Wear-resistant conductive shoe sole rubber as well as preparation method and application thereof

A technology of rubber and conductive carbon black, applied in the field of rubber processing, can solve the problems of serious flying loss, high manufacturing cost, unstable electrical conductivity of conductive rubber, etc., and achieve the effects of wide source of materials, good use effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

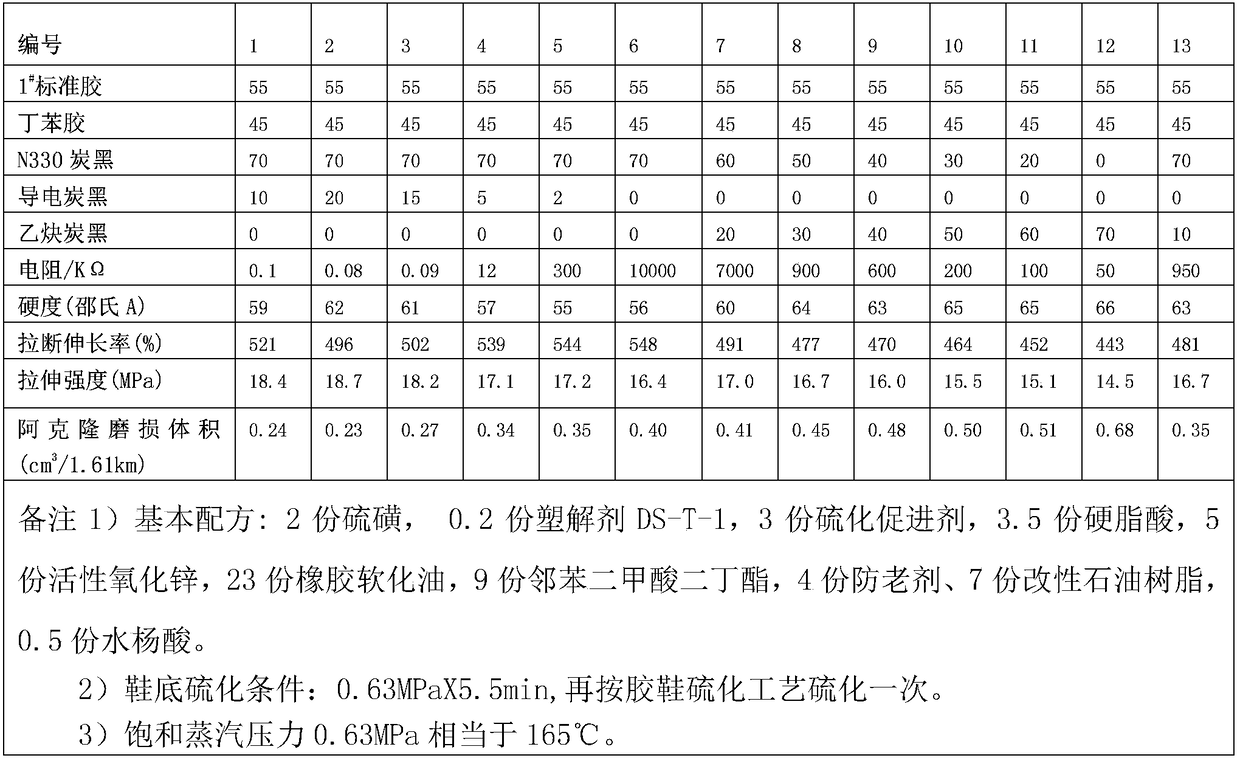

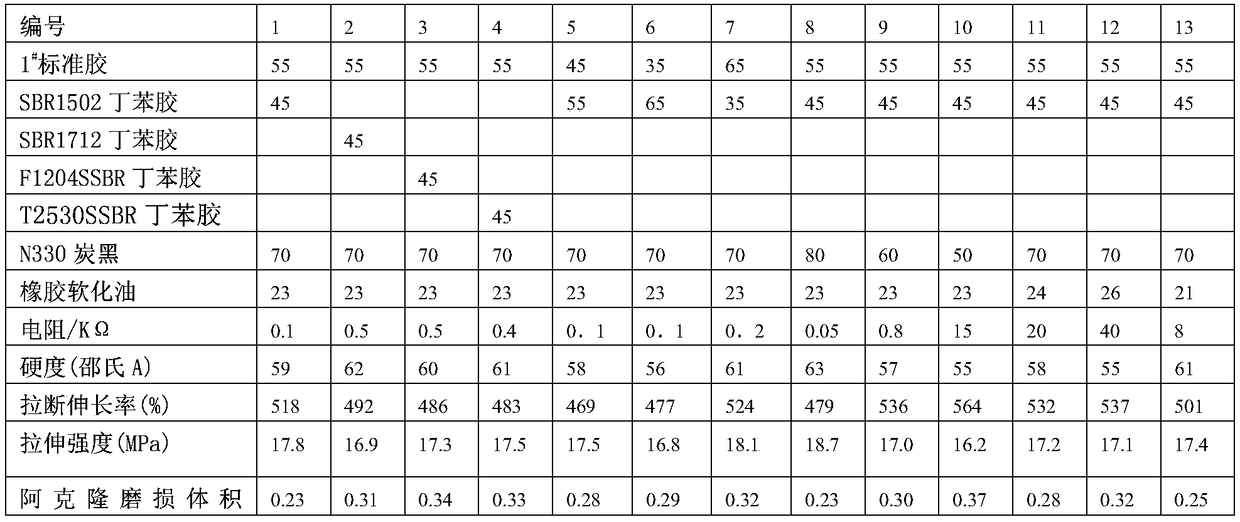

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 of the present invention: wear-resistant conductive shoe sole rubber, calculated by weight fraction, a more preferred technical solution is, calculated by weight fraction, including 55 parts of standard rubber, 45 parts of styrene-butadiene rubber, 2 parts of sulfur, and 0.2 part of peptized Agent DS-T-1, 3 parts of vulcanization accelerator, 3.5 parts of stearic acid, 5 parts of active zinc oxide, 23 parts of rubber softening oil, 9 parts of dibutyl phthalate, 70 parts of N330 carbon black, 4 parts of anti-aging agent, 7 parts of modified petroleum resin, 0.5 part of salicylic acid and 10 parts of conductive carbon black.

[0036] The preparation method of wear-resistant conductive shoe sole rubber, 1) Preparation of plasticized rubber: 45 parts of standard rubber and 0.2 part of peptizer DS-T-1 are pressed in an internal mixer at a temperature of 100 to 130 ° C for 8 to 10 minutes , discharged to the open rubber mixing machine, covered with rollers, and k...

Embodiment 2

[0038] Embodiment 2 of the present invention: wear-resistant conductive shoe sole rubber, calculated by weight fraction, a more preferred technical solution is, calculated by weight fraction, including 60 parts of standard rubber, 40 parts of styrene-butadiene rubber, 2 parts of sulfur, and 0.2 part of peptized Agent DS-T-1, 3 parts of vulcanization accelerator, 3.5 parts of stearic acid, 5 parts of active zinc oxide, 23 parts of rubber softening oil, 9 parts of dibutyl phthalate, 60 parts of N330 carbon black, 4 parts of anti-aging Agent, 7 parts of modified petroleum resin, 0.5 part of salicylic acid and 15 parts of conductive carbon black.

[0039] The preparation method and application are the same as in Example 1.

Embodiment 3

[0040] Embodiment 3 of the present invention: wear-resistant conductive shoe sole rubber, calculated by weight fraction, a more preferred technical solution is, calculated by weight fraction, including 55 parts of standard rubber, 45 parts of styrene-butadiene rubber, 2 parts of sulfur, and 0.2 part of peptized Agent DS-T-1, 3 parts of vulcanization accelerator, 3.5 parts of stearic acid, 5 parts of active zinc oxide, 15 parts of rubber softening oil, 18 parts of dibutyl phthalate, 70 parts of N330 carbon black, 4 parts of anti-aging agent, 7 parts of modified petroleum resin, 0.5 part of salicylic acid and 10 parts of conductive carbon black.

[0041] The preparation method and application are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com