A kind of antistatic polyester alloy material and preparation method thereof

A polyester alloy and antistatic technology, which is applied in the field of antistatic polyester alloy materials and its preparation, can solve the problems of reducing the amount of conductive carbon black, etc., and achieve the goal of reducing the amount of addition, ensuring stability, and uniform and stable surface resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

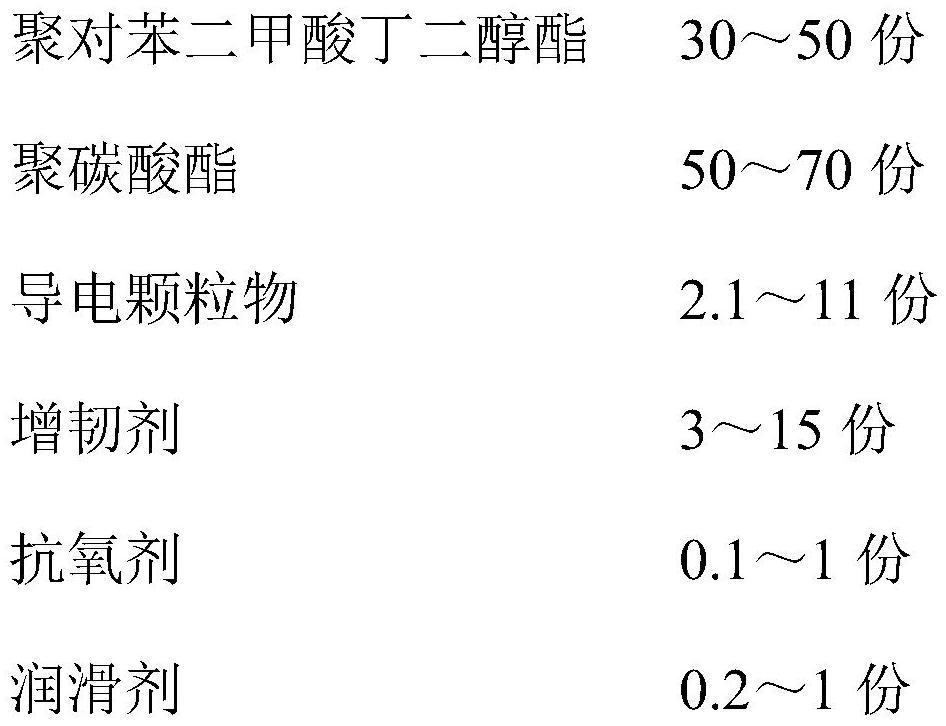

Method used

Image

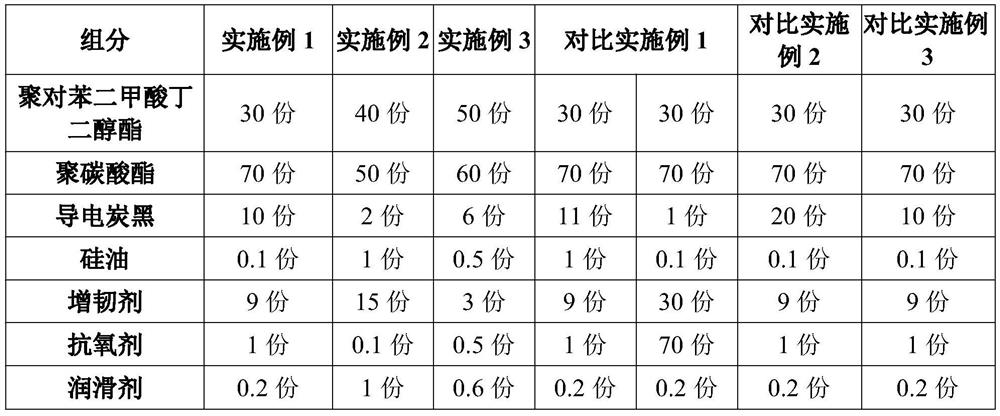

Examples

Embodiment 1

[0028]Example 1-A method for preparing an antistatic polyester alloy material, including the following steps:

[0029](1) Prepare conductive particles, mix conductive carbon black and silicone oil for 20 minutes to obtain granular conductive particles; the conductive carbon black has a chain structure with an average particle size of 150nm; the silicone oil has a density of 0.96 Methyl silicone oil;

[0030](2) Add polybutylene terephthalate, polycarbonate, conductive particles, toughening agent, antioxidant, and lubricant to a high-speed mixer and mix to obtain a mixed composition; wherein, the polymer is The viscosity of butylene phthalate is 0.45dl / gr; the weight average molecular weight of the polycarbonate is 25000; the toughening agent is MBS resin with a particle diameter of 300nm; the lubricant is silicone powder;

[0031](3) The mixed composition of step (2) is fed into the twin-screw extruder from the feed port, and a telescopic steel ball with a diameter of 30 cm is set at the mai...

Embodiment 2

[0032]Example 2-A preparation method of an antistatic polyester alloy material, including the following steps:

[0033](1) Prepare conductive particles, mix conductive carbon black and silicone oil for 30 minutes to obtain granular conductive particles; the conductive carbon black has a chain structure with an average particle size of 150nm; the silicone oil has a density of 0.96 Methyl silicone oil;

[0034](2) Add polybutylene terephthalate, polycarbonate, conductive particles, toughening agent, antioxidant, and lubricant to a high-speed mixer and mix to obtain a mixed composition; wherein, the polymer is The viscosity of butylene phthalate is 1.2 dl / gr; the weight average molecular weight of the polycarbonate is 40,000; the toughening agent is an MBS resin with a particle size of 600 nm; the lubricant is pentaerythritol ester;

[0035](3) Feed the mixed composition of step (2) into a twin-screw extruder, and use a telescopic steel ball with a diameter of 30cm set at the main discharge por...

Embodiment 3

[0036]Example 3-A method for preparing an antistatic polyester alloy material, including the following steps:

[0037](1) Prepare conductive particles, mix conductive carbon black and silicone oil for 25 minutes to obtain granular conductive particles; the conductive carbon black has a chain structure with an average particle size of 150nm; the silicone oil has a density of 0.96 Methyl silicone oil;

[0038](2) Add polybutylene terephthalate, polycarbonate, conductive particles, toughening agent, antioxidant, and lubricant to a high-speed mixer and mix to obtain a mixed composition; wherein, the polymer is The viscosity of butylene phthalate is 0.85dl / gr; the weight average molecular weight of the polycarbonate is 35000; the toughening agent is MBS resin with a particle size of 500nm; the lubricant is ethylene double hard Ester amide

[0039](3) Feed the mixed composition of step (2) into a twin-screw extruder, and use a telescopic steel ball with a diameter of 30cm set at the main discharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com