Orange peel-like rubber roller material and method for making orange peel-like rubber roller by utilizing material

A production method and technology of rubber rollers, which are applied in the field of rubber rollers, can solve the problems of relative sliding of thin steel plates, and achieve the effects of excellent permanent deformation rate, low deformation rate and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

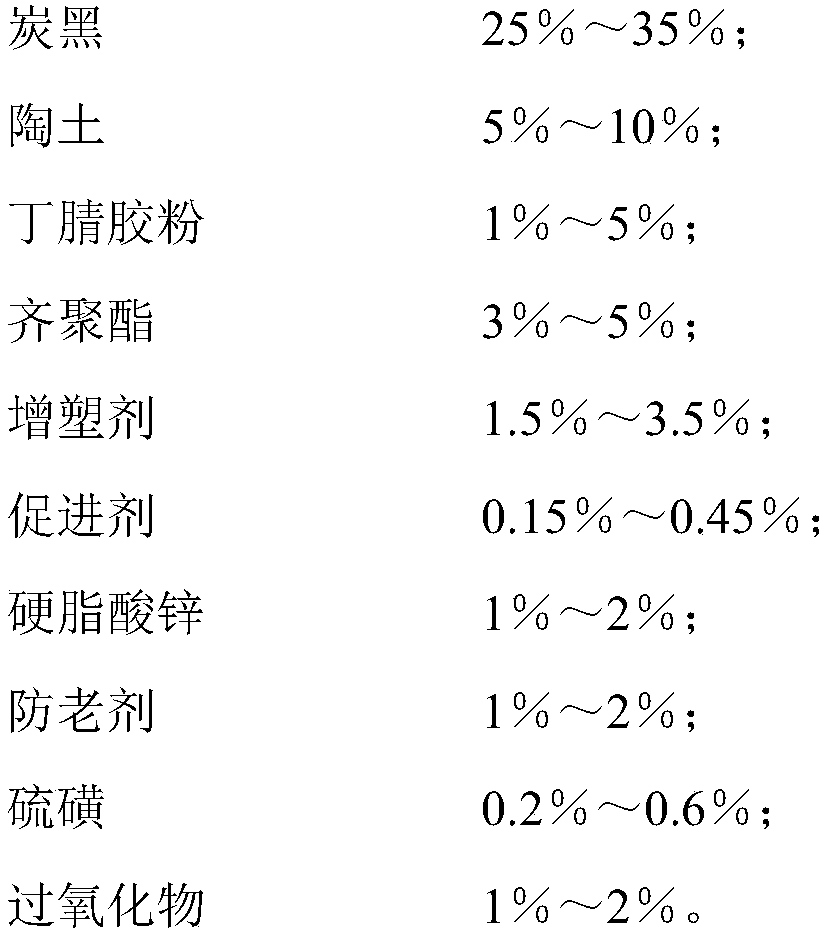

Method used

Image

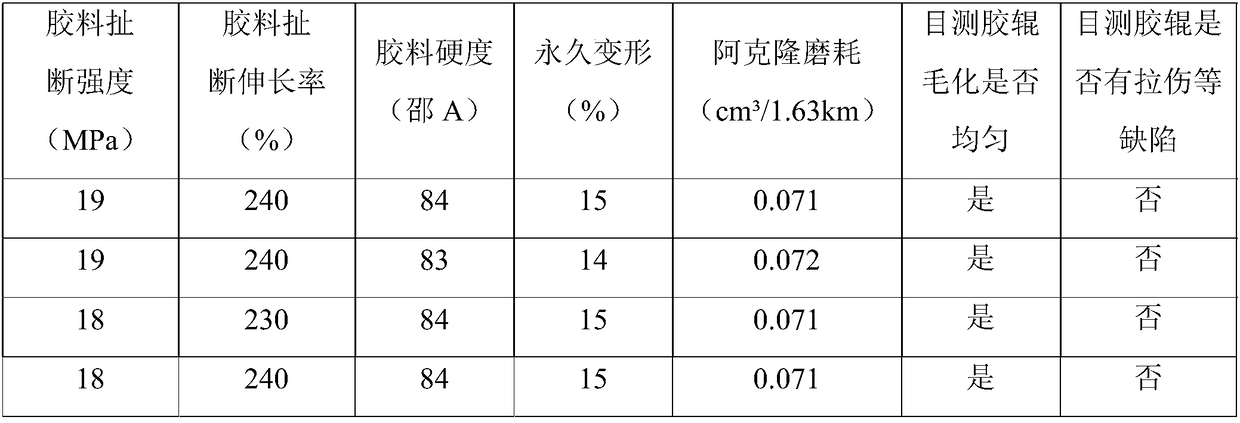

Examples

Embodiment 1

[0042] A kind of orange-peel-shaped rubber roller material of this embodiment and the method for making orange-peel-shaped rubber rollers using it, this embodiment produces 4 pieces of orange-peel-shaped rubber rollers with a specification of Φ250×1500mm in total, and the 4 pieces of orange-peel-shaped rubber rollers The material of the roller is made according to the composition and weight shown in Table 1, and the total weight of the components is 75kg.

[0043] Table 1

[0044] Composition

weight

Nitrile rubber

30kg

7.5kg

Gas-mixed carbon black

18.75kg

Clay

7.5kg

3.75kg

2.625kg

Plasticizer D-810

1.125kg

Dibenzothiazole disulfide

262.5g

37.5g

750g

Antiaging agent D

900g

Antiaging agent 4010NA

450g

150g

peroxide ...

Embodiment 2

[0061] A kind of orange-peel-shaped rubber roller material of this embodiment and the method for making orange-peel-shaped rubber rollers using it, this embodiment produces 4 pieces of orange-peel-shaped rubber rollers with a specification of Φ840×1600mm in total, and the 4 pieces of orange-peel-shaped rubber rollers The material of the roller is made according to the composition and weight shown in Table 3, and the total weight of the components is 75kg.

[0062] table 3

[0063] Composition

weight percentage

Nitrile rubber

36kg

General purpose carbon black

7.5kg

Gas-mixed carbon black

13.5kg

Clay

3.75kg

3kg

3.75kg

Plasticizer D-810

2.625kg

Dibenzothiazole disulfide

225g

75g

1.5kg

Antiaging agent D

675g

Antiaging agent 4010NA

450g

450g

perox...

Embodiment 3

[0080] A kind of orange-peel-shaped rubber roller material of this embodiment and the method for making orange-peel-shaped rubber rollers using it, this embodiment produces 4 pieces of orange-peel-shaped rubber rollers with a specification of Φ350×1500mm in total, and the 4 pieces of orange-peel-shaped rubber rollers The material of the roller is made according to the composition and weight shown in Table 5, and the total weight of the components is 75kg.

[0081] table 5

[0082] Composition

weight percentage

31.5kg

General purpose carbon black

8.25kg

Gas-mixed carbon black

16.5kg

Clay

6kg

Nitrile rubber powder

3.375kg

3.75kg

Plasticizer D-810

1.875kg

Dibenzothiazole disulfide

105g

45g

Zinc stearate

1.2kg

Antiaging agent D

450g

Antiaging agent 4010NA

450g

sulfur

450g

p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com