Novel MOFs (metal organic frameworks)-based composite supercapacitor electrode, and preparation and application of novel MOFs-based composite supercapacitor electrode

A composite electrode, a new type of technology, applied in the field of new MOFs-based composite supercapacitor electrodes and its preparation, can solve the problems of poor bonding force between MOFs and PANI, low electrochemical performance of supercapacitor electrodes, etc., and achieve good feasibility and low cost , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

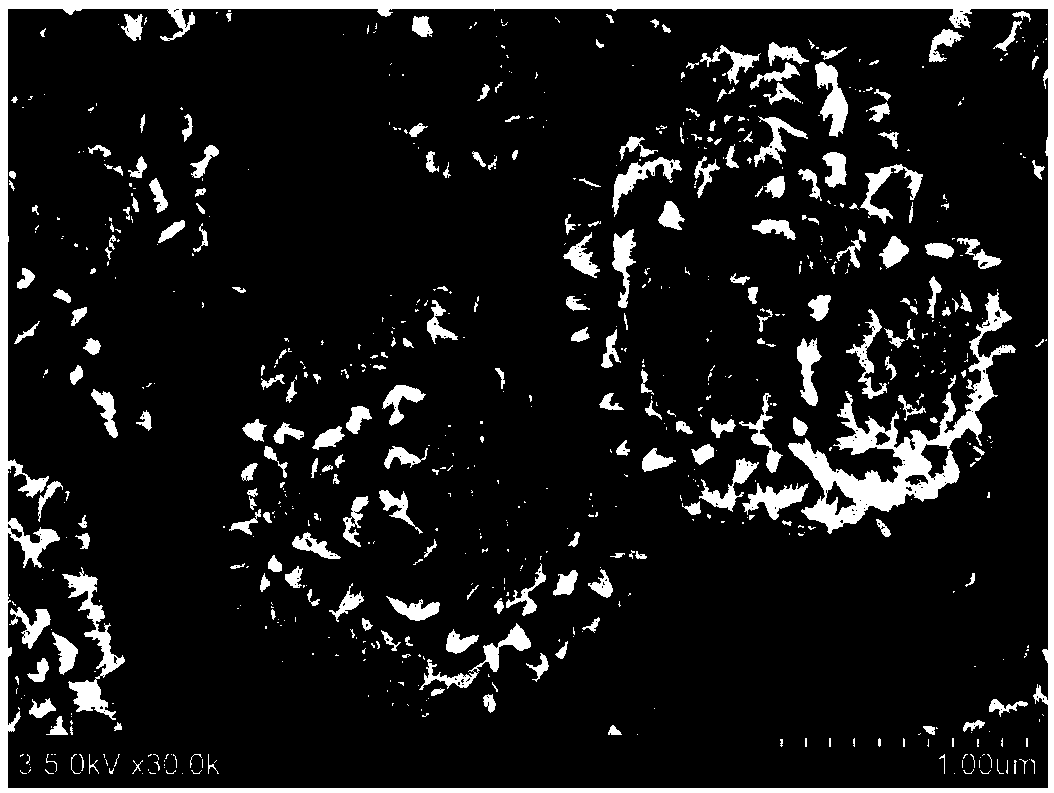

[0043] (1) Preparation of active MOFs substrate: Anhydrous zinc acetate, triazoledicarboxylic acid, and methanol were used as raw materials, and the molar ratio of anhydrous zinc acetate and triazoledicarboxylic acid was 1:4. Shake 280mg of anhydrous zinc acetate and 1108mg of triazoledicarboxylic acid in a beaker evenly, then add 80mL of methanol, stir mechanically for 5min, and react at room temperature for 24h to obtain a white suspension. Among them, the obtained active MOFs are polyhedral morphology with uniform size and complete structure, and the size is controlled at about 200nm.

[0044] (2) Prepolymerization of PANI: In the above white suspension, add 100uL aniline monomer and stir for 1h, cool the temperature to -5°C, then add 242mg dibenzoyl peroxide and 100uL 30% hydrogen peroxide, while keeping the temperature at Reaction at -5°C for 18h. After that, centrifuge at room temperature with a centrifugation speed of 5000 rpm and a centrifugation time of 3 minutes to ...

Embodiment 2

[0048] (1) Preparation of active MOFs substrates: using anhydrous zinc acetate, triazole dicarboxylic acid, 2-aminoterephthalic acid, and methanol as raw materials, wherein anhydrous zinc acetate, triazole dicarboxylic acid, 2-amino-p-phenylene The molar ratio of dicarboxylic acid is 1:2:1. Shake 372mg of anhydrous zinc acetate, 638mg of triazoledicarboxylic acid and 368mg of 2-aminoterephthalic acid in a beaker, then add 80mL of methanol, stir mechanically for 5min, and react at room temperature for 18h to obtain a white suspension. Among them, the obtained active MOFs are polyhedral morphology with uniform size and complete structure, and the size is controlled at about 500nm.

[0049] (2) Prepolymerization of PANI: In the above white suspension, add 100uL aniline monomer and stir for 1h, cool the temperature to -5°C, then add 363mg dibenzoyl peroxide and 50uL 30% hydrogen peroxide, while keeping the temperature at Reaction at -5°C for 18h. After that, centrifuge at room t...

Embodiment 3

[0054] (1) Preparation of active MOFs substrate: using anhydrous zinc acetate, triazole dicarboxylic acid, 5,10,15,20-tetrakis(4-carboxyphenyl)porphyrin, and methanol as raw materials, in which anhydrous zinc acetate The molar ratio of triazoledicarboxylic acid and 5,10,15,20-tetrakis(4-carboxyphenyl)porphyrin is 1:2:2. First dissolve 278mg of anhydrous zinc acetate in 40mL of methanol, then dissolve 478mg of triazoledicarboxylic acid and 2408mg of 5,10,15,20-tetrakis(4-carboxyphenyl)porphyrin in 40mL of methanol and then mix them mechanically Stir for 5 min, and react at room temperature for 20 h to obtain a white suspension. Among them, the obtained active MOFs are polyhedrons with uniform size and complete structure, and the size is controlled at about 1 μm.

[0055] (2) Prepolymerization of PANI: In the above white suspension, add 100uL aniline monomer and stir for 1h, cool the temperature to -5°C, then add 121mg dibenzoyl peroxide and 150uL 30% hydrogen peroxide, while k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrochemical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com