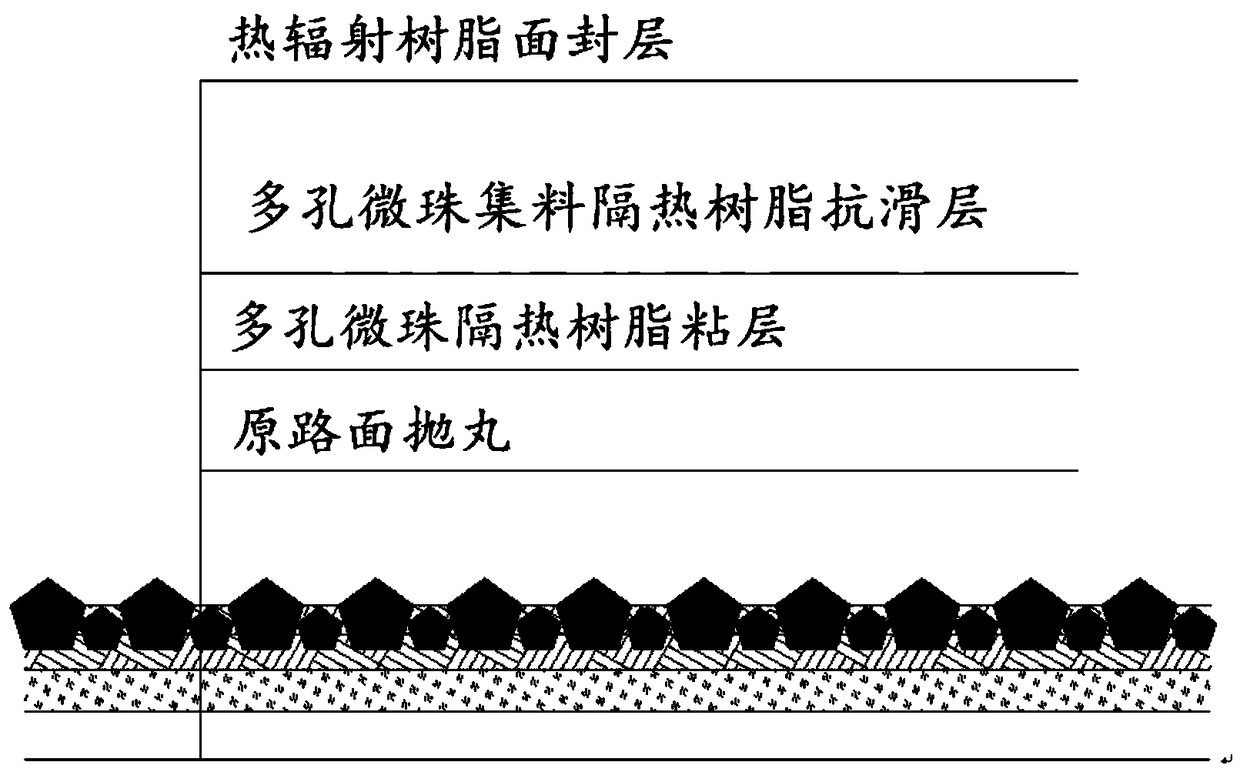

Multilayer composite thermal insulation covering and preparation method thereof

A composite and overlay technology, which is applied in the direction of film/sheet adhesive, on-site coagulation pavement, construction, etc., can solve the problem of poor applicability of existing pavement, affecting road surface structure texture, use Poor durability and other problems, to achieve the effect of ice-breaking and anti-freeze performance, improve the structure of the road surface, and improve the anti-rutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Calculated according to the number of parts by mass:

[0040] Step 1. Use a dust-free shot blasting machine to clean the epoxy asphalt pavement surface of the steel bridge deck to form a clean, dry base surface with a certain texture;

[0041] Step 2. Prepare high-viscosity resin and porous glass microspheres in a ratio of 5:1, and use high-speed shear mixing equipment to fully mix at a stirring rate of 800 / min for 1 minute, and then scrape and apply it on a clean and dry pavement Surface, the coating amount is 2.4kg / m 2 , after curing and forming strength, proceed to the next process of construction;

[0042] Among them, 260 parts of high-viscosity resin material and 52 parts of porous glass microspheres. The high-viscosity resin is made by reacting 200 parts of bisphenol A type and 60 parts of polyamide; the particle size of porous glass microbeads is 1-10 μm, and the pore size is 10 nm;

[0043] Step 3. Prepare high-toughness resin and porous glass microspheres in...

Embodiment 2

[0048] Calculated according to the number of parts by mass:

[0049] Step 1. Use a dust-free shot blasting machine to perform shot blasting on the surface of the asphalt pavement to form a clean, dry rough surface;

[0050] Step 2. Prepare high-viscosity resin and porous glass microspheres in a ratio of 5:1, and use high-speed shear mixing equipment to fully mix at a stirring rate of 800 / min for 2 minutes, and then scrape and apply it on a clean and dry pavement Surface, coating amount is 3.0kg / m 2 , after curing and forming strength, proceed to the next process of construction;

[0051] Among them, 325 parts of high-viscosity resin material, 65 parts of porous glass beads; high-viscosity resin is prepared by reacting 250 parts of bisphenol F type and 75 parts of modified amine 593; 10nm;

[0052] Step 3. Prepare high-toughness resin and porous glass microspheres in a ratio of 10:1, and use high-speed shear mixing equipment to fully mix at a stirring rate of 800r / min for 2 ...

Embodiment 3

[0057] Calculated according to the number of parts by mass:

[0058] Step 1. Use a dust-free shot blasting machine to perform shot blasting on the surface of the asphalt pavement to form a clean, dry rough surface;

[0059] Step 2. Prepare high-viscosity resin and porous glass microspheres in a ratio of 5:1, and use high-speed shear mixing equipment to fully mix at a stirring rate of 800 / min for 2 minutes, and then scrape and apply it on a clean and dry pavement Surface, coating amount is 3.0kg / m 2 , after curing and forming strength, proceed to the next process of construction;

[0060] Among them, there are 293 parts of high-viscosity resin materials and 59 parts of porous glass beads; the high-viscosity resin is prepared by reacting 225 parts of bisphenol A type and 68 parts of modified amine 593; the particle size of porous glass micro-beads is 1-10 μm, and the pore size is 10nm;

[0061] Step 3. Prepare high-toughness resin and porous glass microspheres in a ratio of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com