High-speed train grinding wheel and preparation method thereof

A grinding wheel and high-speed iron technology, which is applied in the direction of grinding/polishing equipment, grinding devices, manufacturing tools, etc., can solve the problems of service life, processing efficiency and poor yield of electroplated grinding wheels, and achieve low cost, improved service life, and good quality. The effect of holding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

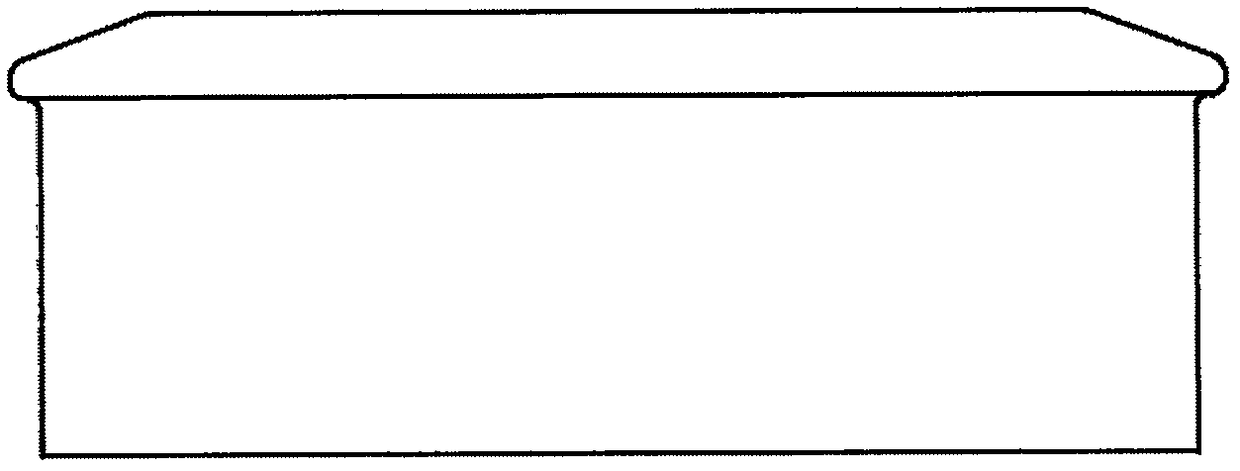

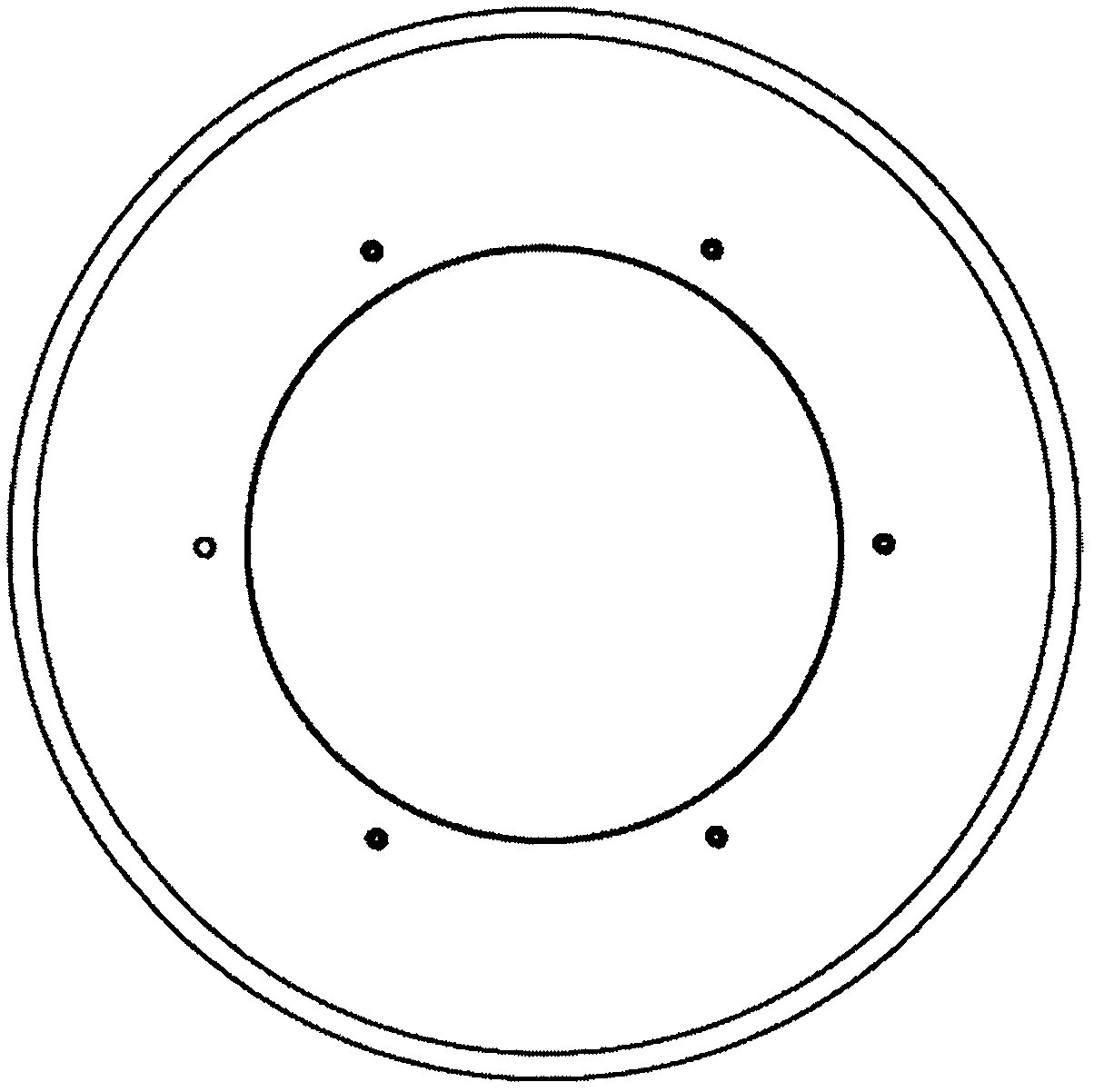

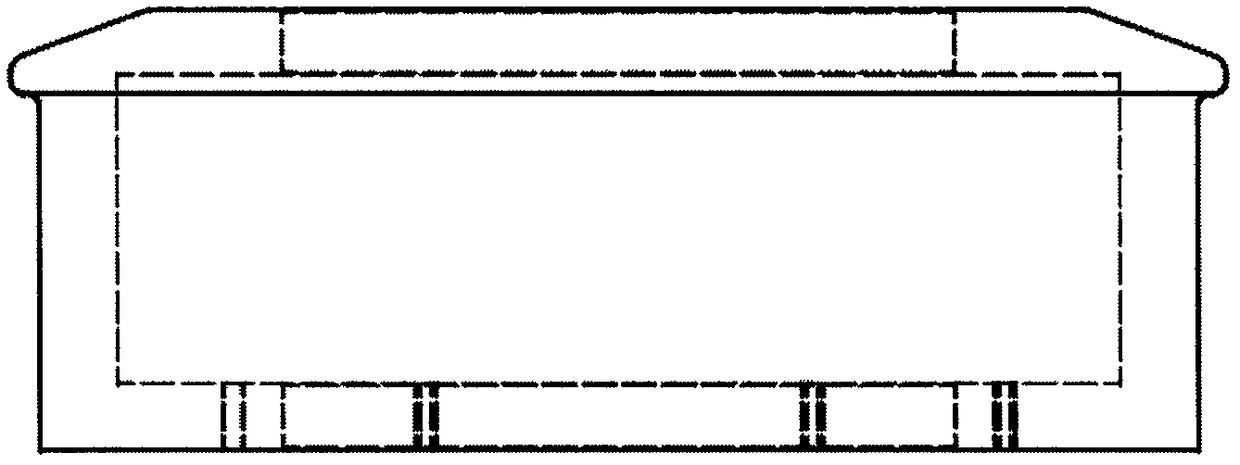

Image

Examples

Embodiment 1

[0034]This embodiment provides a method for preparing a high-speed iron grinding wheel. Including the following process steps:

[0035] 1) Ingredients: Pre-mix the graded diamond particles and silicon carbide particles with the alloy powder solder to make a molding material. The mixing time is 50 minutes using a three-dimensional mixing machine. The composition of alloy powder solder is 31wt% Ni, 25wt% Mn, 1.8wt% Si, 0.80wt% B, 1.0wt% Fe, 2.5wt% Cr, and the balance is Cu; the added diamond particles The weight is 3.2wt% of the weight of the alloy powder solder, and the weight of the added silicon carbide particles is 0.40wt% of the weight of the alloy powder solder.

[0036] 2) Cloth: Adjust the tooling mold, place the 65Mn steel substrate formed by machining (after cleaning the surface of the steel substrate, pre-coated with adhesive and flow blocking agent), then put the molding material and assemble it into the forming fixture. The steel substrate is 65Mn Material.

[00...

Embodiment 2

[0043] This embodiment provides a method for preparing a high-speed iron grinding wheel. Including the following process steps:

[0044] 1) Ingredients: Pre-mix the graded diamond particles and silicon carbide particles with the alloy powder solder to make a molding material. The mixing time is 50 minutes using a three-dimensional mixing machine. The composition of alloy powder solder is 35wt% Ni, 23wt% Mn, 2.0wt% Si, 0.80wt% B, 1.2wt% Fe, 3.2wt% Cr, and the balance is Cu; the added diamond particles The weight is 2.5wt% of the weight of the alloy powder solder, and the weight of the added silicon carbide particles is 0.5wt% of the weight of the alloy powder solder.

[0045] 2) Cloth: Adjust the tooling mold, place the 65Mn steel substrate formed by machining (after cleaning the surface of the steel substrate, pre-coated with adhesive and flow blocking agent), then put the molding material and assemble it into the forming fixture. The steel substrate is 65Mn Material.

[00...

Embodiment 3

[0052] This embodiment provides a method for preparing a high-speed iron grinding wheel. Including the following process steps:

[0053] 1) Ingredients: Pre-mix the graded diamond particles and silicon carbide particles with the alloy powder solder to make a molding material. The mixing time is 50 minutes using a three-dimensional mixing machine. The composition of alloy powder solder is 35wt% Ni, 24wt% Mn, 1.25wt% Si, 1.0wt% B, 1.5wt% Fe, 1.2wt% Cr, and the balance is Cu; the added diamond particles The weight is 3.0wt% of the weight of the alloy powder solder, and the weight of the added silicon carbide particles is 0.3wt% of the weight of the alloy powder solder.

[0054] 2) Cloth: Adjust the tooling mold, place the 65Mn steel substrate formed by machining (after cleaning the surface of the steel substrate, pre-coated with adhesive and flow blocking agent), then put the molding material and assemble it into the forming fixture. The steel substrate is 65Mn Material.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com