Coated sand for medium thickness stainless steel castings

A technology of stainless steel and coated sand, applied in casting molds, casting molding equipment, metal processing equipment, etc., can solve the problems of affecting the dimensional accuracy of castings, unable to prepare stainless steel castings, etc., and achieve the effect of convenient operation, clear outline and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Weigh raw materials: Pearl sand 50kg, Hainan sand 30kg, white corundum 15kg, iron sand 5kg, phenolic resin 1.8kg, urotropine 0.306kg, calcium stearate 0.144kg; said pearl sand, Hainan sand, white corundum and iron sand As raw sand, its particle size is 70 / 140 mesh; the ratio is shown in Table 1;

[0016] Table 1

[0017] Mesh 70 mesh 100 mesh 120 mesh 140 mesh Proportion wt% 22.7 52.8 20.2 4.3

[0018] Mix Baozhu sand, Hainan sand, white corundum and iron sand evenly as raw sand, keep warm at 200°C for 15 minutes, wait for the temperature of the raw sand to drop to 135°C, add phenolic resin, stir for 90 seconds, then add urotropine and stearin Calcium acid is stirred, cooled, crushed, and then sieved to obtain coated sand for medium-thickness stainless steel castings.

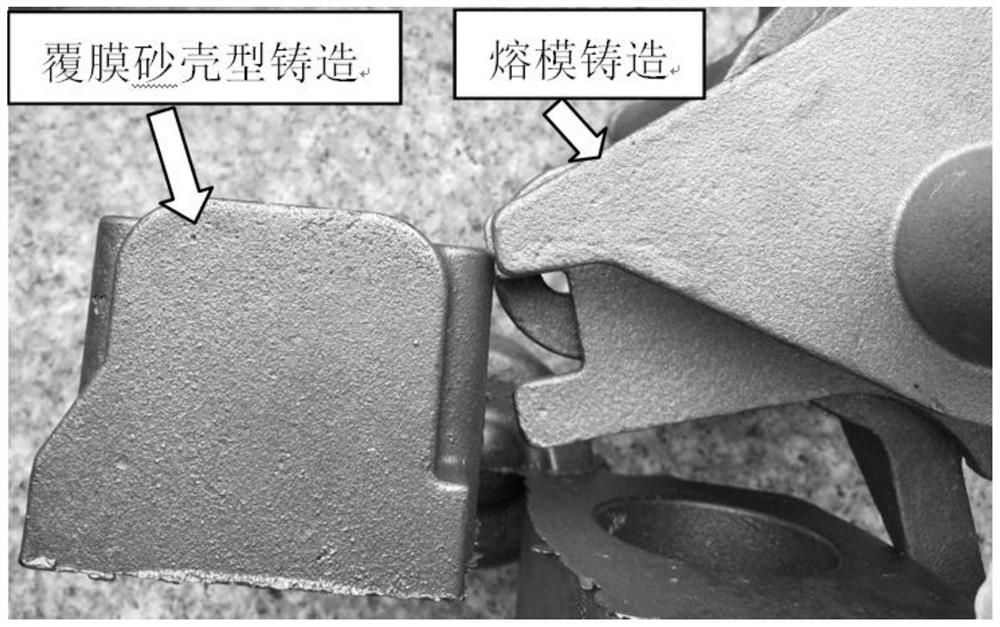

[0019] figure 1 It is a comparison chart of the surface quality of coated sand shell casting and investment casting stainless steel castings. The thickness of the casti...

Embodiment 2

[0021] Weigh raw materials: Pearl sand 50kg, Hainan sand 35kg, white corundum 12kg, iron sand 3kg, phenolic resin 1.6kg, urotropine 0.304kg, calcium stearate 0.096kg; said pearl sand, Hainan sand, white corundum and iron sand As raw sand, its particle size is 70 / 140 mesh; the ratio is shown in Table 1;

[0022] Mix Baozhu sand, Hainan sand, white corundum and iron sand evenly as raw sand, keep warm at 200°C for 20 minutes, wait for the temperature of the raw sand to drop to 125°C, add phenolic resin, stir for 100 seconds, then add urotropine and stearin Calcium acid is stirred, cooled, crushed, and then sieved to obtain coated sand for medium-thickness stainless steel castings. The coated sand has the properties of high strength, high temperature resistance, and low gas generation. It can cast stainless steel castings with a thickness of 10mm-40mm and a size of 800mm. It is suitable for stainless steel castings with a pouring temperature greater than 1650°C. The surface qualit...

Embodiment 3

[0024] Weigh raw materials: Pearl sand 45kg, Hainan sand 38kg, white corundum 3kg, iron sand 4kg, phenolic resin 1.7kg, urotropine 0.34kg, calcium stearate 0.068kg; said pearl sand, Hainan sand, white corundum and iron sand As raw sand, its particle size is 70 / 140 mesh; the ratio is shown in Table 1;

[0025] Mix Baozhu sand, Hainan sand, white corundum and iron sand evenly as raw sand, keep warm at 200°C for 18 minutes, wait for the temperature of the raw sand to drop to 130°C, add phenolic resin, stir for 95 seconds, then add urotropine and stearin Calcium acid is stirred, cooled, crushed, and then sieved to obtain coated sand for medium-thickness stainless steel castings. The coated sand has the properties of high strength, high temperature resistance, and low gas generation. It can cast stainless steel castings with a thickness of 10mm-40mm and a size of 800mm. It is suitable for stainless steel castings with a pouring temperature greater than 1650°C. The surface quality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com