Hydraulic energy absorption anti-creeper for train

An anti-climber and hydraulic technology, applied in the direction of railway vehicle wheel guards/buffers, railway car body parts, transportation and packaging, etc., can solve the problem of anti-climber partial load failure, low energy absorption efficiency, and controllable compression deformation Poor performance and other problems, to achieve maximum energy absorption and impact force level adjustable, large buffer energy absorption effect, good anti-eccentric load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

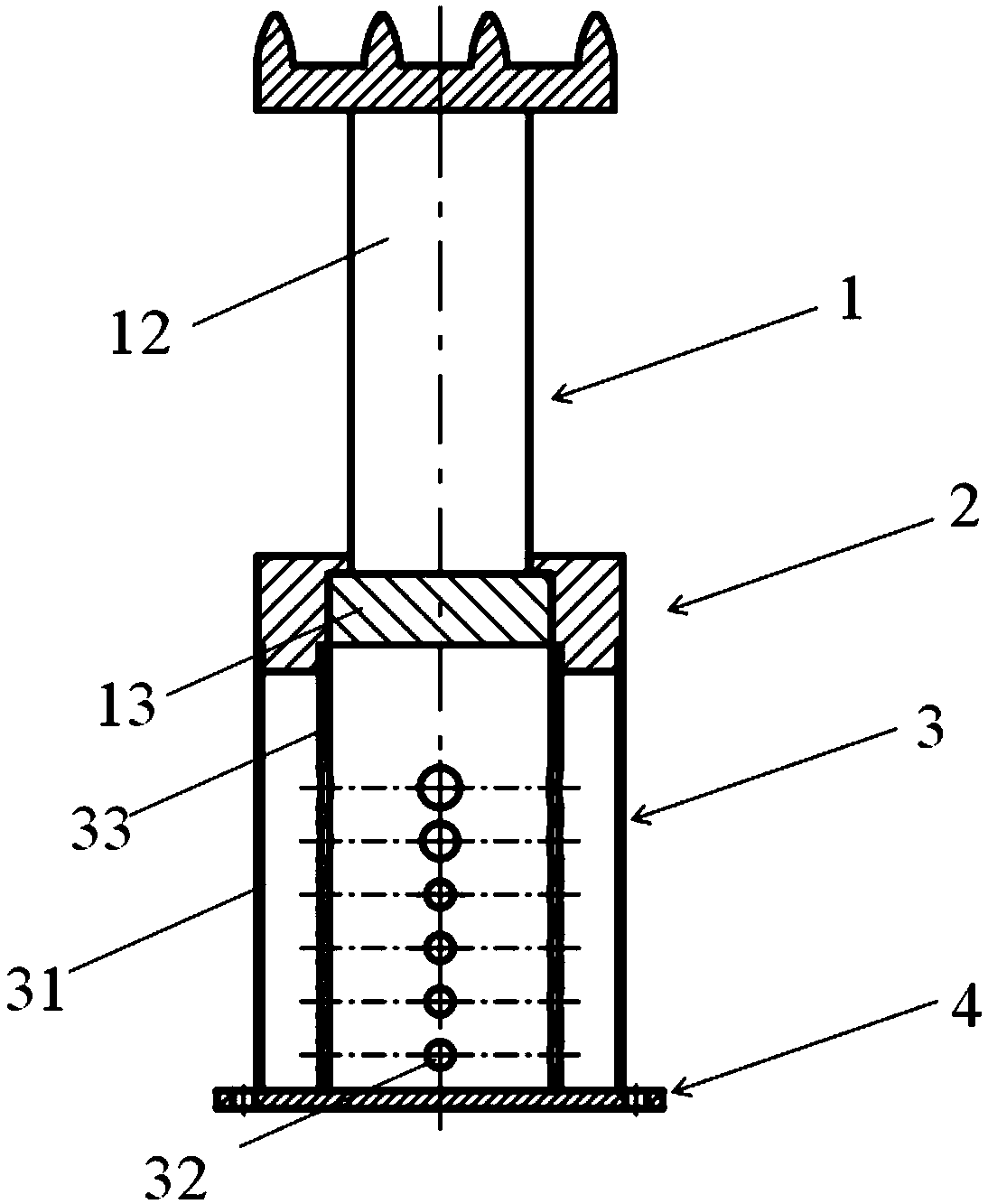

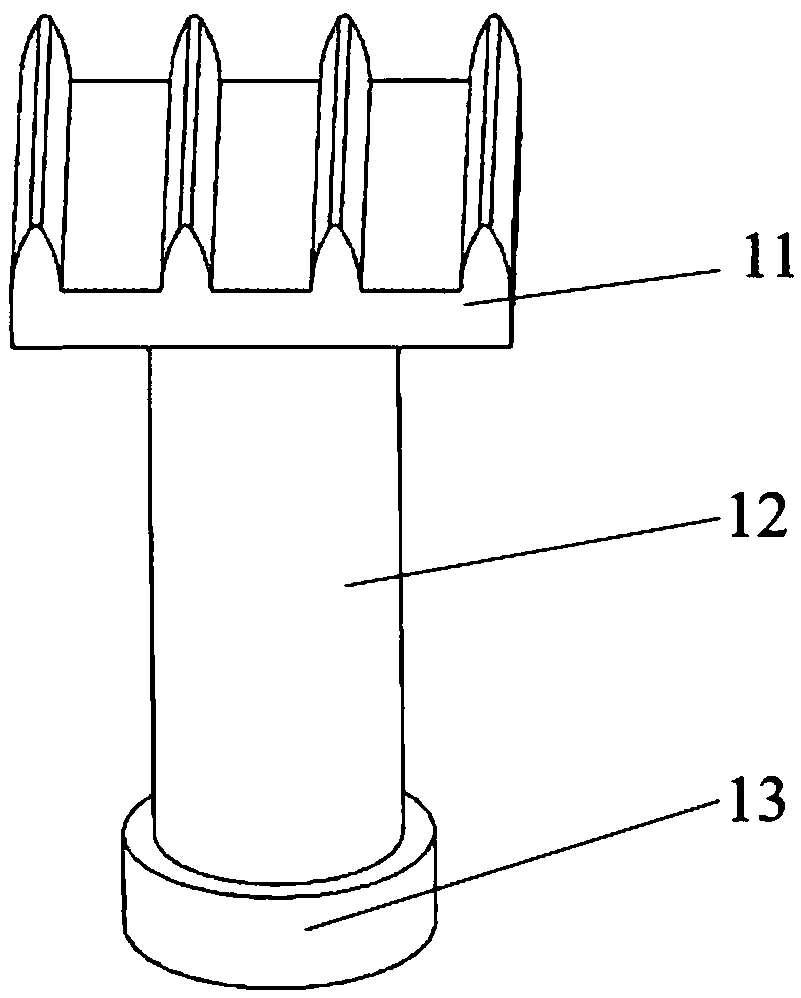

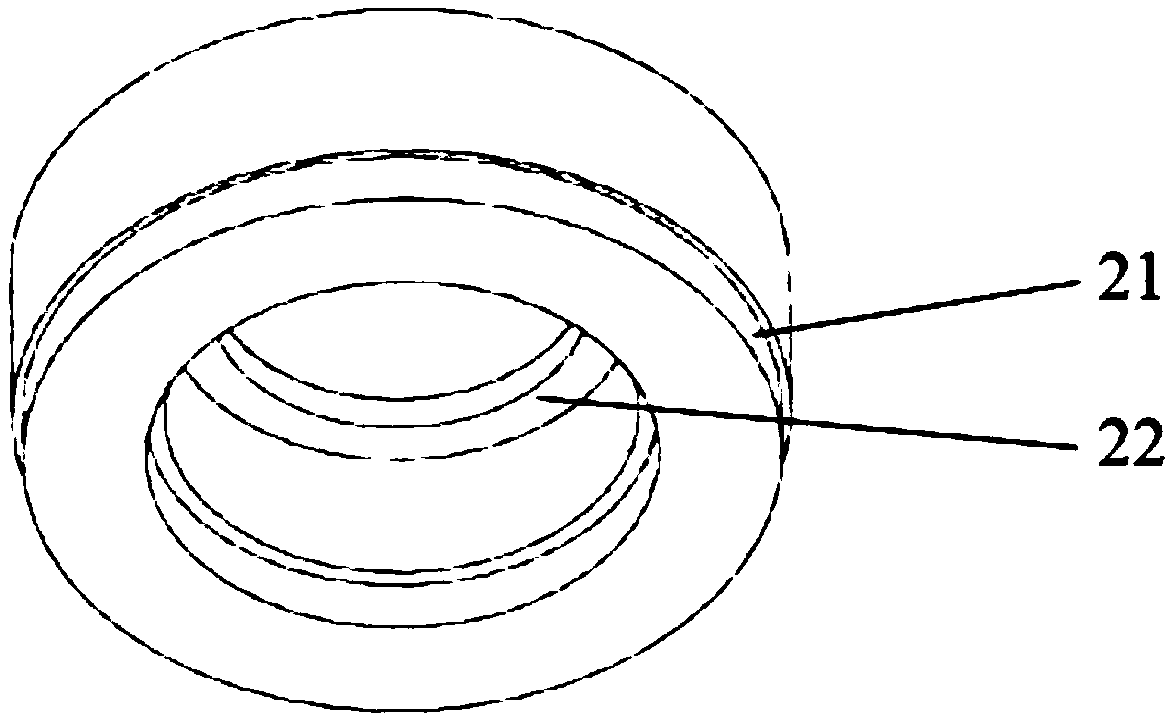

[0036] like Figure 1-Figure 7 As shown, the present invention discloses a train hydraulic energy-absorbing anti-climbing device, which is mainly composed of four parts: Anti-climbing teeth 11, piston rod 12, and piston 13 are composed, wherein, anti-climbing teeth 11 and piston 13 are arranged at both ends of piston rod 12, anti-climbing teeth 11 are arranged on a metal plate, and anti-climbing teeth 11 are 4 parallel , In this embodiment, in order to reduce the weight of the entire anti-climber, the piston rod 12 is designed as a hollow rod structure with a hollow interior. The hydraulic cylinder part 3 includes an inner sleeve 33 and an outer sleeve 31 coaxially welded on the installation base plate 41 of the installation base 4 (the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com