Leather slitting machine

A slitting machine and leather technology, which is applied in the mechanical processing of small raw hides/large raw hides/leather/furs, leather punching/punching/cutting, small raw hides/large raw hides/leather/fur processing, etc. The problems of leveling, top speed, and the width of the leather strip cannot be adjusted, so as to achieve the effect of simple structure and small equipment volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

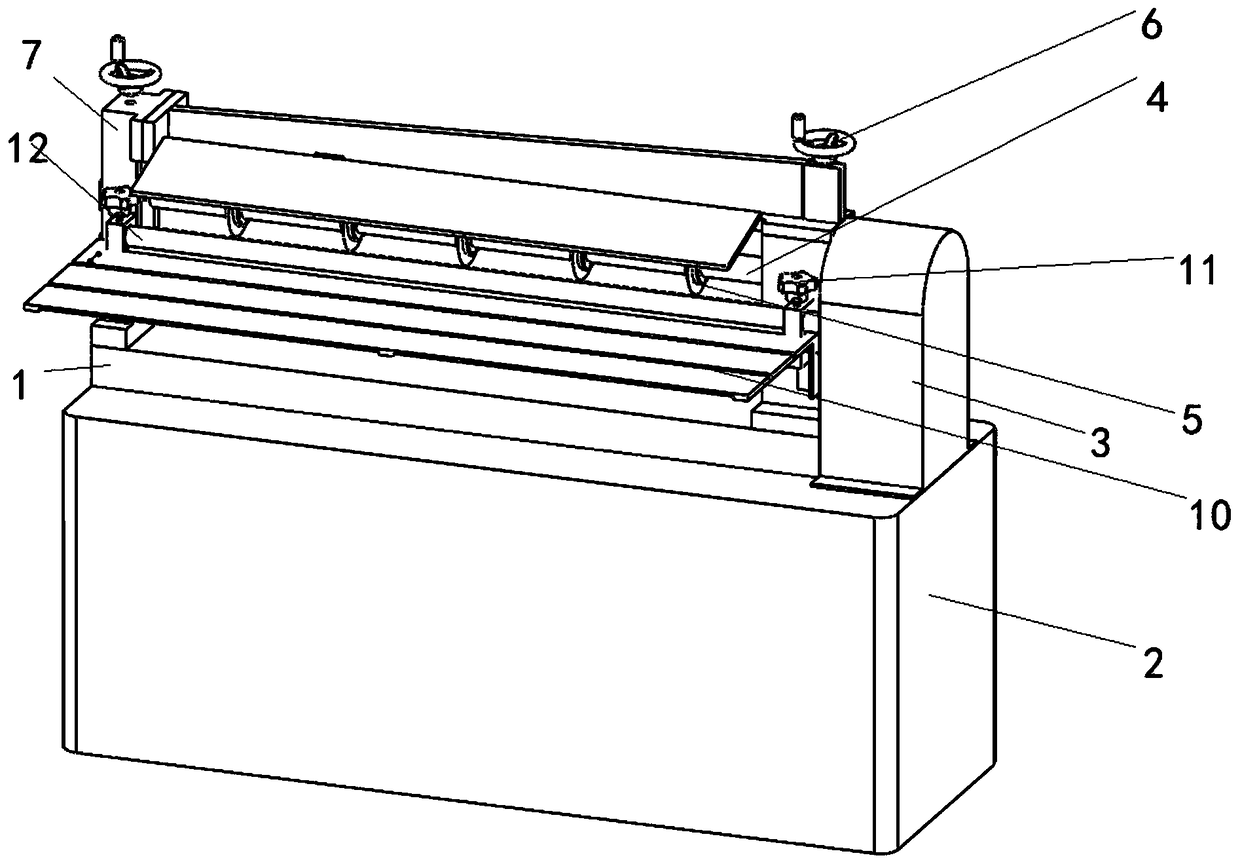

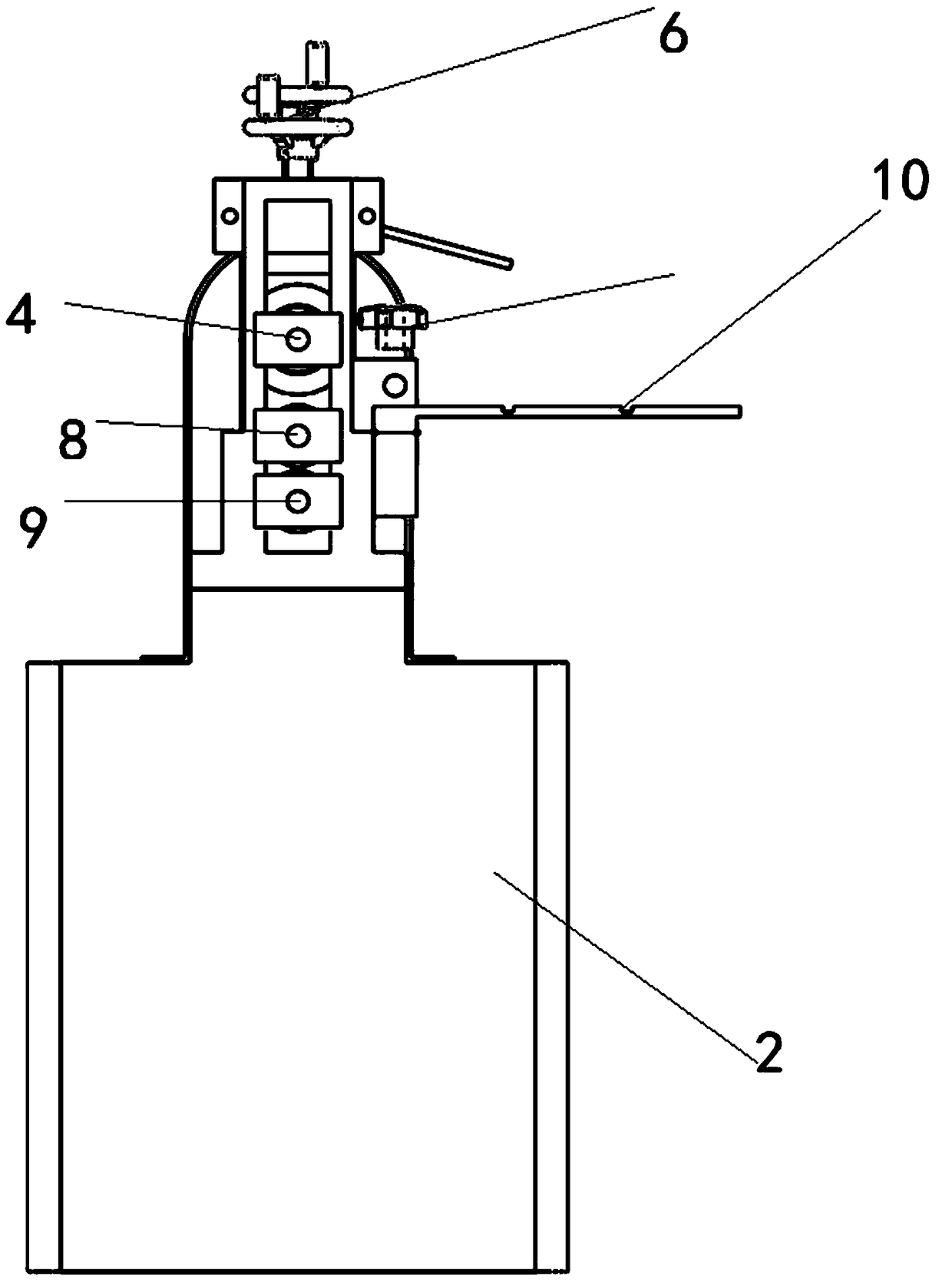

[0019] see figure 1 and figure 2 , a kind of leather slitting machine described in the present invention, comprises frame 1, base 2, drive box 3, drive shaft 4, material cutting circular blade 5, air pressure valve 6, air cylinder 7, main power shaft 8, driven power shaft 9, storage plate 10, adjusting nut 11; described frame 1 is provided with driving box 3, and described driving box 3 is provided with drive motor 301, and the drive shaft 4 of described drive motor 301 is provided with cutting Material circular blade 5, a plurality of material cutting circular blades 5 are installed on the described driving shaft 4, the surface of the described driving shaft 4 is symmetrically provided with two shafts, and the described cutting material circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com