Lens detection device used on stream line

A detection device and assembly line technology, applied in the direction of transmittance measurement, etc., can solve the problems of high error rate and low efficiency of light transmittance detection of batches of lenses, and achieve the effects of avoiding pollution, improving efficiency and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

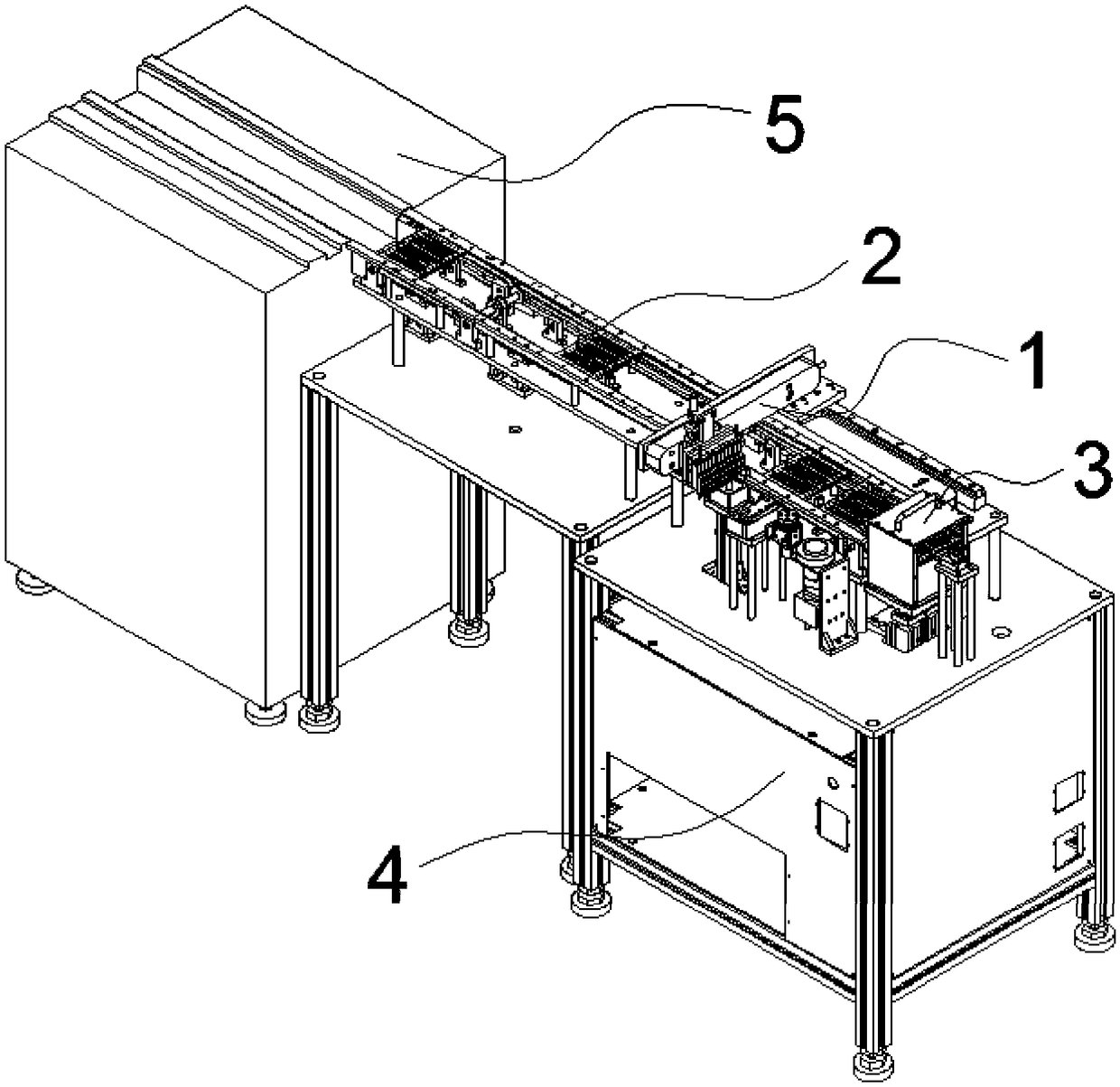

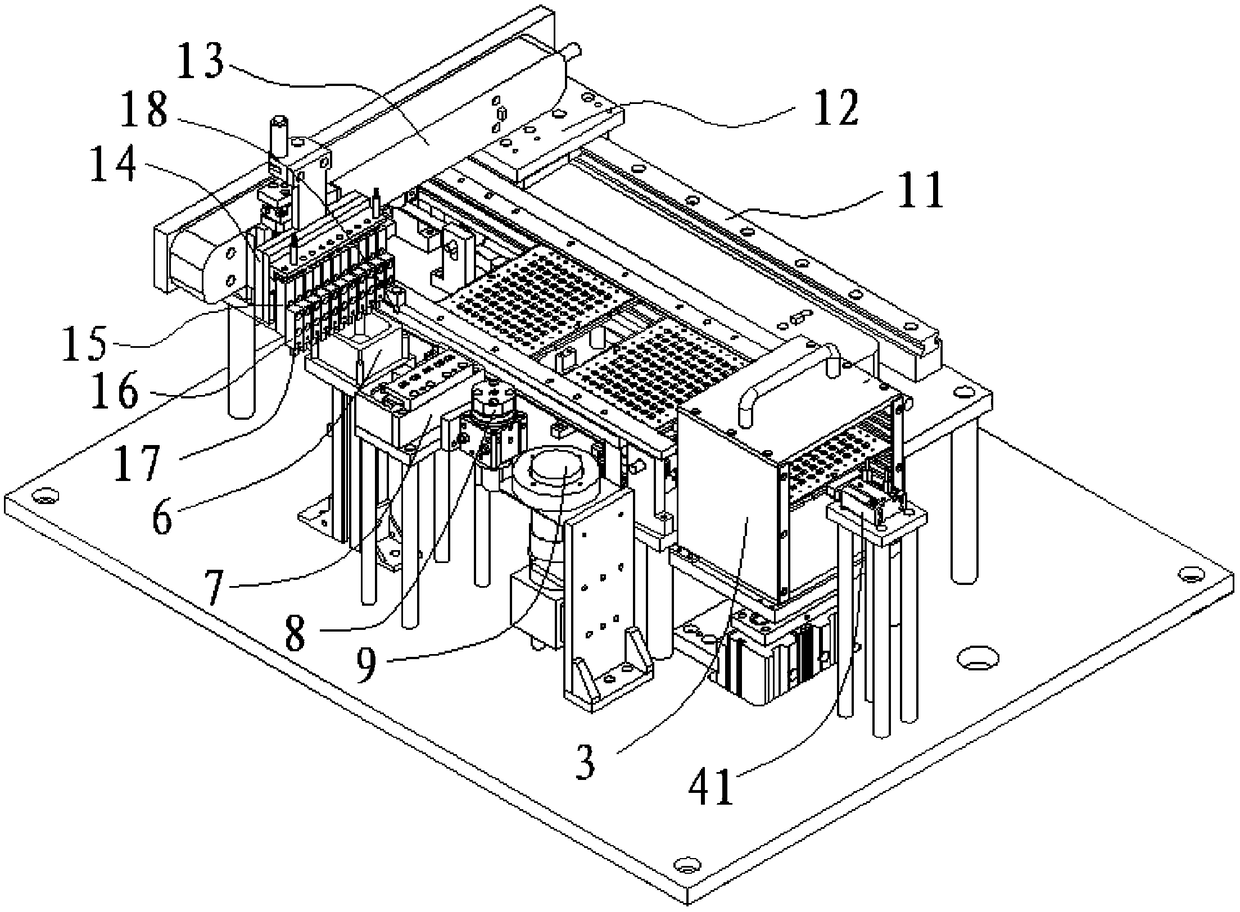

[0033] Such as Figure 1-6 As shown, it includes: removal part 1, conveyor belt 2, storage part 3, drive box 4, feeding part 5, collection part 6, cleaning part 7, detection part 8, control part 9, slide rail 11, sliding base Seat 12, cross arm 13, traverse slider 14, first cylinder group 15, second cylinder group 16, suction cup 17, positioning device 18, plate positioning device 41, lifting device 42, connecting tray 43, support seat 411, Abutting cylinder 412, abutting block 413, cylinder 71, dust collecting plate 72, card slot 73, fixing seat 81, fixing slot 82, light transmission hole 83, rotating shaft 84 and collecting part 85;

[0034] Such as figure 1 As shown, one end of the conveyor belt 2 abuts against the feeding part 5, and the feeding part 5 transports the lens to be inspected to the conveyor belt 2 by shaking; the other end of the conveyor belt 2 abuts against the storage part 3, and the storage part 3 3 is used to collect and store the detected lenses; the b...

Embodiment 2

[0043] Compared with Embodiment 1, Embodiment 2 is based on Embodiment 1. A collection unit 6 is set on one side of the conveyor belt 2. After the light transmittance of the lens is detected, the removal unit 1 sucks the lens and moves to the collection unit. Above the part 6, unqualified lenses are put into the collection part 6, which improves the recycling efficiency of unqualified lenses, and also prevents unqualified lenses from being mixed into qualified lenses, affecting the use effect of the lenses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com