Overall processing and measuring device and method for wax model of intermediate casing

A measuring device and integral processing technology, applied in the direction of mechanical counter/curvature measurement, etc., to save production costs, shorten processing cycles, and avoid accumulated errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

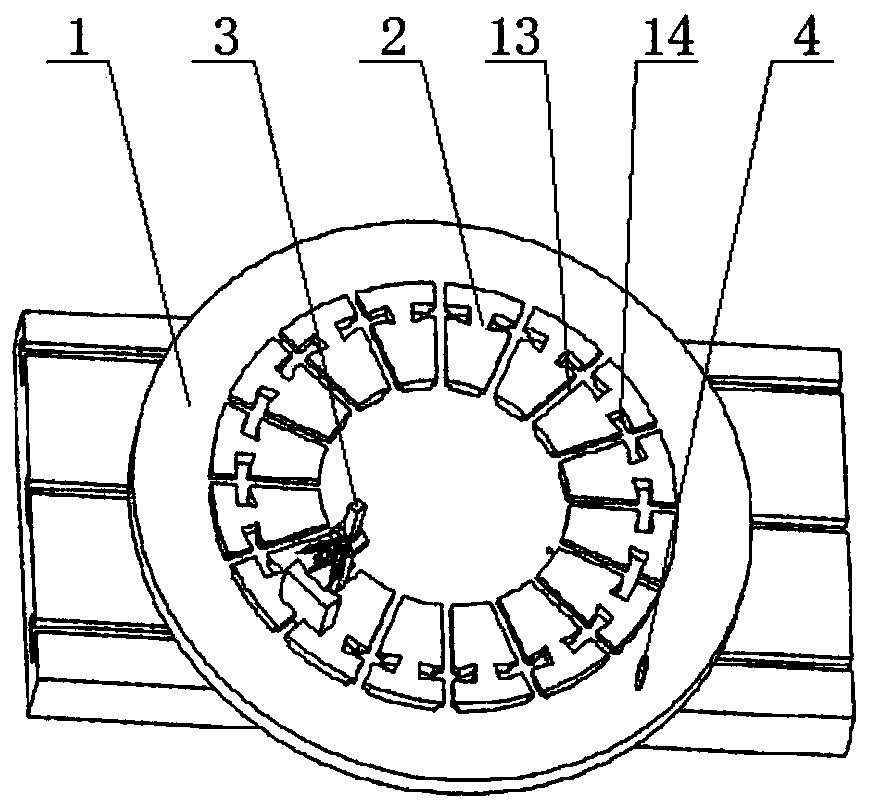

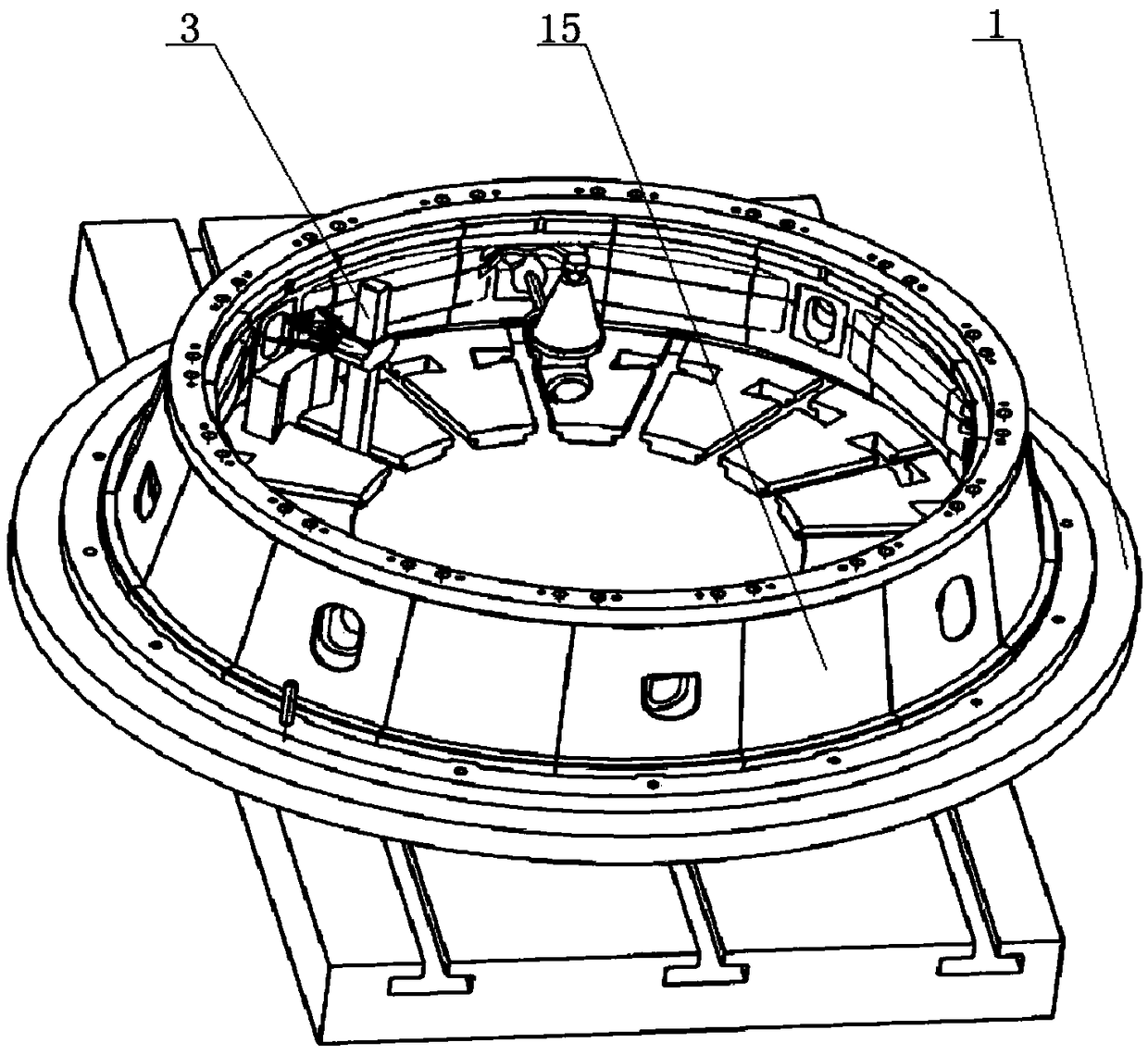

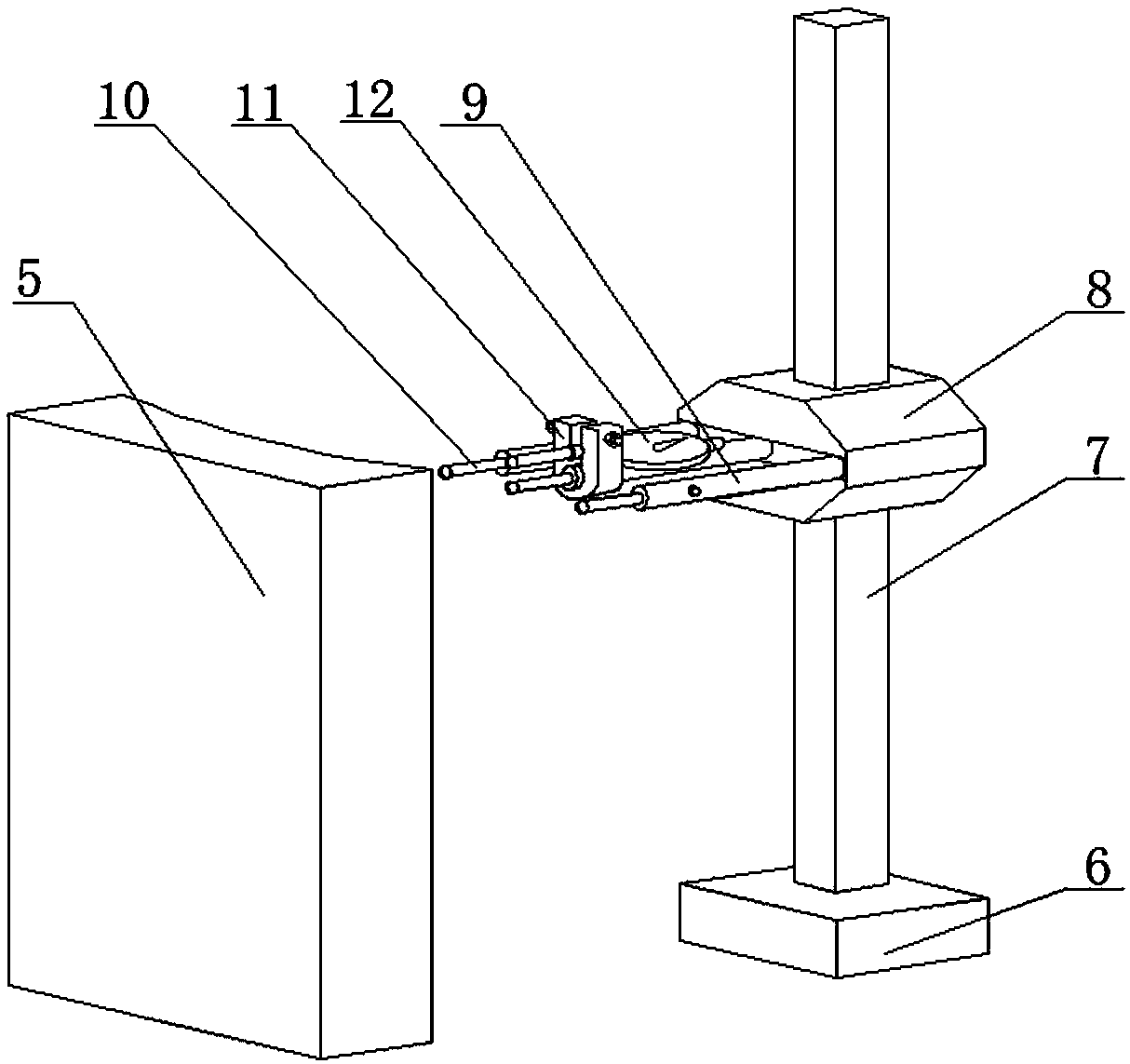

[0033] Such as Figure 1-Figure 4 As shown, an overall processing and measuring device for an intermediate casing wax model includes a clamp disc 1, and the upper surface of the clamp disc 1 is uniformly provided with sixteen circular shaft bosses 2, and the sixteen circular shaft bosses 2 form a circular shaft shape concentric with the fixture disk 1, a T-shaped slideway 13 is formed between two adjacent circular shaft bosses 2, and the outer edges of two adjacent circular shaft bosses 2 are formed on both sides of the T-shaped slideway 13 One side is provided with a gauge fixing groove 14, and the gauge fixing groove 14 is vertically arranged with the T-shaped slideway 13. The T-shaped slideway 13 is provided with a measuring device 3, and the clamp disc 1 and the ring-shaped integral casing wax The lower fixed plate 17 of mold 15 is fixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com