Culture medium used for microorganism solid flux fermentation and preparation method and application thereof

A culture medium and microorganism technology, which is applied to the medium and preparation field of microbial solid-state flux fermentation, can solve the problems of small loading, affecting the use efficiency of a solid-state flux culture device, affecting the application efficiency of a solid-state flux culture device, and the like, Achieve easy molding, improve high-throughput screening efficiency, and reduce the risk of bacterial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0036] The culture media used for microbial solid-state flux fermentation in Examples 1 to 5 are all disc-shaped, and the components of the culture media and the weight percentages of each component in the culture media are shown in Table 1. Among them, the fineness of bran, soybean meal and wheat is 40-80 mesh, and the fineness of cornstarch and maltodextrin powder is more than 80 mesh; the quality of each medium is 0.4-0.9g, and the diameter of the medium is 6-15mm, and the thickness of the culture medium is 5-10mm.

[0037] Embodiments 1-5 are used for the preparation method of the culture medium of microbial solid-state flux fermentation as follows:

[0038] (1) Dry each component in the culture medium until the water content in each component is not higher than 10%; at the same time, grind the bran, soybean meal and wheat to a fineness of 40-80 mesh, cornstarch and malt The dextrin powder is pulverized to a fineness of more than 80 mesh.

[0039] (2) Weighing each compo...

Embodiment 6

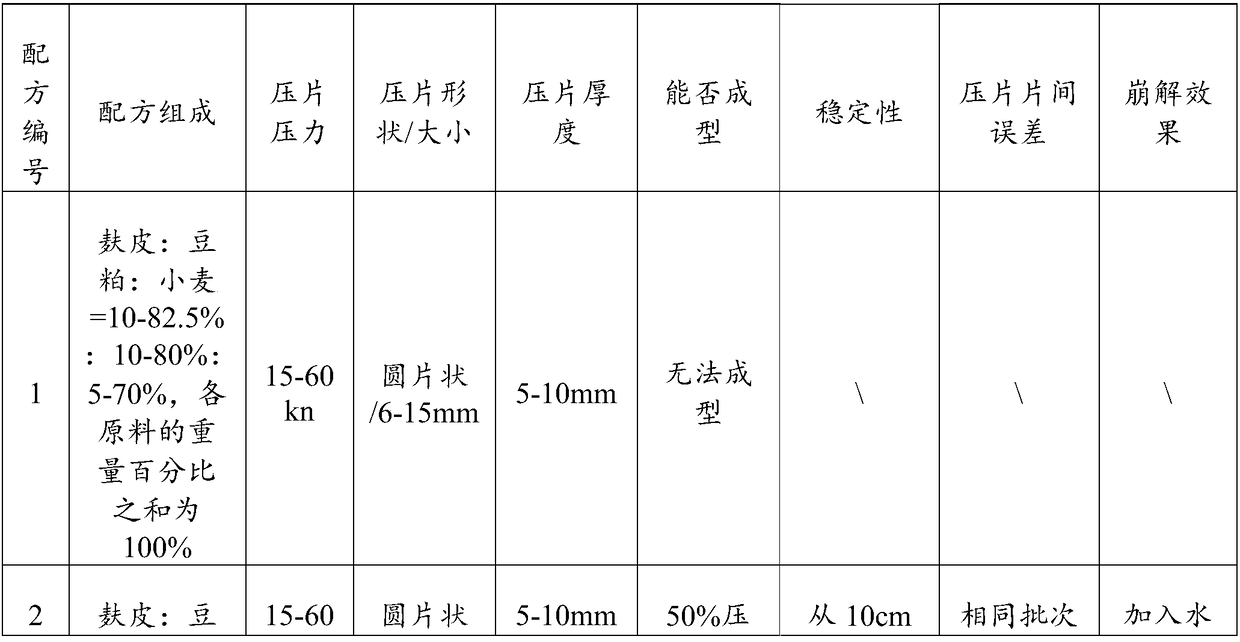

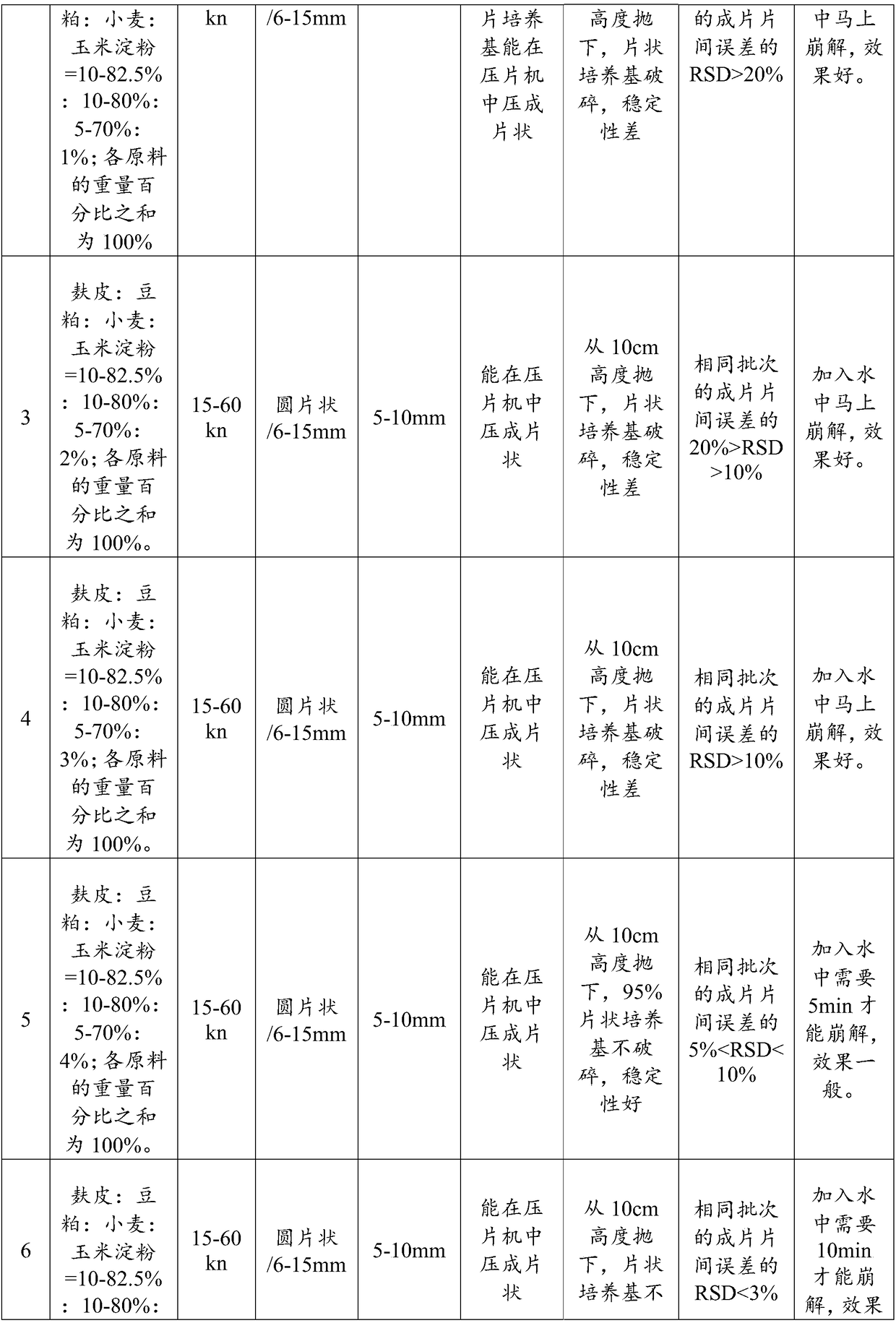

[0043] The impact of different raw material ratios of embodiment 6 on the culture medium becoming sheet

[0044] In this example, according to the preparation method of the culture medium in Examples 1-5, the culture medium was prepared by using different ratios of raw materials, and the influence of the ratio of raw materials on the formation of the culture medium was compared. The results are shown in Table 2.

[0045] From formula No. 1 in Table 2, it can be seen that using bran, soybean meal, and wheat alone as raw materials for medium tableting cannot be formed, so it is necessary to add a certain filler to assist in forming. However, in order not to affect the effect of the filler on the components of the solid-state fermentation medium, corn starch is selected as the preferred filler. However, as can be seen from the analysis results of No. 2-6 medium from the back, adding 1% cornstarch can improve the tableting of the medium, but 50% of the tableting medium cannot be m...

Embodiment 7

[0051] The application of embodiment 7 substratum of the present invention in Aspergillus oryzae

[0052] 1. Porous fermentation device

[0053] Refer to the solid-state flux culture device described in the patent CN 107446804A.

[0054] 2. Experimental materials and methods

[0055] 2.1. Culture medium composition and production method

[0056] The composition of medium 1 is composed of the following raw materials by weight percentage: 23% of bran; 56% of soybean meal; 21% of wheat.

[0057] The medium 2 is composed of the following raw materials by weight percentage: bran 25%; soybean meal 55%; wheat 20%.

[0058] The composition of medium 3 is composed of the following raw materials by weight percentage: 22% of bran; 58% of soybean meal; 20% of wheat.

[0059] The composition of medium 4 is composed of the following raw materials by weight percentage: 22% of bran; 55% of soybean meal; 23% of wheat.

[0060] The medium 5 is composed of the following raw materials by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com