A universal approach to effectively enhance the catalytic performance of perovskite catalysts

A technology of catalytic performance and perovskite, applied in the field of effectively improving the catalytic performance of perovskite catalysts, can solve the problems of low catalyst stability, complex process, high cost, and ensure oxygen evolution performance, good universality, and adsorption. The ability to moderate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

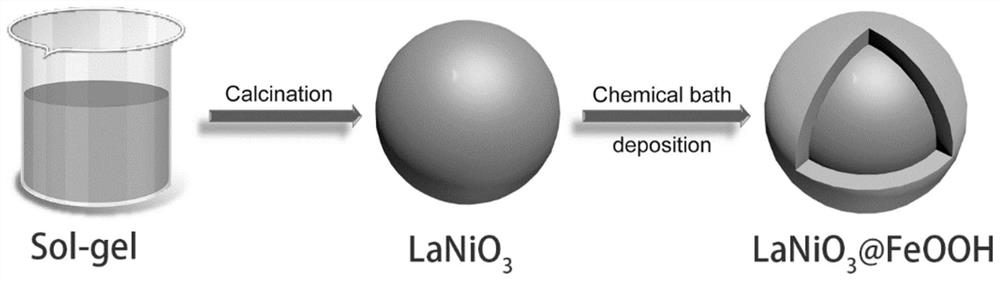

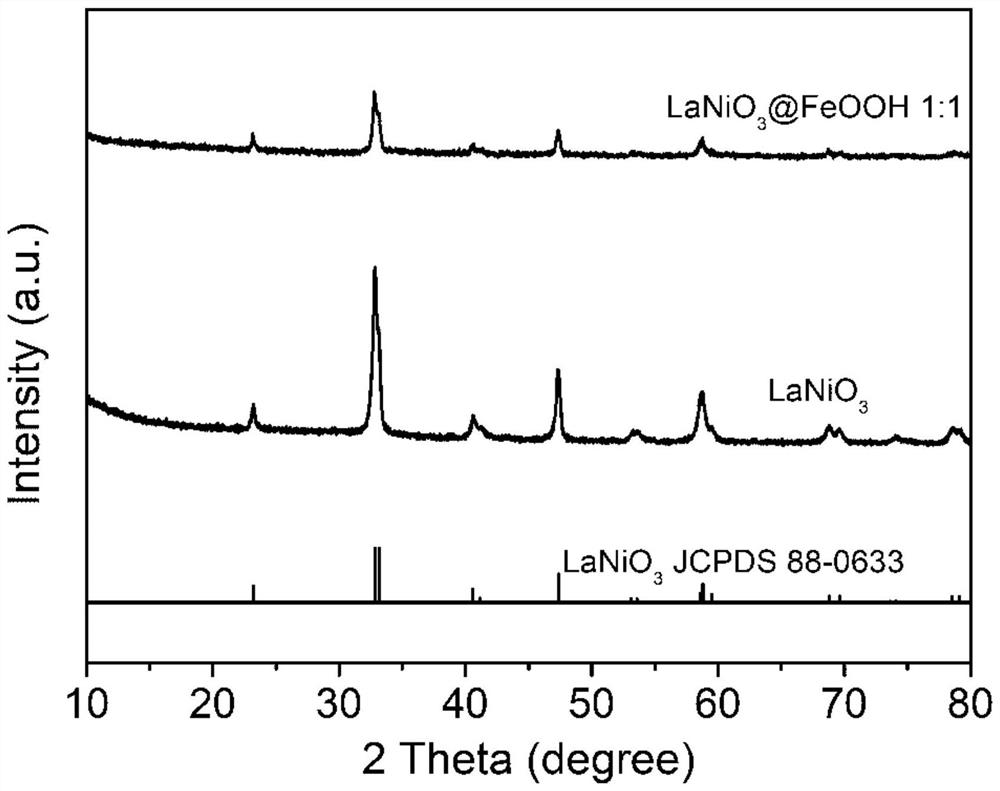

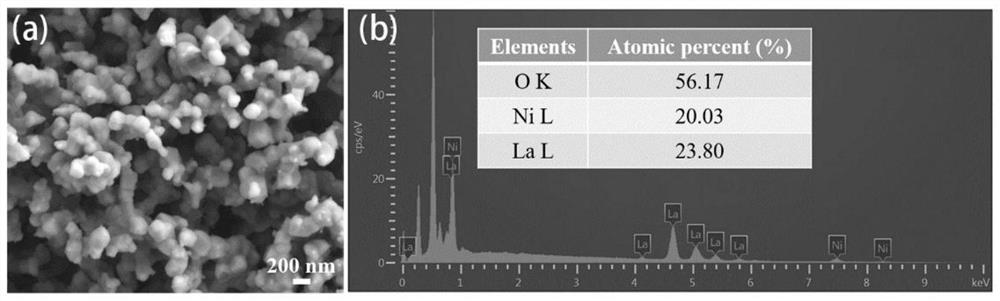

[0038] A universal approach to effectively enhance the catalytic performance of perovskite catalysts, such as figure 1 shown, including:

[0039] (1) Prepare the perovskite oxide precursor by sol-gel method, weigh 0.02mol of ethylenediaminetetraacetic acid and dissolve it in 100ml of deionized water, stir until dissolved; then add 20ml of ammonia water (25-28%) , stirred for 5 minutes; then weighed 0.01mol of lanthanum nitrate and 0.01mol of nickel nitrate and added to the above-mentioned ethylenediaminetetraacetic acid-ammonia solution, after the lanthanum nitrate and nickel nitrate were dissolved, added 0.04mol of citric acid to adjust the pH of the solution to 8 ; The ratio of the amount of target metal element, ethylenediaminetetraacetic acid and acidic substance is 1:1:2;

[0040] (2) Place the solution in step (1) in an oil bath, heat and stir at 100° C. for about 4 hours with a magnetic heating stirrer to form a blue viscous gel;

[0041] (3) Put the gel obtained in s...

Embodiment 2

[0052] A universal method to effectively improve the catalytic performance of perovskite catalysts, including:

[0053] (1) Prepare the perovskite oxide precursor by sol-gel method, weigh 0.02mol of ethylenediaminetetraacetic acid and dissolve it in 100ml of deionized water, stir until dissolved; then add 20ml of ammonia water (25-28%) , stirred for 5 minutes; then weighed 0.01mol of lanthanum nitrate and 0.01mol of nickel nitrate and added to the above-mentioned ethylenediaminetetraacetic acid-ammonia solution, after the lanthanum nitrate and nickel nitrate were dissolved, added 0.04mol of citric acid to adjust the pH of the solution to 8 ;

[0054] (2) Place the solution in step (1) in an oil bath, heat and stir at 100° C. for about 4 hours with a magnetic heating stirrer to form a blue viscous gel;

[0055] (3) Put the gel obtained in step (2) in a crucible, first calcined at 250°C for 5 hours at a low temperature to remove organic complexes, and the heating rate was 2°C / m...

Embodiment 3

[0058] A universal method to effectively improve the catalytic performance of perovskite catalysts, including:

[0059] (1) Prepare the perovskite oxide precursor by sol-gel method, weigh 0.02mol of ethylenediaminetetraacetic acid and dissolve it in 100ml of deionized water, stir until dissolved; then add 20ml of ammonia water (25-28%) , stirred for 5 minutes; then weighed 0.01mol of lanthanum nitrate and 0.01mol of nickel nitrate and added to the above-mentioned ethylenediaminetetraacetic acid-ammonia solution, after the lanthanum nitrate and nickel nitrate were dissolved, added 0.04mol of citric acid to adjust the pH of the solution to 8 ;

[0060] (2) Place the solution in step (1) in an oil bath, heat and stir at 100° C. for about 4 hours with a magnetic heating stirrer to form a blue viscous gel;

[0061] (3) Put the gel obtained in step (2) in a crucible, first calcined at 250°C for 5 hours at a low temperature to remove organic complexes, and the heating rate was 2°C / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com