A polyurethane composition and a saturable reactor using the same

A reactor, polyurethane technology, applied in the direction of polyurea/polyurethane adhesive, transformer/inductor cooling, electrical components, etc., can solve the problems of reducing the service life of saturated reactors, poor heat dissipation, and iron core heating, etc. The effect of improving the service life, high thermal conductivity, and reducing the temperature of the iron core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

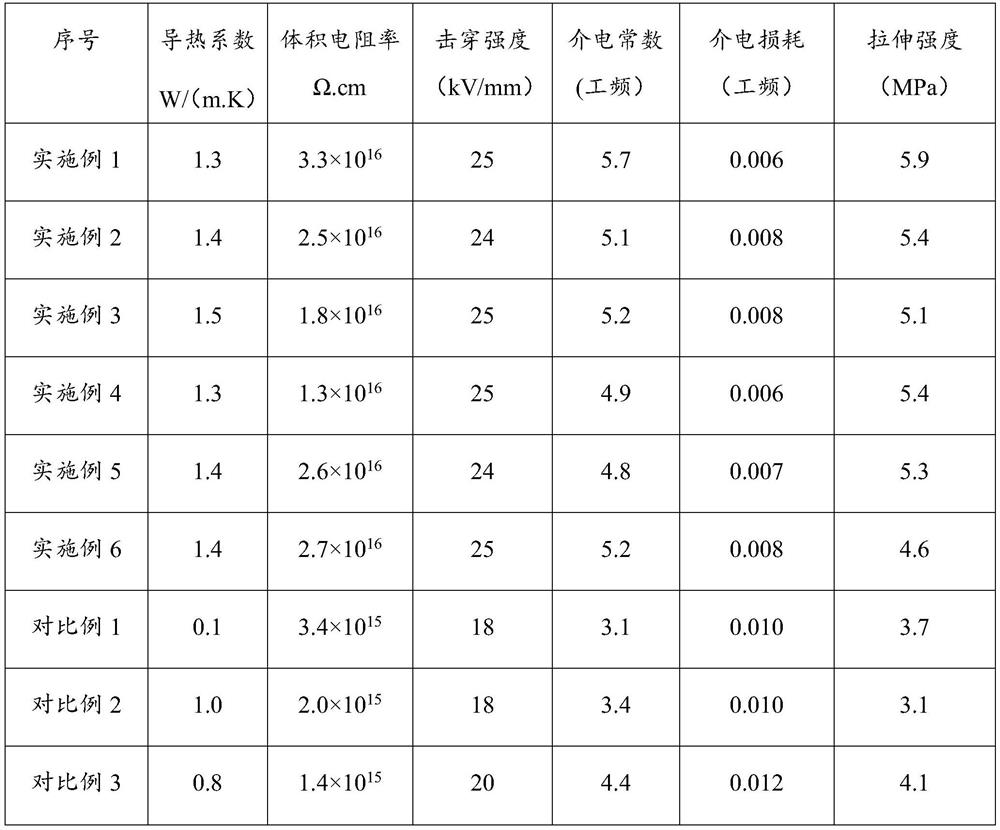

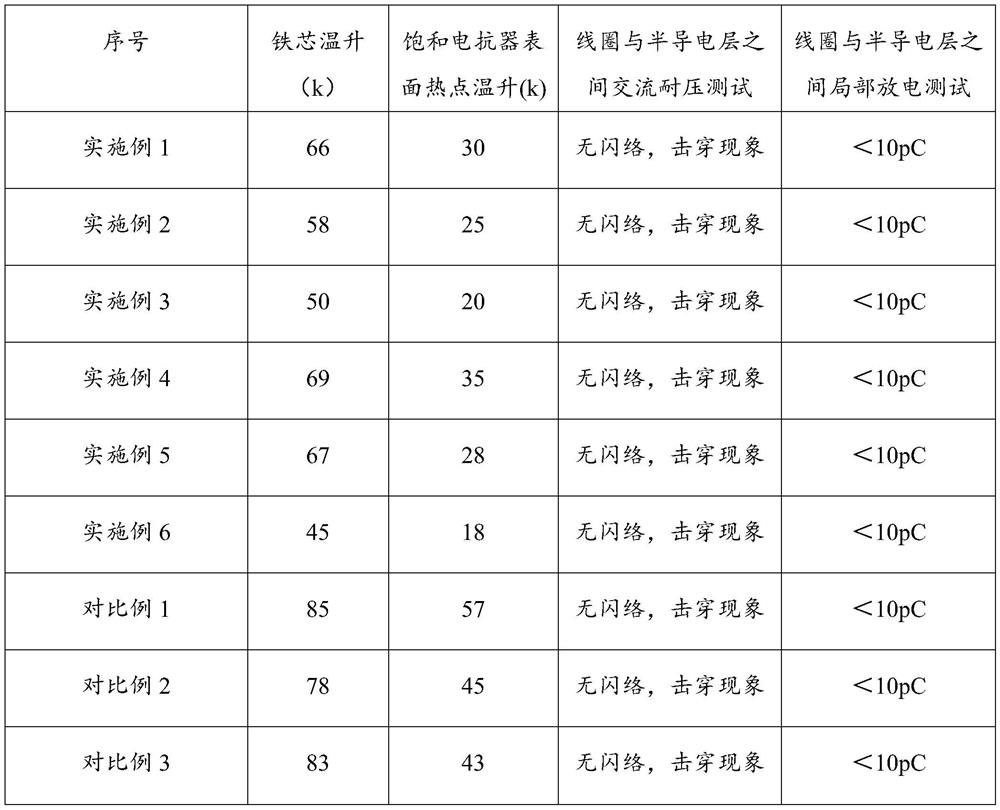

Examples

Embodiment 1

[0023] (1) The preparation technology of polyurethane composition in the present embodiment, comprises the following steps:

[0024] Take 20g of polyether polyols, 2g of flame retardants, 0.5g of catalysts and 120g of inorganic fillers, mix them uniformly at a temperature of 45°C and a vacuum of 150Pa, and then add 100g of diphenylmethane diisocyanate And the inorganic filler of 80g, be 35 ℃ in temperature, under the condition that vacuum degree is 300Pa, mix homogeneously, make polyurethane composition; Wherein, described inorganic filler is aluminum oxide, wherein the ratio of the parts by weight of inorganic filler is 1: 1.1 Alumina particles with a particle size D50 value between 45.73 μm and alumina particles with a particle size D50 value between 10.25 μm, the flame retardant is dibromoneopentyl glycol, and the catalyst is 1,8-diazepine Cyclo(5.4.0)undec-7-ene.

[0025] (2) The molding process of the saturable reactor in the present embodiment comprises the following st...

Embodiment 2

[0031] (1) The preparation technology of polyurethane composition in the present embodiment, comprises the steps:

[0032] Take 30g of polyether polyols, 0.5g of flame retardants, 0.8g of catalysts and 75g of inorganic fillers, mix them uniformly at a temperature of 60°C and a vacuum of 200Pa, then add 100g of diphenylmethane di The isocyanate and 75g of inorganic filler are uniformly mixed at a temperature of 50°C and a vacuum of 200Pa to prepare a polyurethane composition; wherein, the inorganic filler includes a particle size D50 value of 1:1.3 in parts by weight The large-particle inorganic filler with a particle size of 31.45 μm and the small-particle inorganic filler with a particle size D50 value of 14.97 μm, the flame retardant is dibromoneopentyl glycol, and the catalyst is 1,8-diazacyclo(5.4.0)11 Carb-7-ene, the inorganic filler is alumina.

[0033] (2) The molding process of the saturable reactor in this embodiment differs from the molding process of Embodiment 1 o...

Embodiment 3

[0035] (1) The preparation technology of polyurethane composition in the present embodiment, comprises the steps:

[0036]Take 25g of polyether polyols, 1.2g of flame retardants, 1g of catalysts and 120g of inorganic fillers, mix them uniformly at a temperature of 55°C and a vacuum of 150Pa, and then add 110g of diphenylmethane diisocyanate and 80g of inorganic fillers, mixed uniformly under the condition that the temperature is 30°C and the vacuum degree is 250Pa, and the polyurethane composition is prepared; wherein, the inorganic fillers include a particle size D50 value of 1:1.3 in parts by weight The large particle inorganic filler between 40.56 μm and the small particle inorganic filler with a particle size D50 value of 10.49 μm, the flame retardant is dibromoneopentyl glycol, and the catalyst is 1,8-diazacycle (5.4.0) deca One carbon-7-ene, the inorganic filler is alumina.

[0037] (2) The molding process of the saturable reactor in this embodiment differs from that of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| loss value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com