the present invention The preparation of the laser repair layer including the low-carbon transition layer, the first working layer and the second working layer three-layer structure; specifically includes the following steps;

[0030] S1, determine the area to be repaired on the surface of the failed GCr15 cold roll, the area to be repaired is mainly a wear area and a peeling area, and distinguish the identified marks of the area to be repaired; the wear area and the peeling area Grinding the surface, performing colored penetrant inspection on the smooth surface after grinding, and stopping the grinding of the area to be repaired after confirming that the smooth surface after gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com