Novel foam concrete wall body building block

A foamed concrete and wall technology, applied in the field of block manufacturing, can solve the problems of occupying a large production site, large dust and noise, restricting the development of the production scale of foamed concrete blocks, etc., to achieve overall performance reinforcement, load-bearing capacity enhancement, The effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

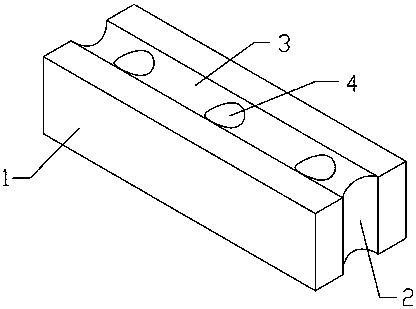

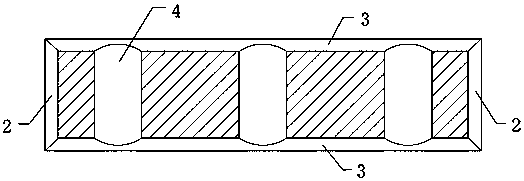

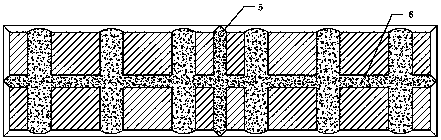

[0024] Such as Figures 1 to 6 A new type of foam concrete wall block is shown, which includes a brick body 1, and the brick body 1 is provided with an arc-shaped brick body connecting joint 2, a transverse channel 3 of an arc-shaped groove and a vertical channel 4 of a circular hole, The brick body 1 is made of foam concrete, and its shape is rectangular. The front and rear sides of the brick body 1 are rectangular planes. The left and right sides of the brick body are provided with arc-shaped brick joints 2, and the upper and lower sides are equipped with arc-shaped grooves. 3. There are usually three vertical channels running through the circular holes on both sides of the brick body inside. 4. When building the wall, the circular holes are filled with small stones and conc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap