Anti-corrosion thermosetting powder coating

A thermosetting powder, corrosion-resistant technology, used in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as unfavorable fluorocarbon coatings popularization and application, poor compatibility of fluorocarbon resins, and large amount of fluorocarbon resins. Achieve the effect of improving spraying processing efficiency, improving poor wettability and reducing dosage

Inactive Publication Date: 2019-02-22

宁波爱甬新材料科技有限公司

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if the fluorocarbon resin is directly mixed with other resins, the compatibility of the fluorocarbon resin and other resins in the obtained thermosetting powder coating is not good, resulting in poor stability of the coating; and the amount of fluorocarbon resin in this coating is large, The cost is still high, which is not conducive to the promotion and application of fluorocarbon coatings

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

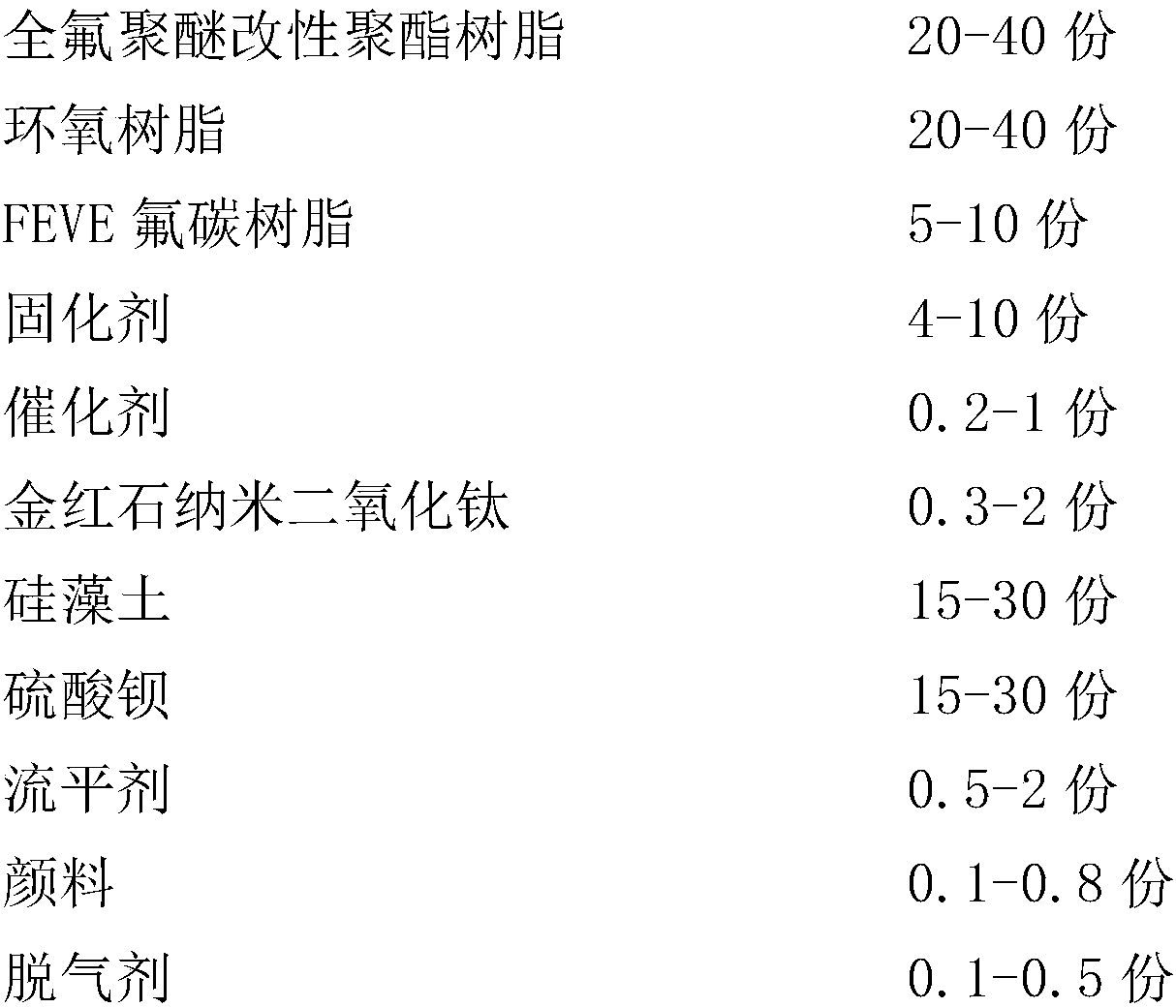

[0034] A kind of corrosion-resistant thermosetting powder coating, it comprises following raw material by weight:

[0035]

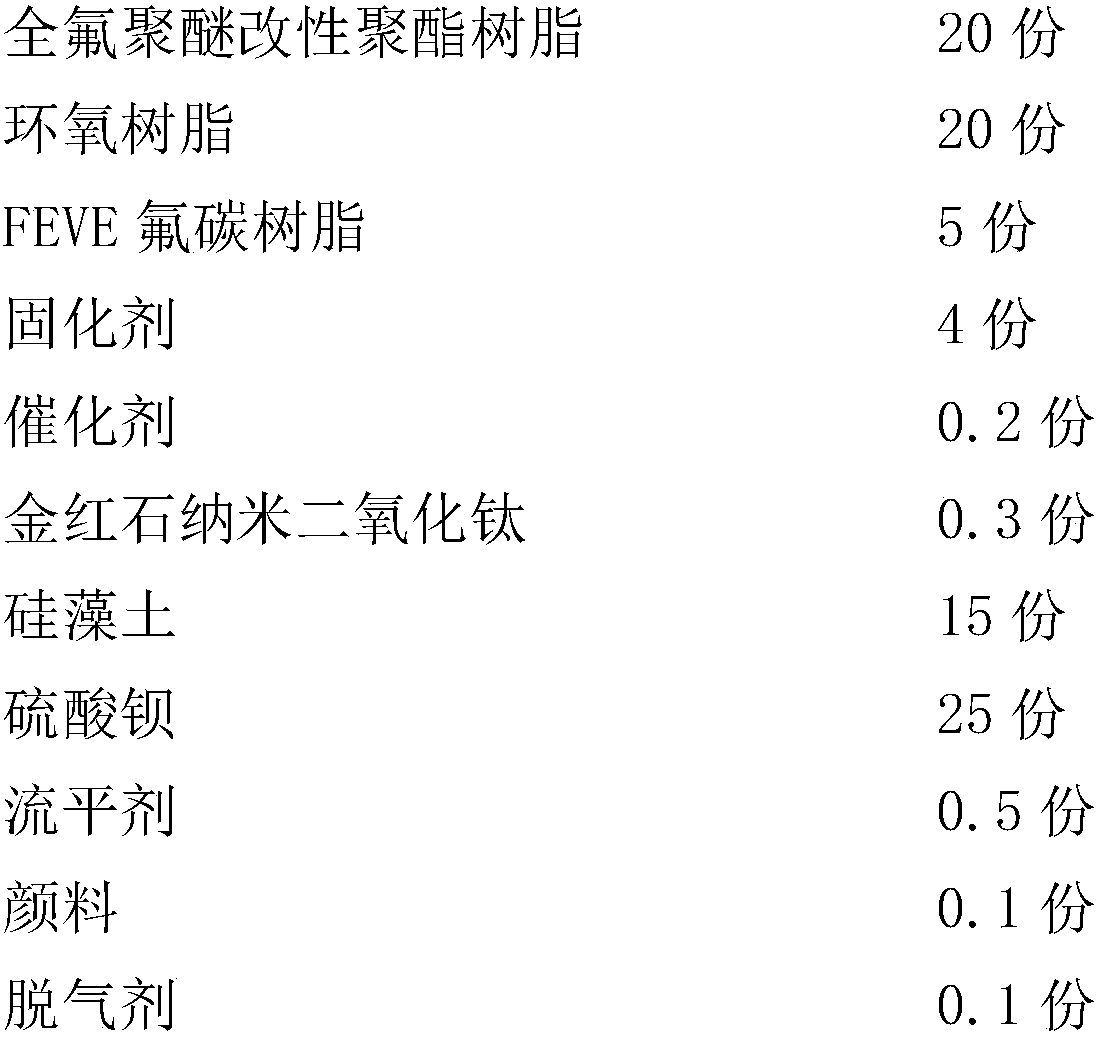

Embodiment 2

[0037] A kind of corrosion-resistant thermosetting powder coating, it comprises following raw material by weight:

[0038]

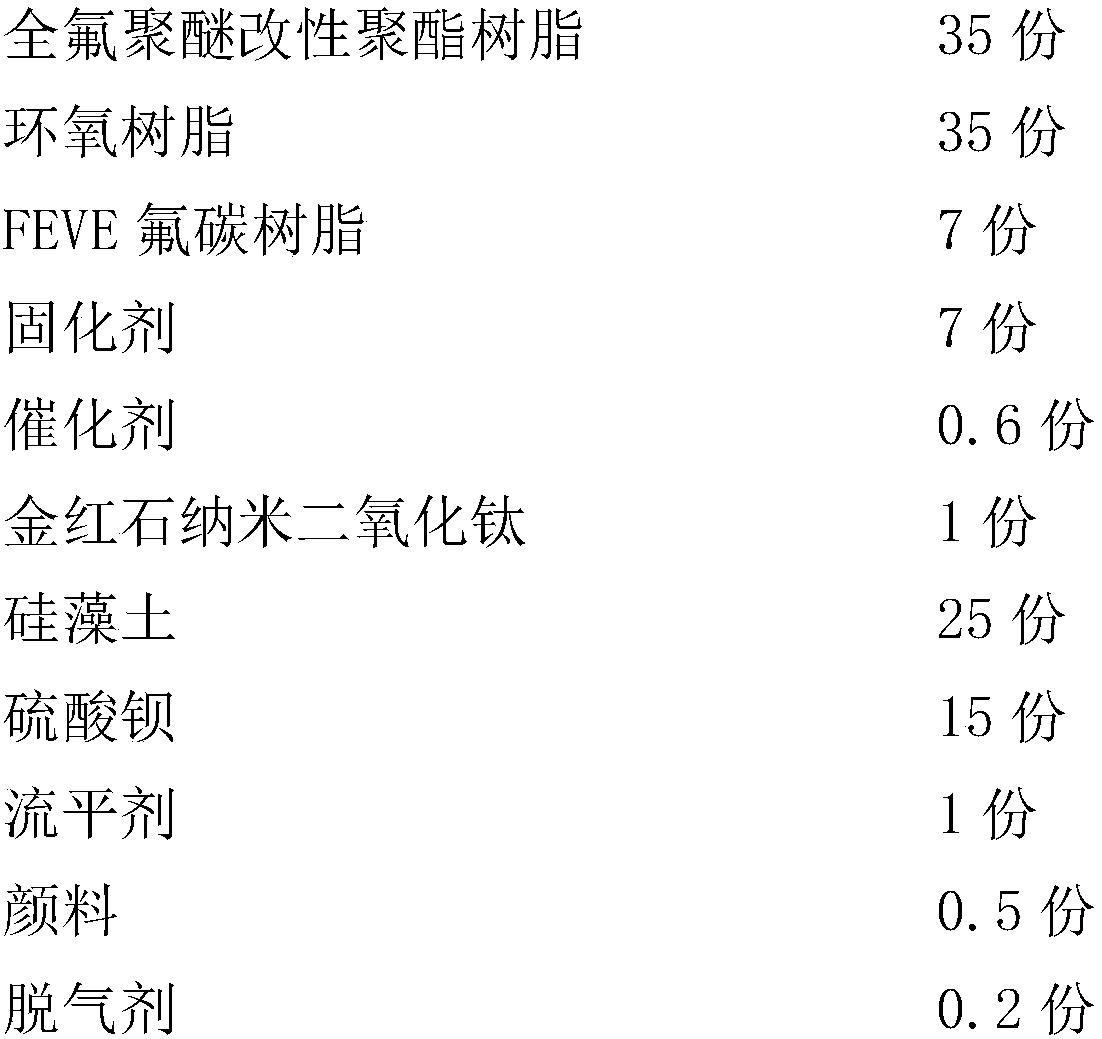

Embodiment 3

[0040]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an anti-corrosion thermosetting powder coating. The anti-corrosion thermosetting powder coating is composed of raw materials including, by weight part, 20-40 parts of perfluoroalkylpolyether modified polyester resin, 20-40 parts of epoxy resin, 5-10 parts of FEVE (fluoroethylene vinyl ether) fluorocarbon resin, 4-10 parts of curing agent, 0.2-1 part of catalyst, 0.3-2 parts of rutile nano-titanium dioxide, 15-30 parts of kieselguhr, 15-30 parts of barium sulfate, 0.5-2 parts of leveling agent, 0.1-0.8 part of pigment and 0.1-0.5 part of degassing agent. The anti-corrosion thermosetting powder coating compounds the perfluoroalkylpolyether modified polyester resin, the epoxy resin and the FEVE fluorocarbon resin to achieve high corrosion resistance, high adhesive force and good wettability.

Description

technical field [0001] The invention belongs to the field of thermosetting powder coatings, in particular, the invention relates to a corrosion-resistant thermosetting powder coating. Background technique [0002] Thermosetting powder coatings have become the "4E type" (high production efficiency, excellent coating performance, Eco-friendly, economical) coatings. At present, it is mainly used in metal coating, household appliances, automobiles, aluminum materials and other fields. According to statistics, the consumption of thermosetting powder coatings in my country was 1.05 million tons in 2012, 1.12 million tons in 2013, 1.24 million tons in 2014, 1.35 million tons in 2015, and 1.42 million tons in 2016. The annual sales volume reaches 1.605 million tons, showing an increasing trend year by year. Thermosetting powder coatings mainly include epoxy resin powder coatings, polyester powder coatings, polyurethane powder coatings, acrylic powder coatings, fluorocarbon powder ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D167/00C09D163/00C09D127/12C09D5/08C09D5/03C09D7/61

CPCC09D167/00C08K2003/2241C08K2003/3045C08L2201/08C08L2205/03C09D5/033C09D5/08C09D163/00C08L63/00C08L27/12C08K3/22C08K7/26C08K3/30C08K13/04C08L67/00

Inventor 夏行

Owner 宁波爱甬新材料科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com