Actuator control system and method based on deep learning and deep neural network

A deep neural network and control system technology, applied in the field of steering gear control system based on deep learning and deep neural network, can solve problems such as abnormal jitter and steady-state error increase, and achieve the effect of solving unstable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

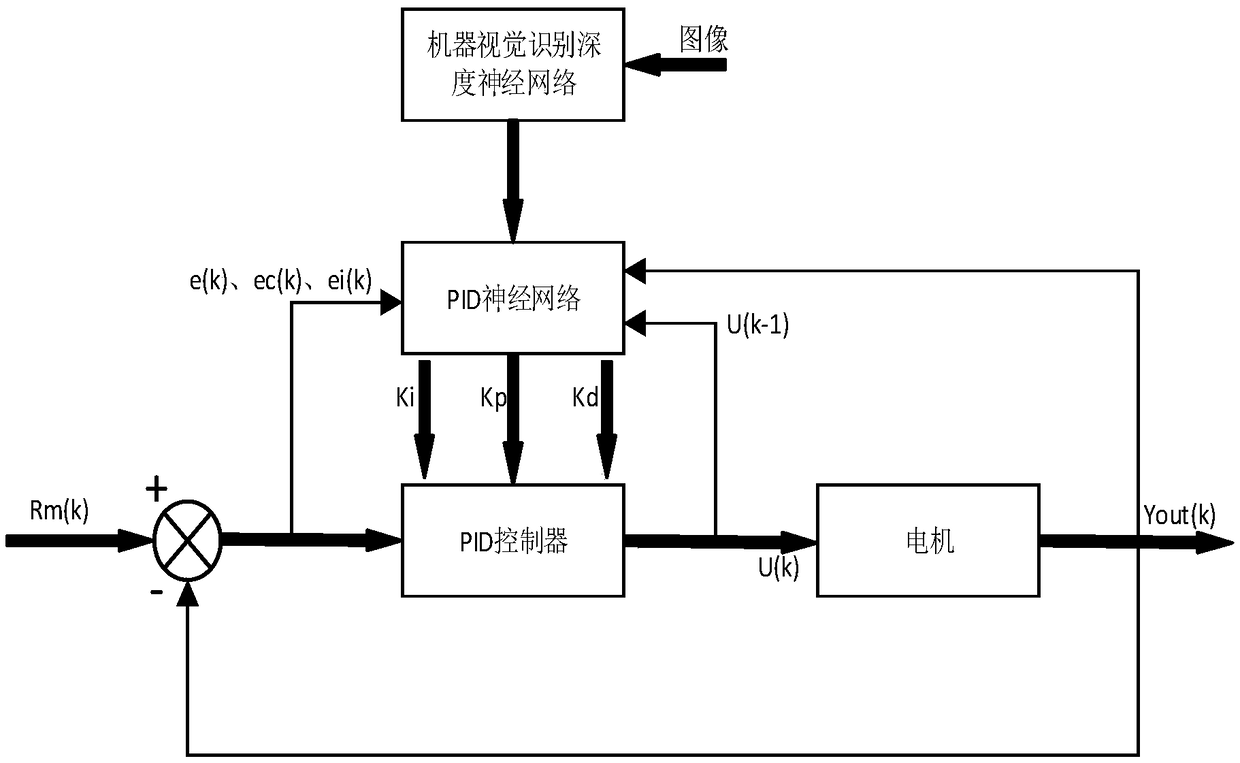

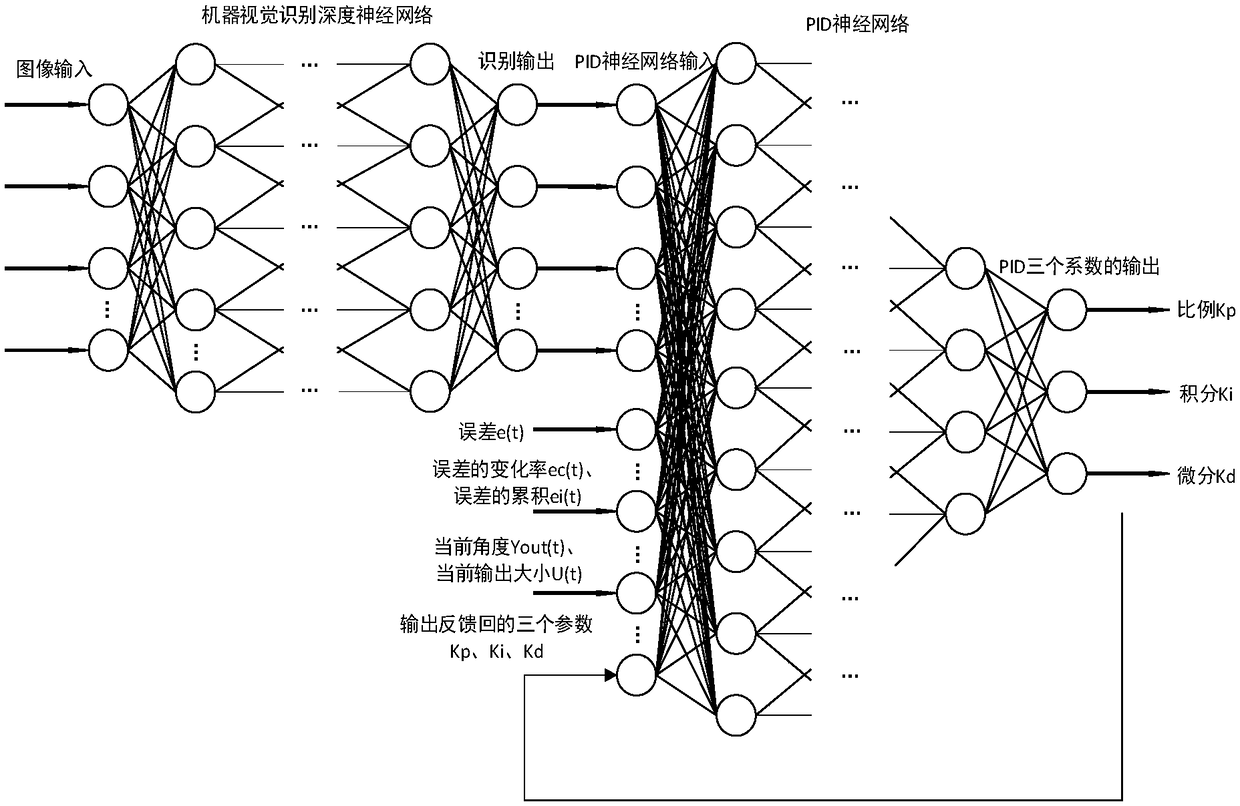

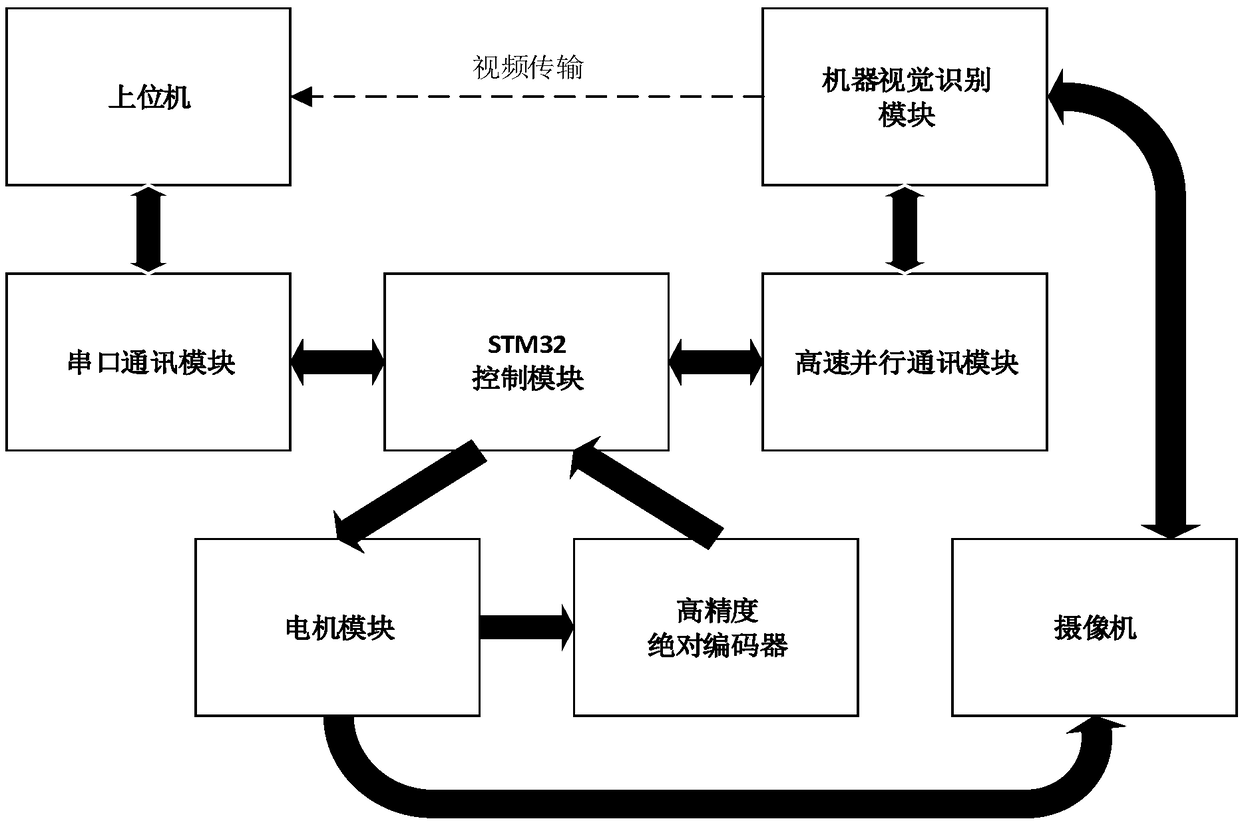

[0025] see figure 1 , the present invention combines the machine vision recognition deep neural network with the PID neural network to realize the control of the steering gear. The control principle and steps are as follows: the host computer inputs the target angle value Rm(k), and the system subtracts the current actual angle value Yout(k) from it to obtain the error value e(k) and its rate of change ec(k), The cumulative value ei(k), input these three values into the PID neural network, and at the same time, the current actual angle value of the motor after the last output of the PID controller and the output value U(k-1) of the last PID controller are also input to the PID neural network, and the feature data of the image obtained from the machine vision recognition de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com