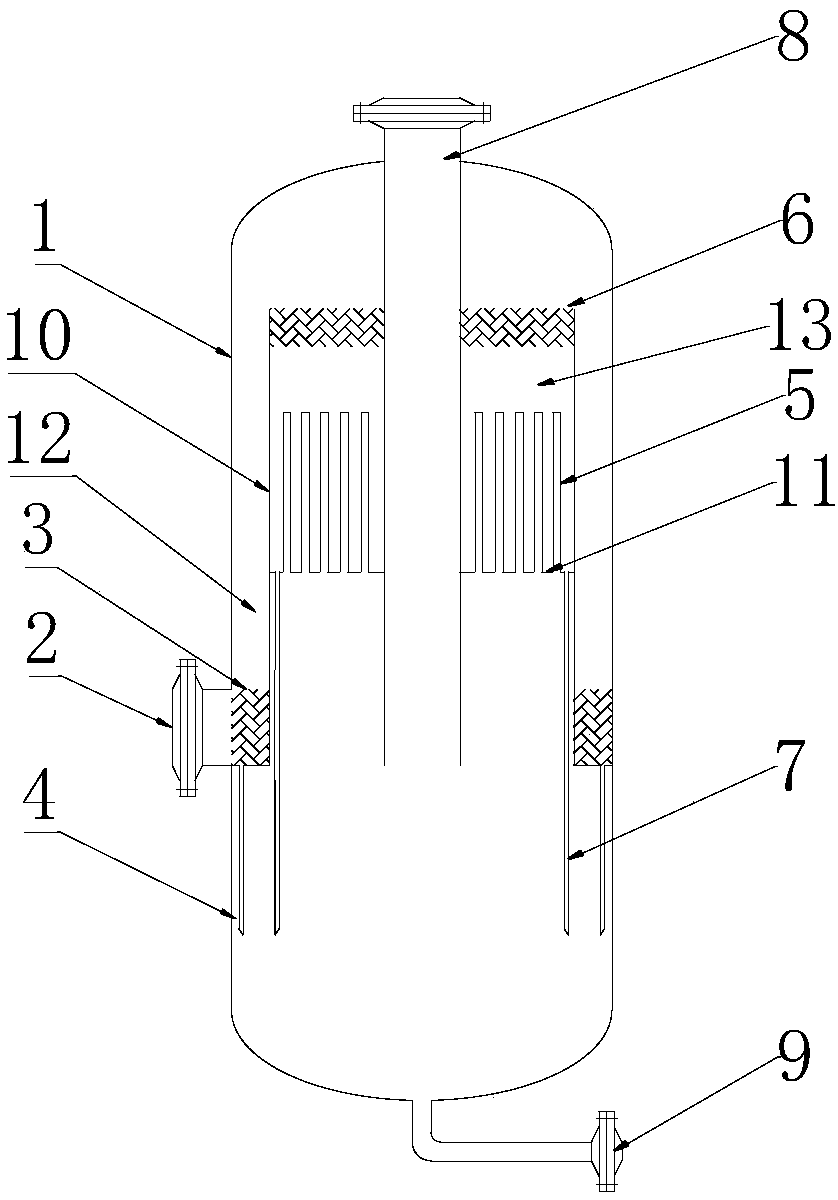

Methanol wax removal film separator and method for methanol wax removal

A separator and methanol technology, applied in semipermeable membrane separation, chemical instruments and methods, separation/purification of hydroxyl compounds, etc., can solve problems such as high operating costs, high filter membrane prices, clogged heat exchangers, etc., and achieve improvement Methanol quality, simple membrane making process, and the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A set of polarized electrodes were respectively placed on three sets of parallel faces of the cube glass vessel, and an aqueous solution of polyacrylic acid (number average molecular weight: 2000) with a concentration of 12 wt% was placed in the cube glass vessel. (1) Add 1,3-propanediol relative to polyacrylic acid 10wt% to the polyacrylic acid aqueous solution in the form of a 12wt% aqueous solution, stir for 5 minutes, and then turn on the first set of polarized electrodes with a boosting rate of 5V / min , boosted to 200V, and then kept for 30min to complete a polarization cycle; (2) 1,3-propanediol relative to polyacrylic acid 10wt% was added to the polyacrylic acid aqueous solution in the form of a 12wt% aqueous solution, and stirred for 5min, Then turn on the second group of polarized electrodes, the boost rate is 5V / min, boost to 200V, and then keep for 30min to complete the second polarization cycle; (3) the 1,3-propanediol , in the form of a 12wt% aqueous soluti...

Embodiment 2

[0039] A set of polarized electrodes were respectively placed on three sets of parallel surfaces of the cube glass vessel, and an aqueous solution of polyacrylic acid (number average molecular weight: 1000) with a concentration of 16 wt% was placed in the cube glass vessel. (1) Add 1,3-propanediol relative to polyacrylic acid 5wt%, in the form of a 16wt% aqueous solution to the polyacrylic acid aqueous solution, stir for 10 minutes, and then turn on the first set of polarized electrodes, and the boost rate is 1V / min , boosted to 300V, and then kept for 50min to complete a polarization cycle; (2) 1,3-propanediol relative to polyacrylic acid 5wt% was added to the polyacrylic acid aqueous solution in the form of a 16wt% aqueous solution, and stirred for 10min, Then turn on the second group of polarized electrodes, the boost rate is 1V / min, boost to 300V, and then keep for 50min to complete the second polarization cycle; (3) the 1,3-propanediol , in the form of a 16wt% aqueous sol...

Embodiment 3

[0043] A set of polarized electrodes were respectively placed on three sets of parallel surfaces of the cube glass vessel, and an aqueous solution of polyacrylic acid (number average molecular weight: 2500) with a concentration of 14 wt% was placed in the cube glass vessel. (1) Add 1,3-propanediol relative to polyacrylic acid 7wt% to the polyacrylic acid aqueous solution in the form of a 14wt% aqueous solution, stir for 3 minutes, and then turn on the first set of polarized electrodes with a boosting rate of 10V / min , boosted to 260V, and then kept for 30min to complete a polarization cycle; (2) 1,3-propanediol relative to polyacrylic acid 7wt% was added to the polyacrylic acid aqueous solution in the form of a 14wt% aqueous solution, and stirred for 3min, Then turn on the second group of polarized electrodes, the boost rate is 10V / min, boost to 260V, and then keep it for 30min to complete the second polarization cycle; (3) the 1,3-propanediol , in the form of a 14wt% aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com