A kind of yarn and its preparation method and glove embryo, spun product

A yarn and product technology, applied in the direction of gloves, yarn, textiles and paper making, can solve the problems of single color gloves, wear resistance, tear resistance, cut resistance and puncture resistance, etc. In order to achieve the effect of strong wear resistance, excellent elasticity and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

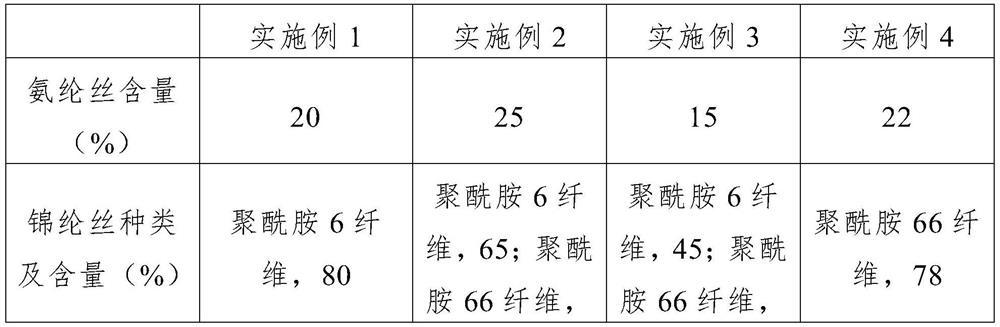

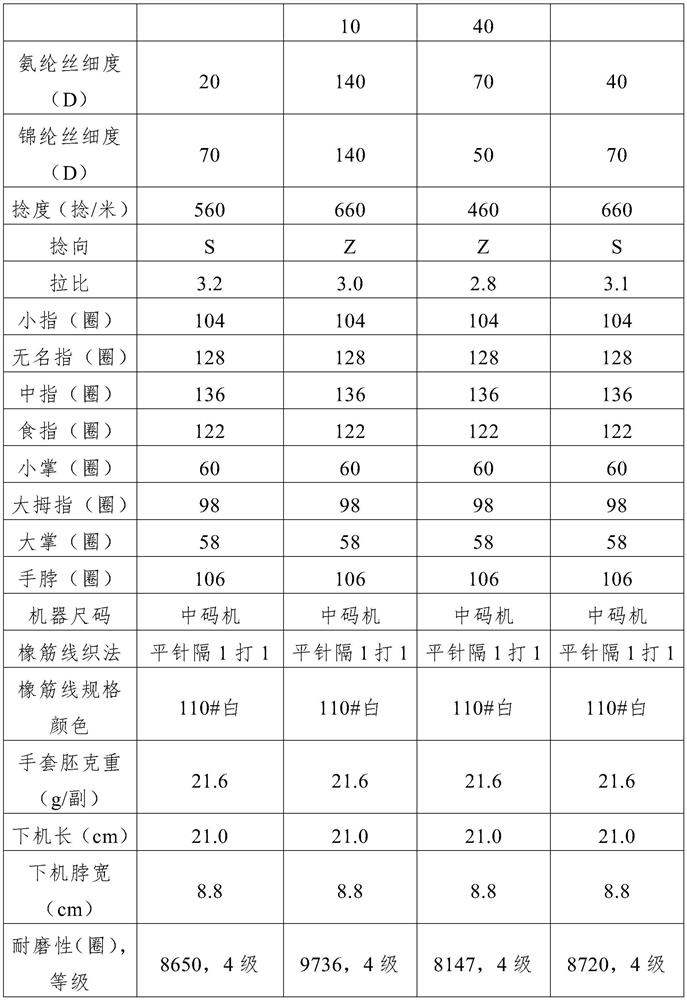

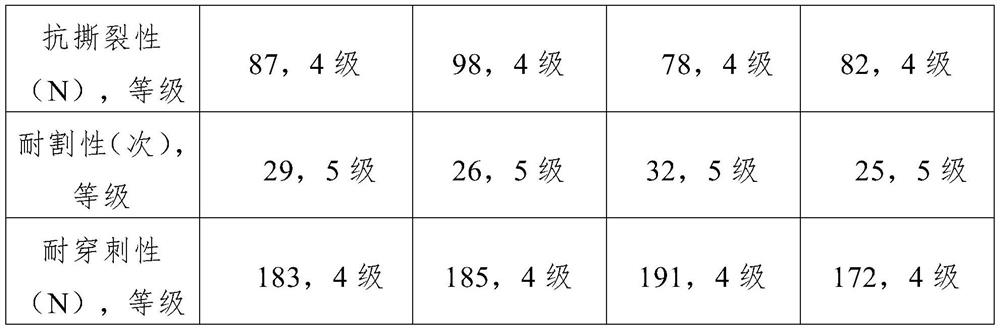

[0038] Embodiment 1-4 proposes a kind of nylon single-wrapped spandex yarn and its preparation method. The preparation method of nylon single-wrapped spandex yarn uses a strand of spandex yarn twisted into several spandex filaments as the core thread, and is used by a coating machine. A strand of nylon yarn twisted from several nylon filaments is used to cover the core wire in a single layer to prepare a nylon single-wrapped spandex yarn in which the spandex yarn is covered with a layer of nylon yarn. The preparation parameters are shown in Table 1.

[0039] The density of spandex fiber is 1-1.25g / cm 3 , has great elasticity, its elongation can be greater than 400%, even as high as 800%, and its rebound rate is 95%-99% when it is elongated by 500%. Generally speaking, in the molecular structure of spandex fiber, the greater the relative molecular mass of the soft segment, the higher the elasticity and rebound rate of the fiber. The breaking strength of spandex filament is 0.3...

Embodiment 5-8

[0079] Embodiment 5-8 proposes a kind of nylon double-wrapped spandex yarn and its preparation method. The preparation method of nylon double-wrapped spandex yarn uses a strand of spandex yarn twisted into several spandex filaments as the core thread, and is used by a coating machine. A strand of nylon yarn twisted from several nylon filaments is double-coated on the core wire to prepare a nylon double-wrapped spandex yarn with two layers of nylon yarn wrapped around the spandex yarn. The preparation parameters are shown in Table 2.

[0080] Using the nylon double-wrapped spandex yarn obtained in the above-mentioned Examples 5-8, the glove embryo was woven through a 15-needle medium-size knitting machine. During the process of weaving the glove embryo, the temperature was controlled at 28° C. and the humidity at 60%. The braided glove embryos were tested for abrasion resistance, tear resistance, cut resistance, puncture resistance and other properties according to the EN388 sta...

Embodiment 9-12

[0086] Embodiment 9-12 proposes a kind of spandex nylon air-covered yarn and its preparation method, the preparation method of nylon filament empty-covered yarn is, a strand of spandex yarn twisted into several spandex filaments and several nylon filaments The twisted strand of nylon yarn is drawn at the same time, and compressed air with a pressure of 1.5-3.5Pa is sprayed through the mesh nozzle to prepare spandex nylon empty-covered yarn. The preparation parameters are shown in Table 3.

[0087] Using the spandex nylon air-covered yarn obtained in the above-mentioned Examples 9-12, weave glove embryos through a 13-needle medium-size knitting machine. During the process of weaving glove embryos, control the temperature at 27°C and the humidity at 75%. The braided glove embryos were tested for abrasion resistance, tear resistance, cut resistance, and puncture resistance according to the EN388 standard. The test results are shown in Table 3.

[0088] table 3

[0089]

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com