Prefabricated pipe rack push construction device

A construction device and pipe gallery technology, which is applied in the field of prefabricated pipe gallery pushing construction devices, can solve problems such as slow construction speed, construction technical requirements, and high project cost, and achieve the effects of simple structure, saving labor and construction time, and speeding up the construction pace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] In this embodiment, the specific process of using the prefabricated pipe gallery to push the construction device for construction is as follows:

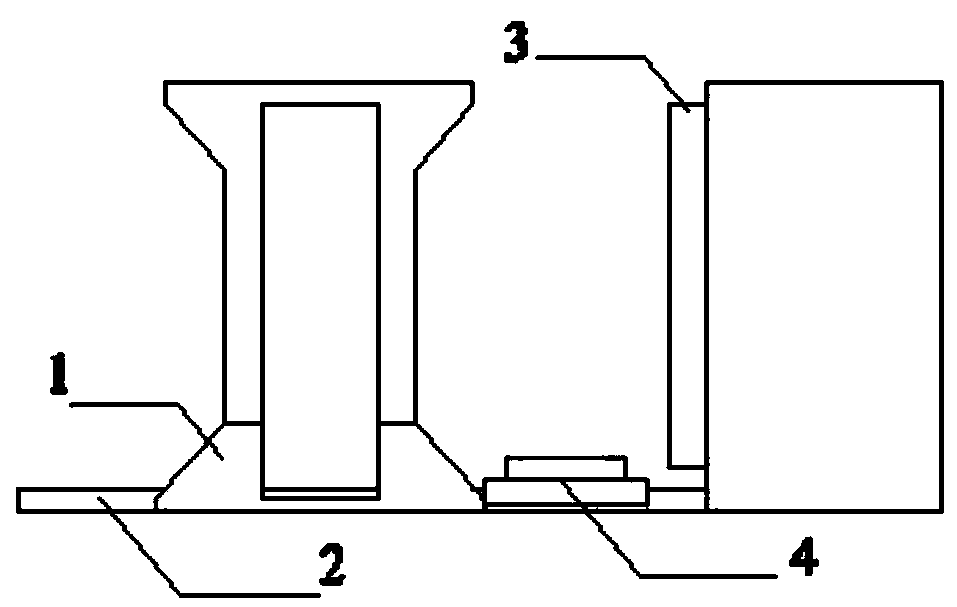

[0018] (1) After successful digging by shield machine or manual digging method, track 2 is paved;

[0019] (2) Lift the existing prefabricated pipe gallery pusher, put it on the pre-paved track 2 and install and fix it;

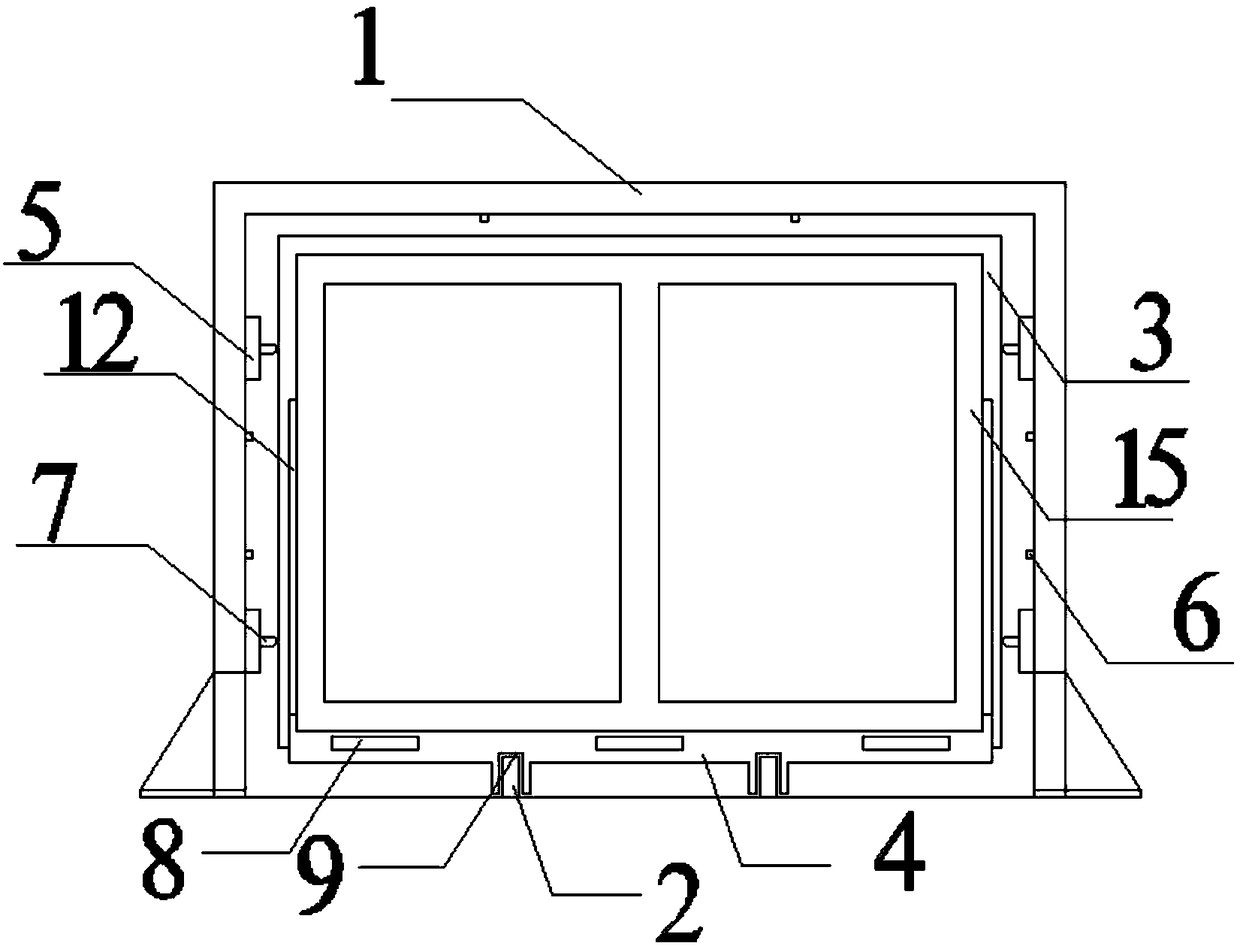

[0020] (3) The worker puts the auxiliary tool 4 on the track 2 of the pusher trough (it can be moved directly because it is a light-weight and high-strength material), and then one or two cranes place the formed prefabricated pipe gallery 15 on the auxiliary Tool 4 (the prefabricated pipe gallery and auxiliary tools are matched), or complete the assembly of the prefabricated pipe gallery on auxiliary tool 4;

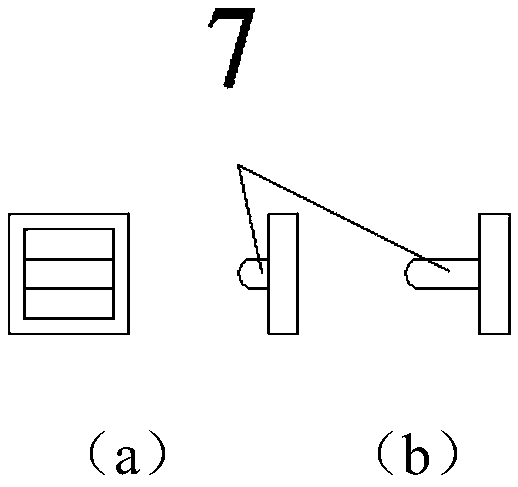

[0021] (4) Use the pressure device 3 to push the auxiliary tool 4 and the prefabricated pipe gallery on it to the fixed frame 1, and use the laser displacement meter 6 and the correction device 5 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com