Esterification reactor and esterification reaction method based on solid catalyst

A solid catalyst and reaction device technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of reduced life of circulating pumps, limitation of catalyst dosage, long settling time, etc., to reduce wear and improve ester The effect of improving the efficiency and improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the main structural features and advantages of the reaction device of the present invention will be respectively introduced through specific embodiments.

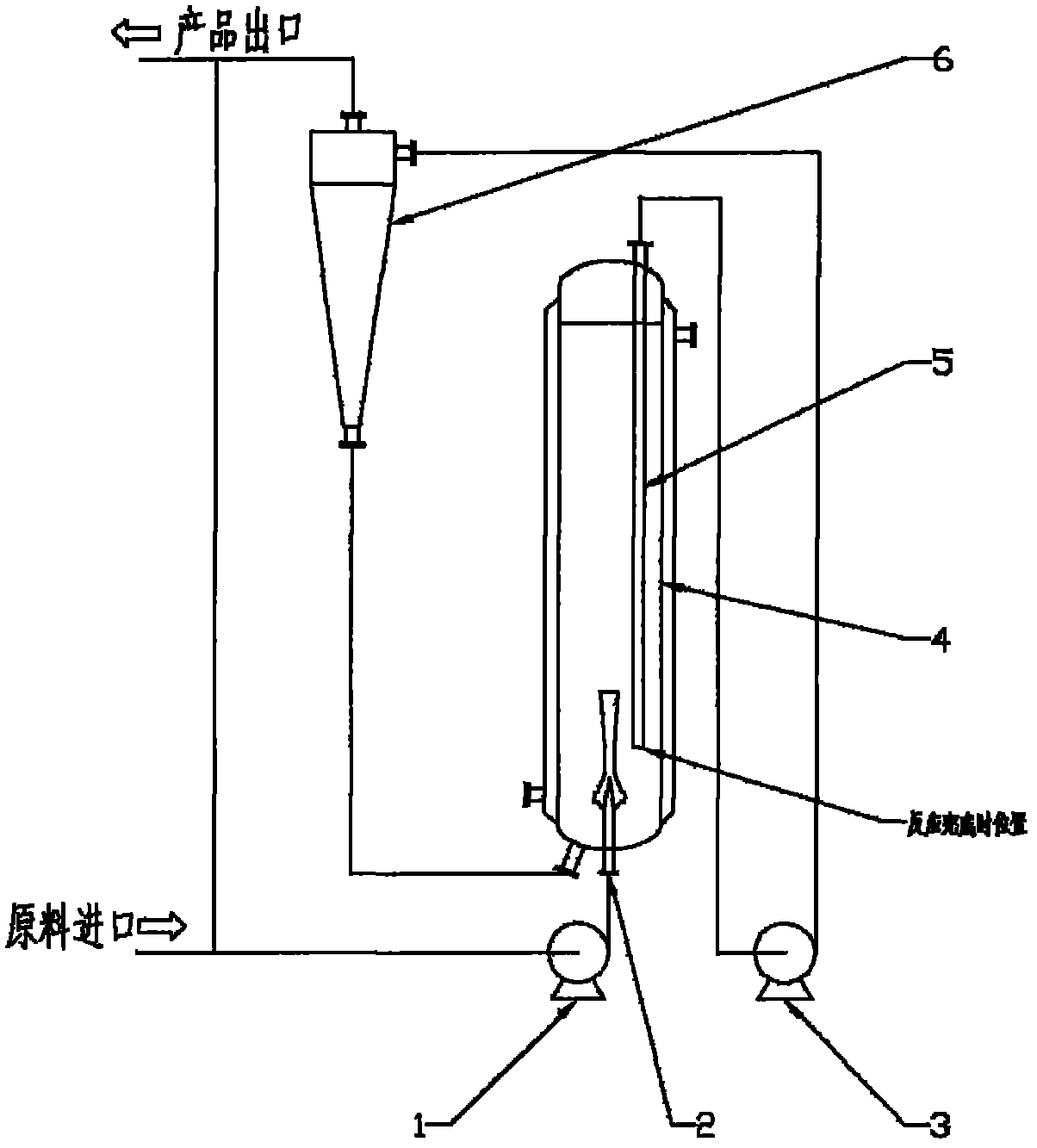

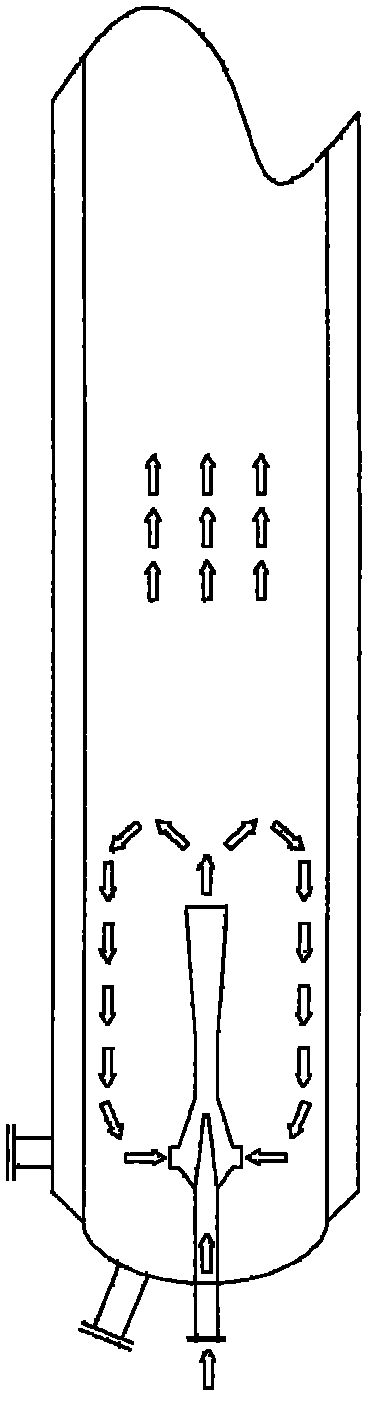

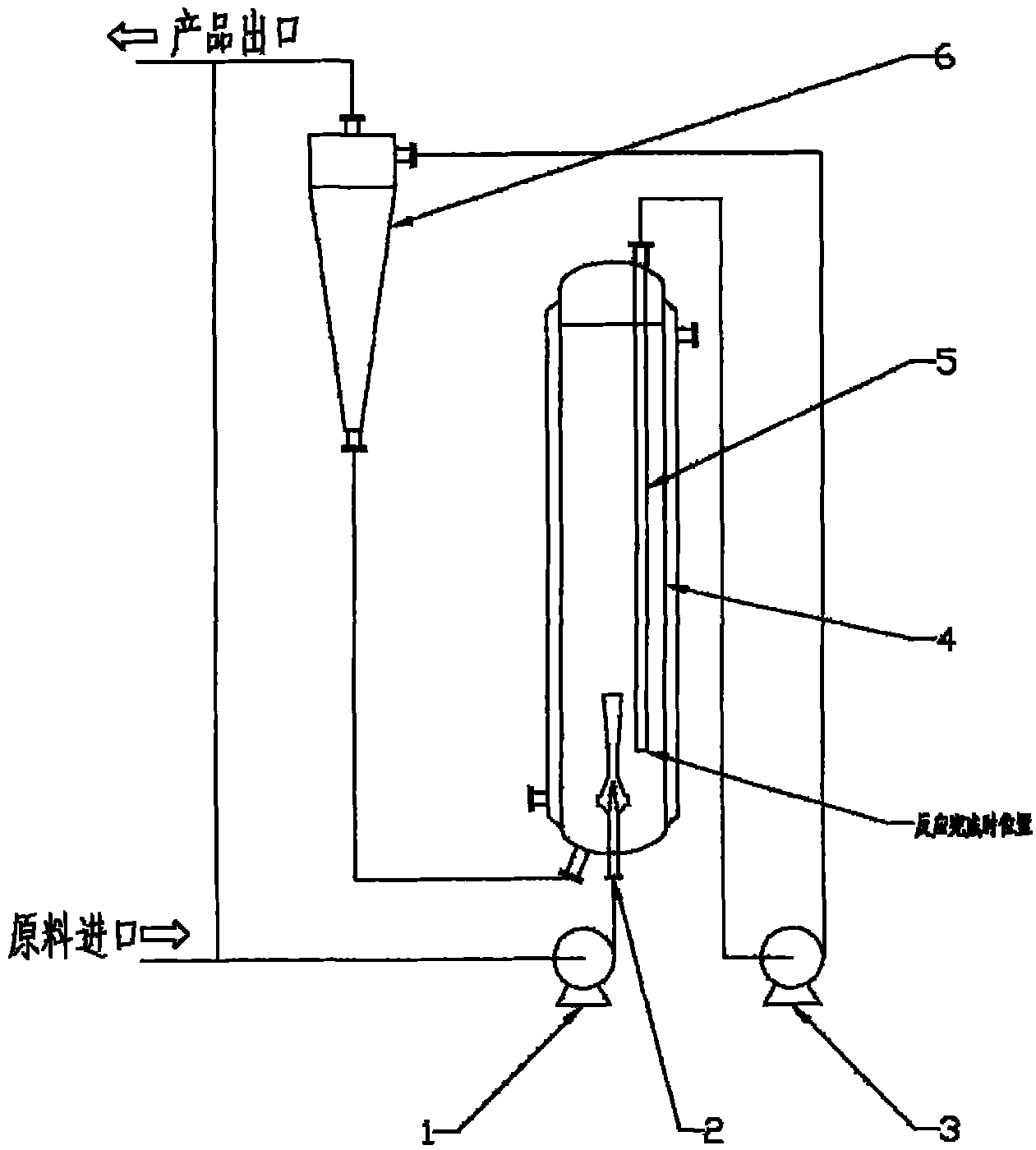

[0015] figure 1 It is a schematic diagram of an esterification reaction device in a preferred embodiment of the present invention. In the reaction device, according to the delivery order of the feed liquid, there are feed pump 1, suction injector 2, reaction tube 4, lifting discharge tube 5, circulation pump 3, and hydrocyclone 6. The above parts are connected through pipelines as shown in the figure, and valves can be set to adjust the flow and pressure.

[0016] The light phase outlet of the hydrocyclone, that is, the upper outlet, is connected to the feed pump, and is used as the crude product outlet when the reaction ends; the heavy phase outlet of the hydrocyclone, that is, the lower outlet, is connected to the catalyst reflux inlet at the bottom of the reaction tube, also Catalyst can be recovere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com