Kitchen waste oil-water separation device

An oil-water separation device and kitchen technology, which is applied in the direction of grease/oily substance/floating matter removal device, water treatment parameter control, heating water/sewage treatment, etc., can solve problems such as waste of resources, easy solidification of grease, and complex structural design. Achieve the effects of increasing oil-water separation, reducing kinematic viscosity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

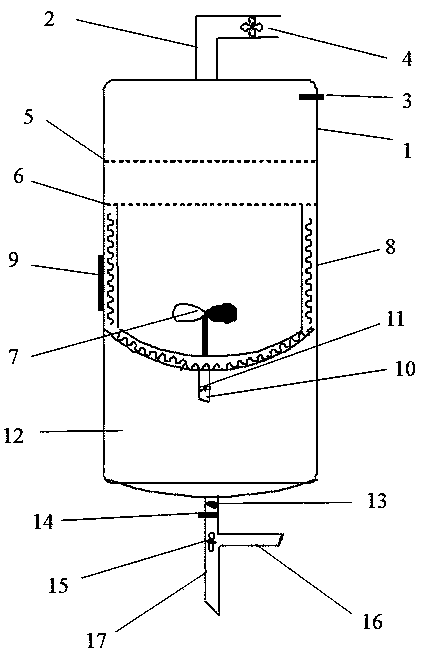

[0021] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0022] A kitchen waste oil-water separation device includes a body 1, a feed inlet 2 is provided at the upper end of the body, a water outlet pipe 16 and an oil outlet pipe 17 are provided at the lower end, and the body 1 is sequentially provided with a primary filter plate 5 and a secondary filter from top to bottom. Plate 6, stirrer 7, heating system 8, oil-water mixture discharge pipe 10 and separation box 12. The upper part of the body 1 is also provided with an electromagnetic sensor 3, and the heating system 8 is also provided with a temperature control device 9.

[0023] The said feed inlet is equipped with an induction switch a4.

[0024] The primary filter plate 5 is provided with a plurality of circular small holes with a diameter of 5 mm-10 mm, and the secondary filter plate 6 is provided with circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com