Melamine foam uniform foaming device

A foaming device, melamine technology, applied in the field of melamine foam uniformity foaming device, can solve problems such as poor foaming uniformity of melamine foam, achieve good adjustability and controllability, safe use, and good coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] like figure 1 , figure 2 As shown, the present embodiment provides a melamine foam uniformity foaming device, comprising a body of furnace 1 and multiple groups of microwave devices, and the front and rear side walls of the body of furnace 1 are respectively provided with a feed door 7 and a discharge door, each group The microwave device includes a microwave source 2 and a waveguide 3. The microwave source 2 is a split-type multi-unit magnetron combined microwave source 2 with a total power of 16-30 kilowatts. The operating frequency of each unit magnetron is 915 MHz.

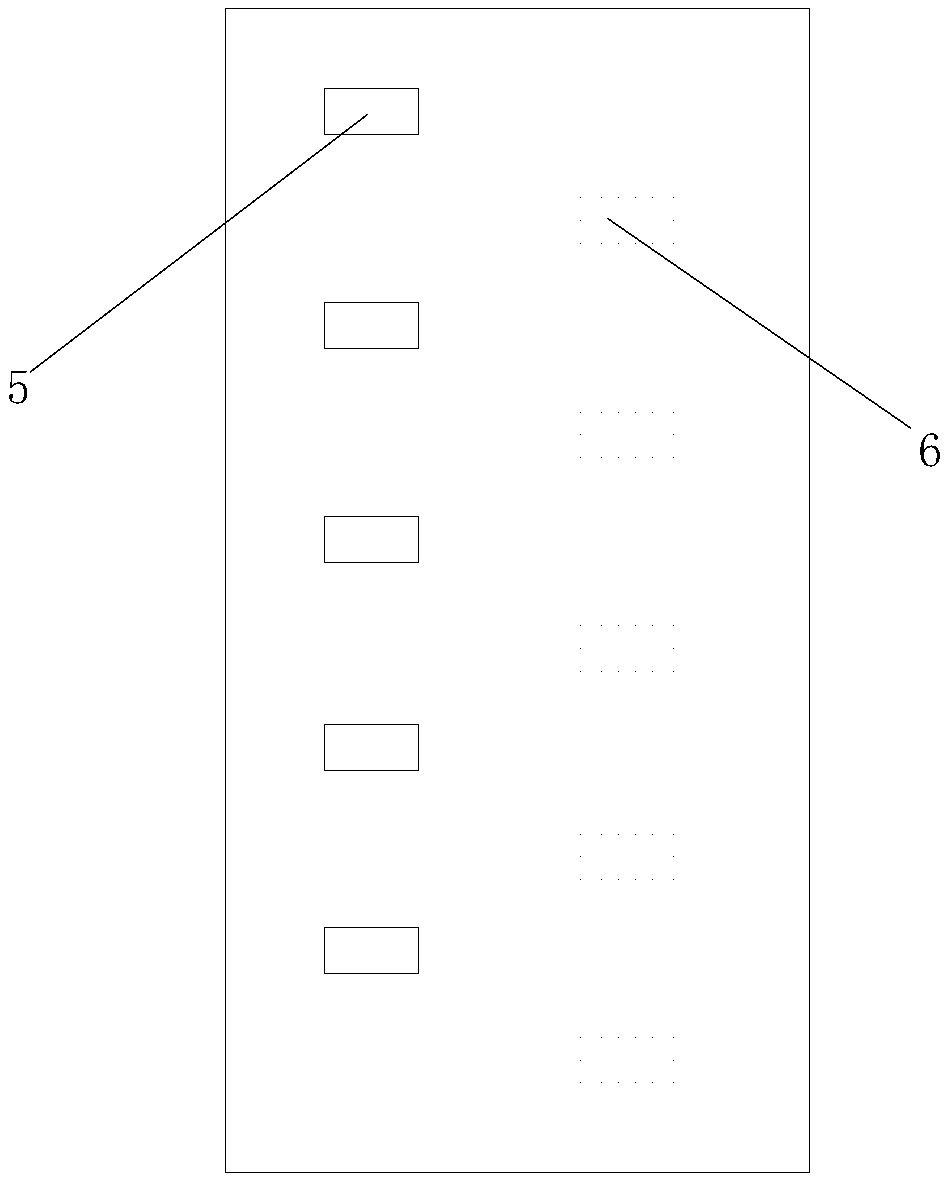

[0025] The microwave source 2 is arranged at one end of the waveguide 3, and the waveguide 3 is divided into a first branch pipe 3-1 and a second branch pipe 3-2 by a power divider 4, and the first branch pipe 3-1 is arranged in the furnace On the top wall of the furnace body 1, the second branch pipe 3-2 is arranged outside the bottom wall of the furnace body 1, and the top microwave feeding port 5 i...

Embodiment 2

[0029] like figure 1 , image 3 As shown, this embodiment provides a melamine foam uniformity foaming device.

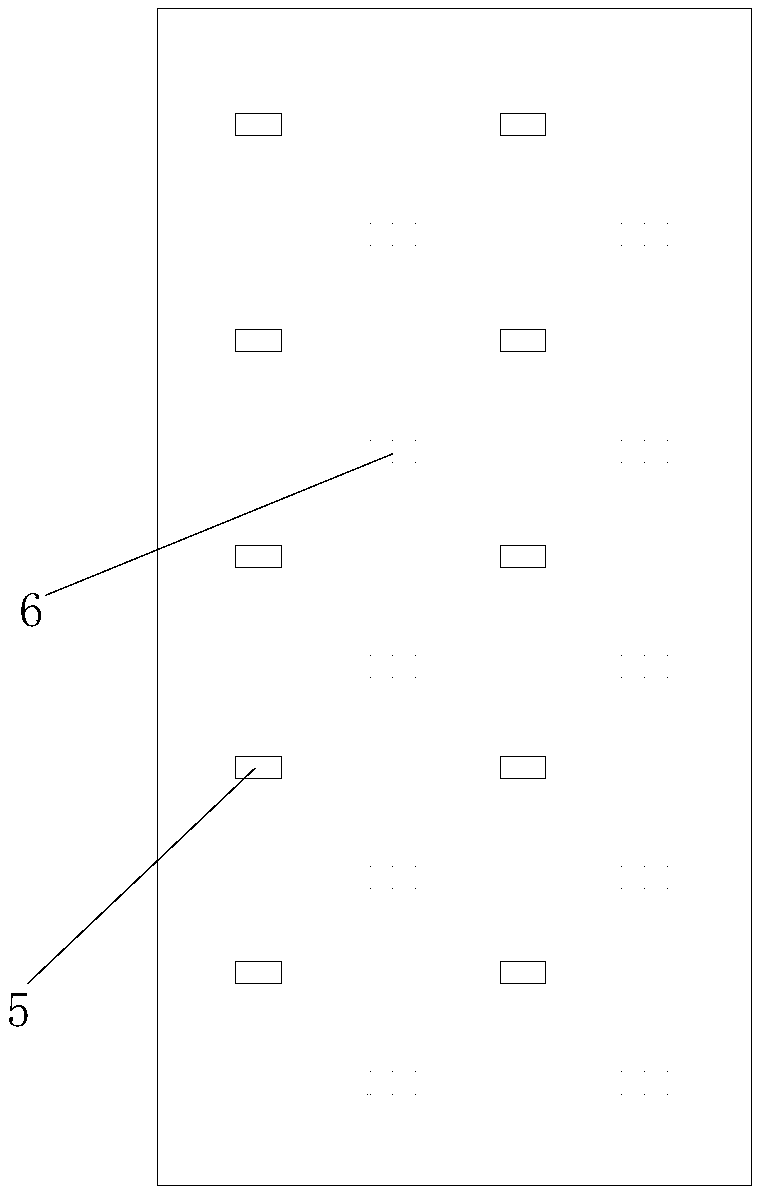

[0030] Among them, there are 2 top microwave feed ports 5 arranged on each group of first branch pipes 3-1, and 2 bottom microwave feed ports 6 arranged on each group of second branch pipes 3-2, adjacent to each other. The distance between the top microwave feed port 5 and the bottom microwave feed port 6 along the width direction of the furnace body 1 is 120mm. The schematic diagram of the microwave feed port distribution is shown in image 3 As shown, the dotted line in the figure indicates the microwave feed port on the bottom wall.

[0031] Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com