A kind of baked potato essence and preparation method thereof

A technology for roasting potatoes and essence, applied in the field of food processing, can solve the problems of undiscovered patent publications, difficulties and the like, and achieve the effects of enhancing the characteristic flavor of potatoes, supplementing losses, and stabilizing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

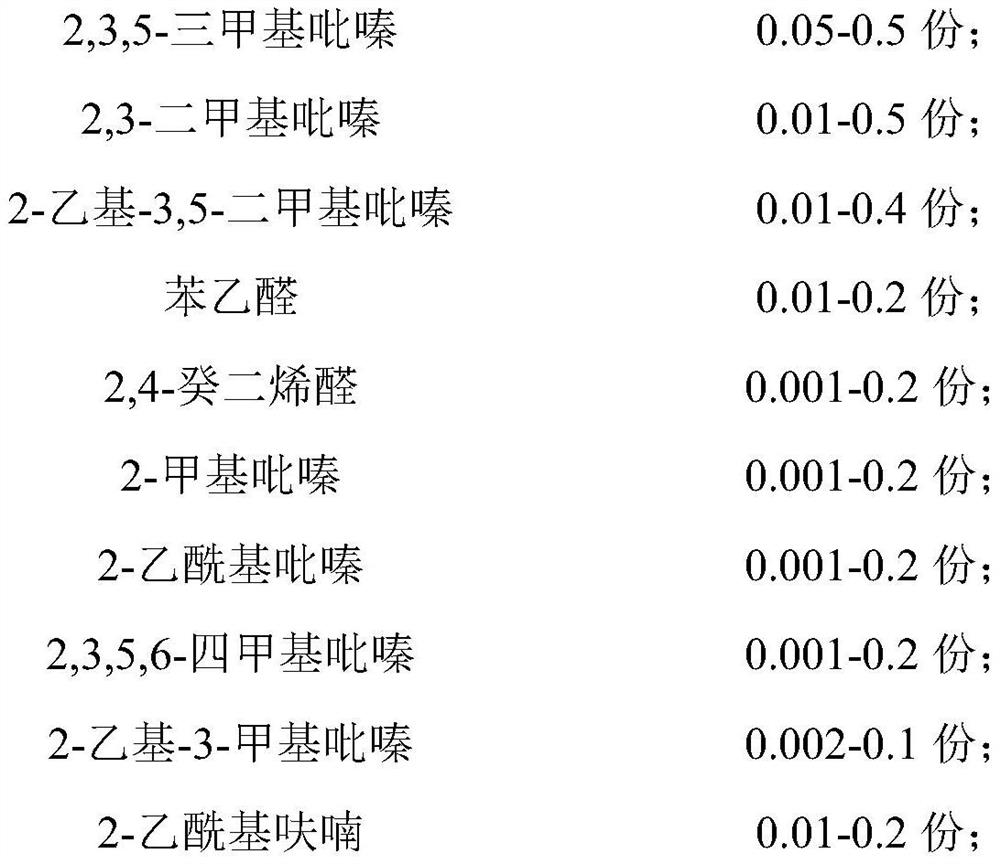

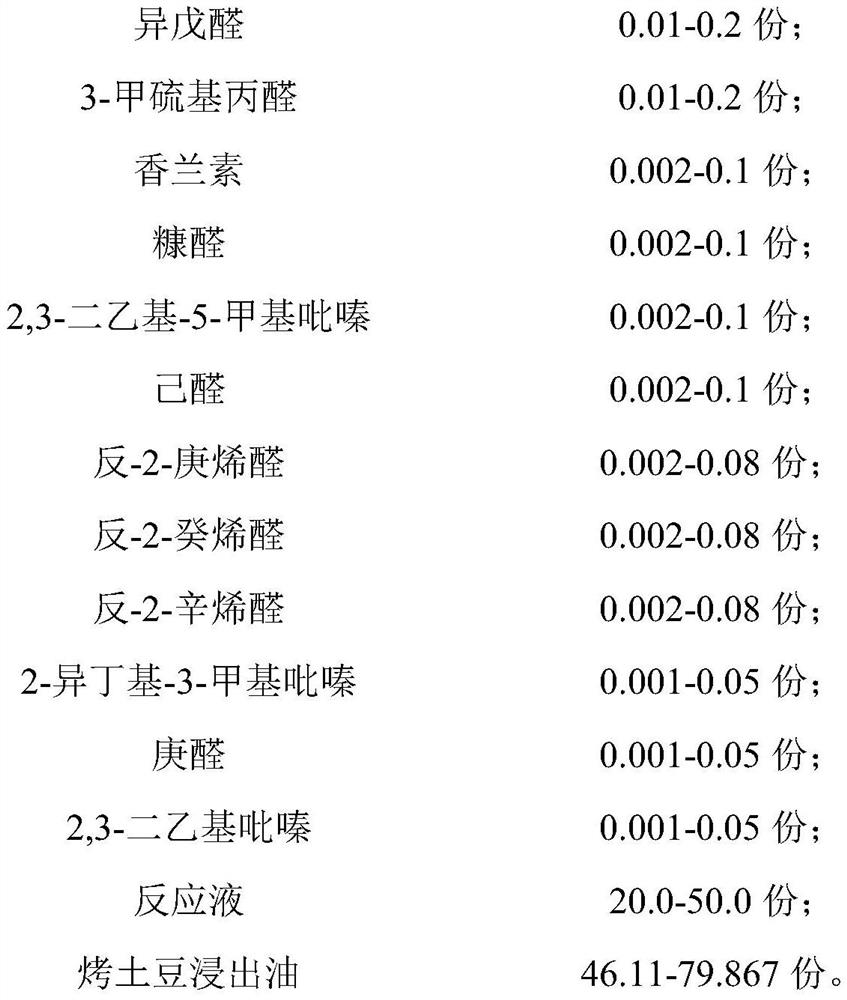

[0024] A kind of baked potato essence, the formula of producing 100kg baked potato essence is as shown in table 1:

[0025] Table 1 Recipe table

[0026]

[0027]

[0028] Wherein, the preparation method of described reaction solution is:

[0029] 1 part of xylose, 1 part of glucose, 1.5 parts of arginine, 0.5 part of methionine, 0.5 part of proline, 50 parts of water, 50 parts of soybean oil, wherein the total mass of reducing sugar is equal to the total mass of amino acids, and the raw materials are weighed according to the formula Finally, the Maillard reaction is carried out at a temperature of 100-150° C. for 1-3 hours. After the reaction is completed, the water layer is discarded and the oil layer is collected, which is the reaction liquid.

[0030] Wherein, the preparation method of described baked potato leaching oil is:

[0031] Slice the potatoes, soak them in clean water for 10-30 minutes, wrap them in tin foil and put them in the oven at 180-250°C for 30-80...

Embodiment 2

[0035] A roasted potato essence, its composition and parts by weight are:

[0036]

[0037] Preferably, the preparation method of the reaction solution is:

[0038] 1-3 parts of xylose, 1-3 parts of glucose, 0.5-2 parts of arginine, 0.5-2 parts of methionine, 0.5-2 parts of proline, 50-80 parts of water, 50-80 parts of soybean oil, among which The total mass of sugar is equal to the total mass of amino acids. After weighing and mixing the raw materials according to the formula, carry out Maillard reaction at a temperature of 100-150°C for 1-3 hours. After the reaction is completed, discard the water layer and collect the oil layer. is the reaction solution.

[0039] Preferably, the preparation method of the roasted potato leaching oil is:

[0040] Slice the potatoes, soak them in clean water for 10-30 minutes, wrap them in tin foil and put them in the oven at 180-250°C for 30-80 minutes, then take them out and soak the potato slices in soybean oil for 8-24 hours. Soybean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com