A kind of composite insulation board and preparation method thereof

A technology of composite thermal insulation and heat insulation layer, which is applied in thermal insulation, mechanical equipment, pipeline protection, etc. It can solve the problems of limited material application scenarios, reduced thermal insulation effect, narrow thermal insulation interval, etc., and achieves light and thin thickness and reduced packaging Scale, the effect of small changes in ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

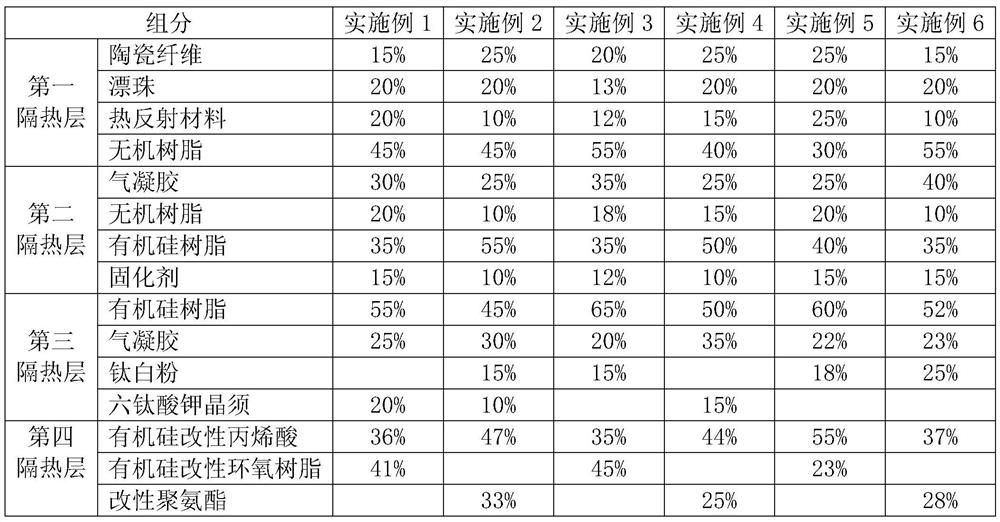

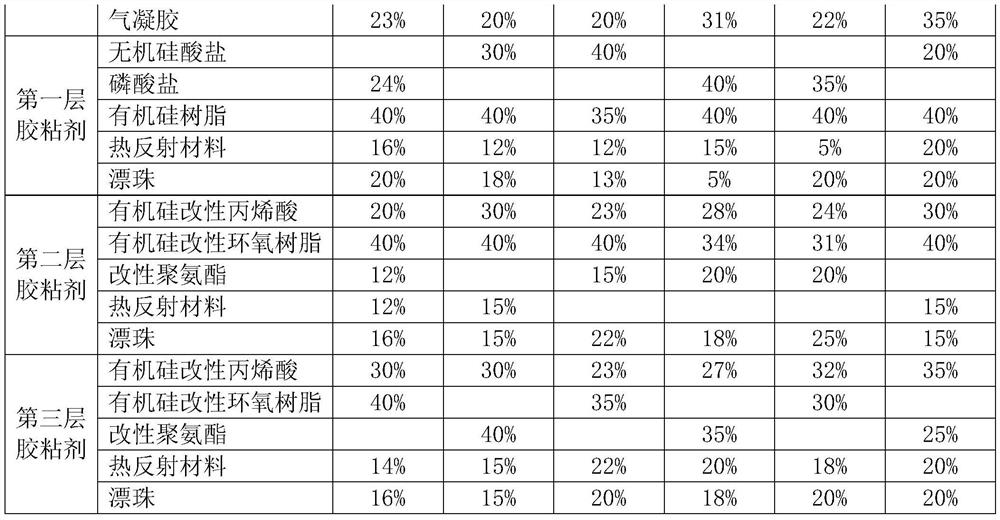

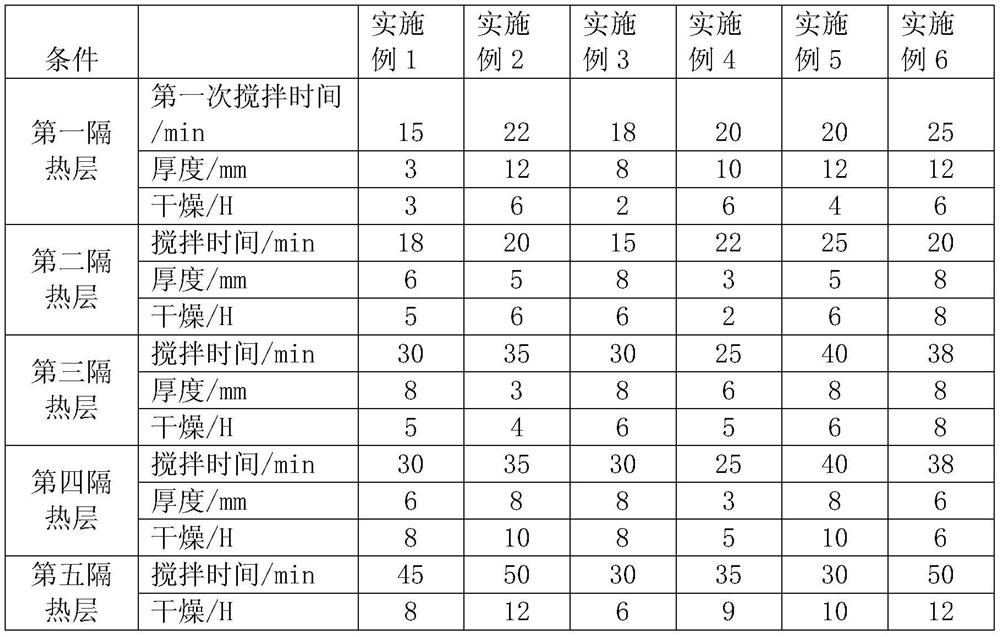

[0025] Below in conjunction with specific embodiment 1-6, the present invention will be further described:

[0026] A preparation method of a composite insulation board, comprising the steps of:

[0027] 1) Mix inorganic silicates or phosphates, silicone resins, heat-reflecting materials, and floating beads according to the ratio and mix thoroughly for 15 minutes to prepare the first layer of adhesive;

[0028] 2) Lay the substrate on the bottom of the prefabricated mold, mix and stir the ceramic fiber, floating beads, heat reflective material, and inorganic resin for 25 minutes, and lay it on the substrate at the bottom of the prefabricated mold with a thickness of 8-25mm and a relative humidity of 45%. Dry for 1 to 3 hours to obtain the first heat insulation layer;

[0029] 3) Coat the first layer of adhesive on the first heat insulation layer with a thickness of 3-5 mm, then mix and stir the airgel, inorganic resin, silicone resin, and curing agent in proportion to prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com