Mesomorphic substance internal cold shock gasification furnace

A gasifier and material technology, which is used in the gasification of granular/powdered fuel, the manufacture of combustible gas, the petroleum industry, etc., can solve the blockage of large slag, produce some solid-phase, liquid-phase carbonaceous substances and dioxins, Landfill leachate, heavy metals, technical difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

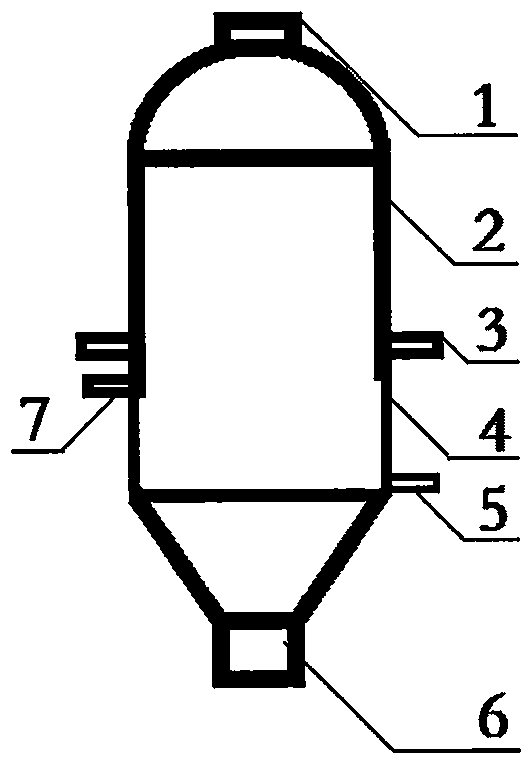

[0008] The combustible gas from the raw material pretreatment device enters the gasification chamber 2 through the multi-phase material channel of the nozzle 3, and is mixed with the gasification agent from the gasification agent channel of the nozzle 3 in the gasification chamber 2 and is ignited by the automatic ignition device Or artificially ignite and burn, heat up the gasification chamber, gradually increase the temperature of the gasification chamber to the normal operating temperature, and then add other gas phase substances, solid phase substances, liquid phase substances or solid phase, liquid phase substances into the combustible gas, after The multi-phase material channel of the nozzle 3 enters the gasification chamber 2 and the gasification agent passing through the gasification agent channel of the nozzle 3 is mixed together in the gasification chamber 2 for high-temperature thermochemical reaction, and the liquid phase material can also pass through the liquid pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com