Ultra-light composite beam structure suitable for large-span bridge and construction method of ultra-light composite beam structure suitable

A composite beam and ultra-light technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of high cost of UHPC, high tensile stress at joints, and reduced tensile strength, achieving small pouring volume and less welding volume , to avoid the effect of shrinkage cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

[0056] Unless otherwise defined, all technical terms used hereinafter have the same meanings as commonly understood by those skilled in the art. The terminology used herein is only for the purpose of describing specific embodiments, and is not intended to limit the protection scope of the present invention.

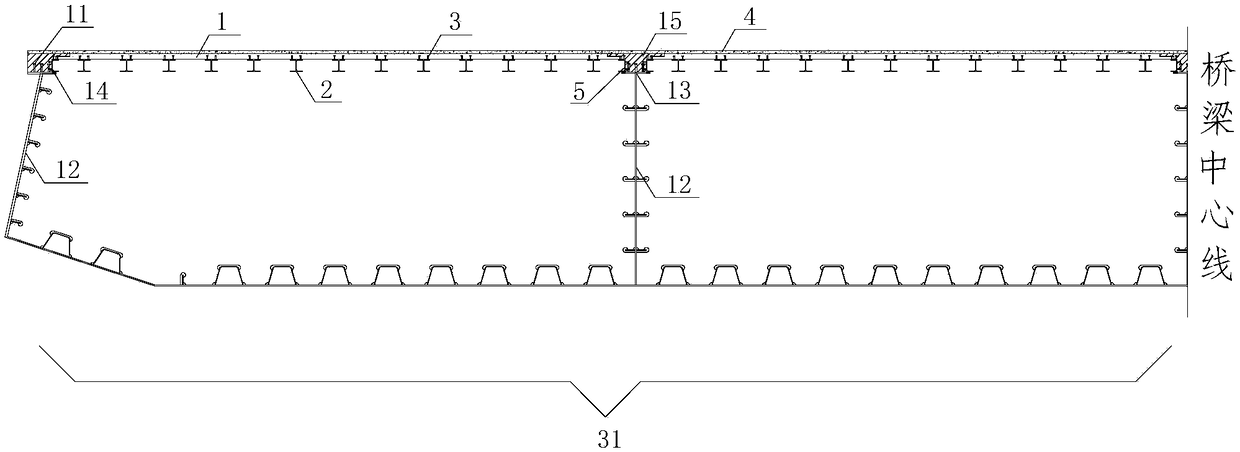

[0057] refer to Figure 1-8 , Figures 12 to 18 , an ultra-light composite beam structure suitable for long-span bridges in this embodiment, the ultra-light composite beam structure is mainly composed of a lower steel beam and an upper section steel-UHPC light composite bridge deck unit.

[0058] The steel girder can be PK steel girder 30, steel box girder 31, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com