Circulation box used for machining circulation of engine blade

A technology for engine blades and turnover boxes, which is applied to machine containers, containers for preventing mechanical damage, and assembly machines, etc. It can solve problems such as blade scratches, collisions or flying out, and production inconvenience, so as to reduce weight and absorb vibrations Effects of energy and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, design of the present invention is further elaborated:

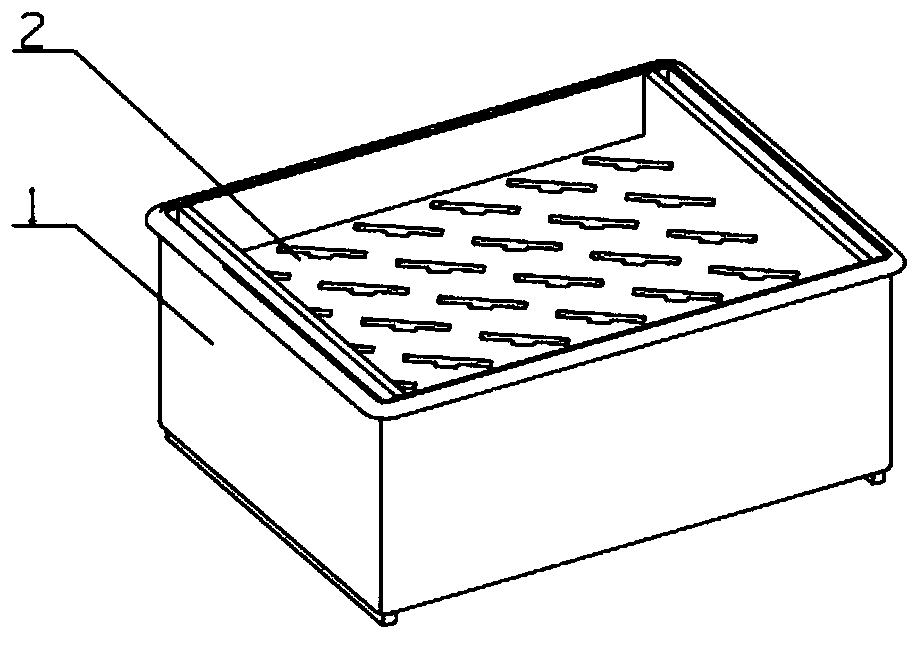

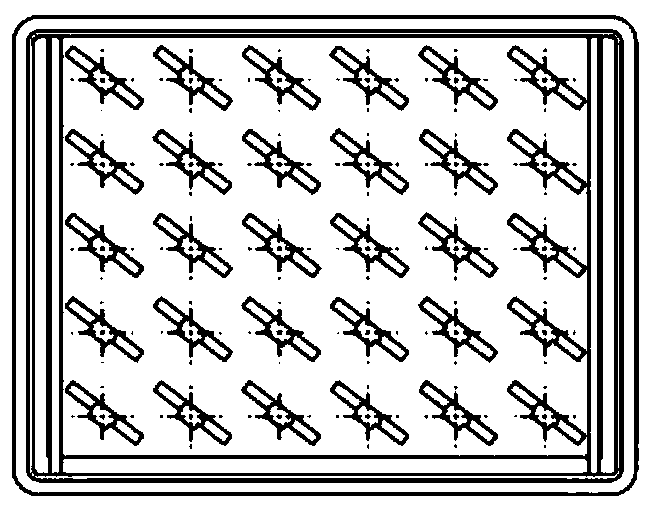

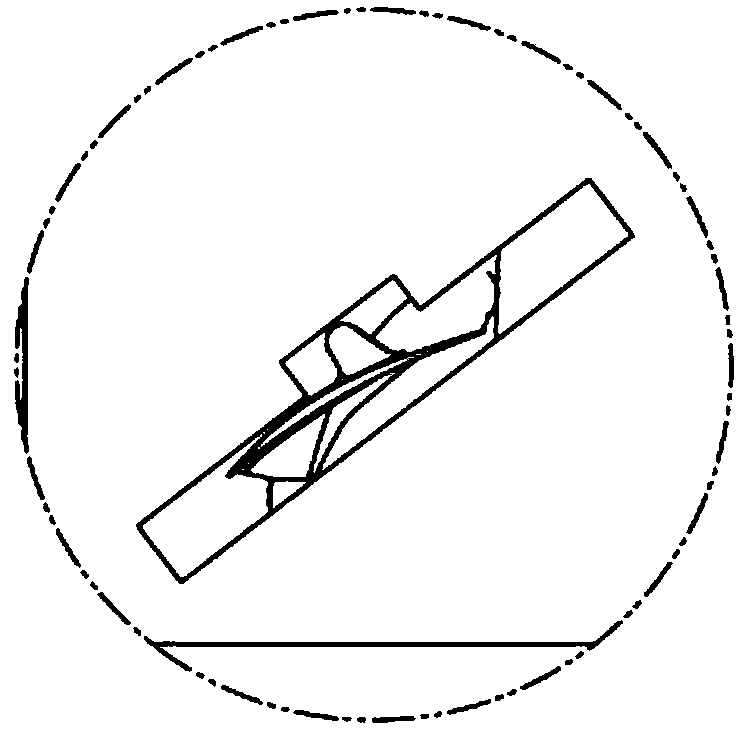

[0018] like figure 1 As shown, a whole piece of EPE anti-seismic pearl cotton is used as the filling material 2 and embedded in the box 1 made of high-density polyethylene. This combination reduces the weight of the turnover box to a certain extent. The distance is good for ventilation; the pearl cotton has double rectangular slots (one long rectangular slot and one short rectangular slot) in the matrix array in the length and width directions. The utilization rate of the body placement slot (the density of the blade body slot per unit volume), the bottom of the box corresponding to the bottom of the pearl cotton through hole has a circular hole such as figure 2 As shown, the structure forms a ventilated and convective environment, which has a certain weak corrosion and weak oxidation protection effect on the blade turnover; the rectangular groove opened on the pea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com