A kind of textile size used for sizing pure cotton fabric warp yarn without pva and low sizing rate

A technology of textile size and size, which is applied in the field of textile size, can solve the difficulty of increasing the COD value of desizing wastewater, the difficulty of desizing wastewater treatment and the cost of wastewater treatment, affecting the performance of dyeing and finishing processing and product quality, and increasing the desizing treatment To solve problems such as difficulty and cost, achieve the effects of improving wear resistance and hairiness, easy handling, and low COD content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

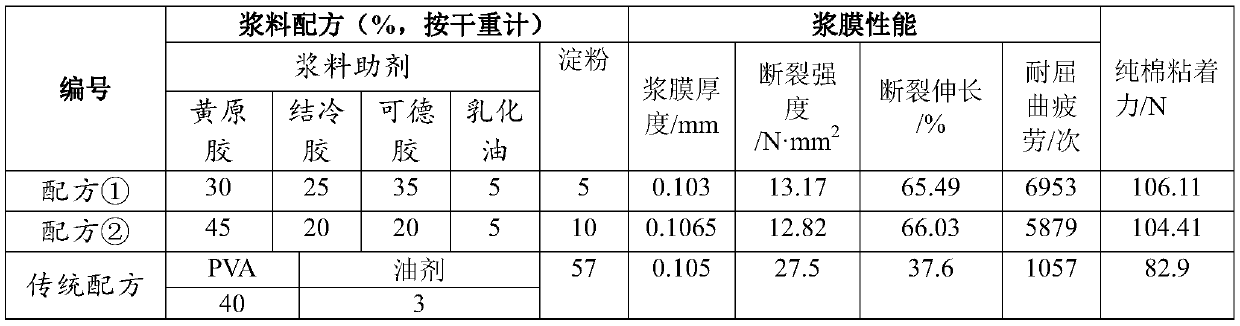

[0035] Two kinds of slurries were prepared, and the formulas were as shown in Table 1 (wherein the starch in the formula ① was starch acetate, and in the formula ② was cornstarch), according to the formulas ① and ② in Table 1, a 6% concentration slurry was prepared at 95° C. Cook the slurry for 1 hour, cool it to 80°C, cast a size film on the polyester film adjusted to the level, dry it under constant temperature and humidity conditions, and measure its performance. The serous film thickness is tested by a thickness gauge, the elongation is tested by an electronic strength tester, the buckling fatigue resistance is tested by a reciprocating buckling fatigue tester, and the adhesion is tested by a roving method.

[0036] It can be seen that the re-break elongation and cotton adhesion of the size film prepared by the two kinds of formulas of the present invention are significantly improved, especially the buckling fatigue resistance, which is 4-5 times higher than that of the tra...

Embodiment 2

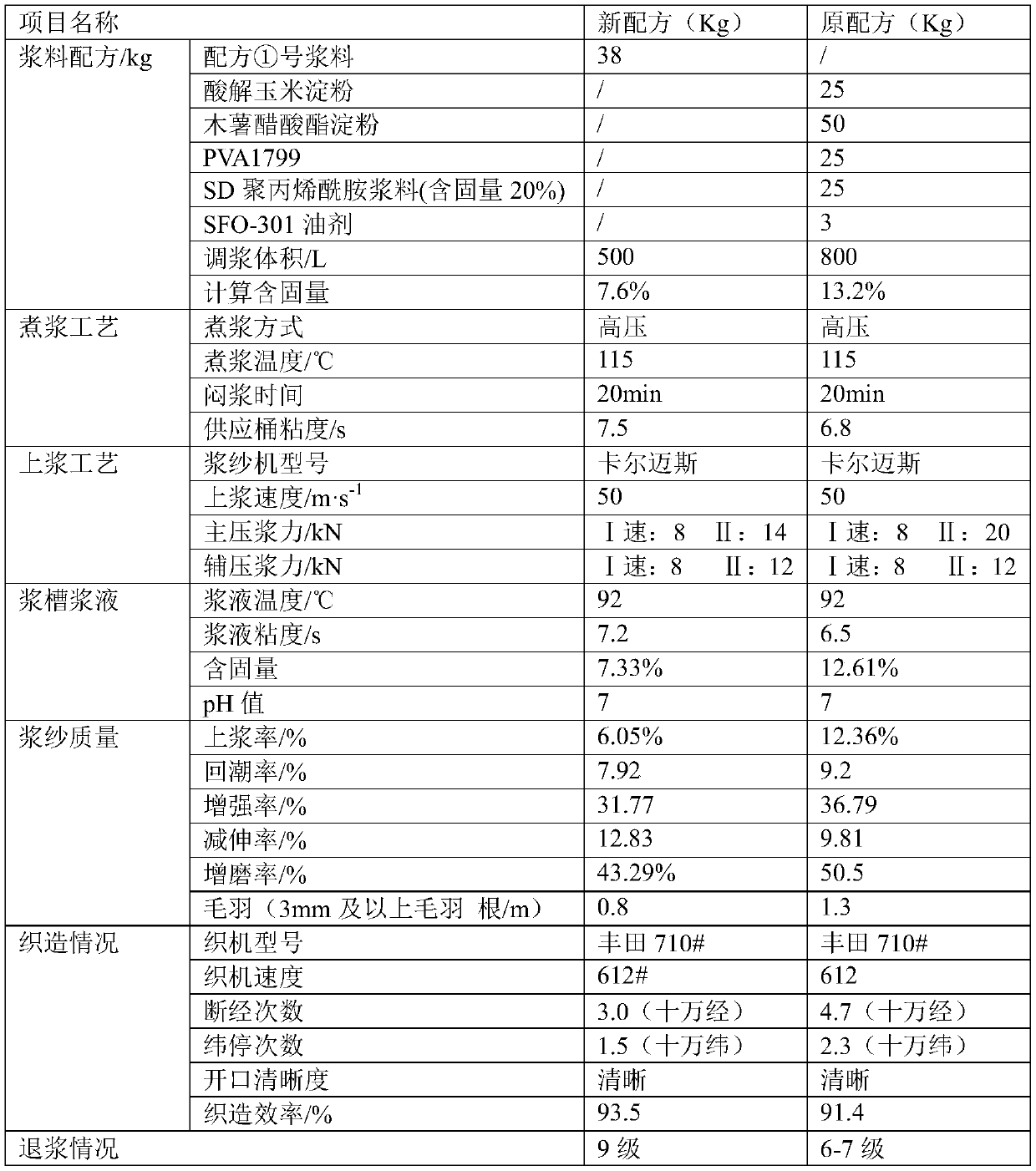

[0040] Fabric type: width 99cm, pure cotton compact spinning 40×40, gray fabric density: 547×283 (root / 10cm), plain weave.

[0041] Firstly, according to the formulas in Table 1 and Table 2 below, the new size ① size and the original size size are prepared respectively; secondly, the size is put into the sizing tank of the sizing machine, and the warp yarn is sized by double dipping and double pressing. Yarn, using amylase and 80 ℃ hot water desizing. The equipment and conditions are shown in Table 2 below.

[0042] Experimental parameters and results involved in table 2 embodiment 2

[0043]

[0044] As can be seen from the above, the original formula has used 25Kg PVA (accounting for 23.8% of the whole size), the sizing rate reaches 12.36%, and the weaving efficiency is 91.4%, and the size is not easy to desizing, and the desizing grade has only 6-7 grades.

[0045] The new formula does not use PVA size at all, the amount of size used is only 38Kg, far less than the 128...

Embodiment 3

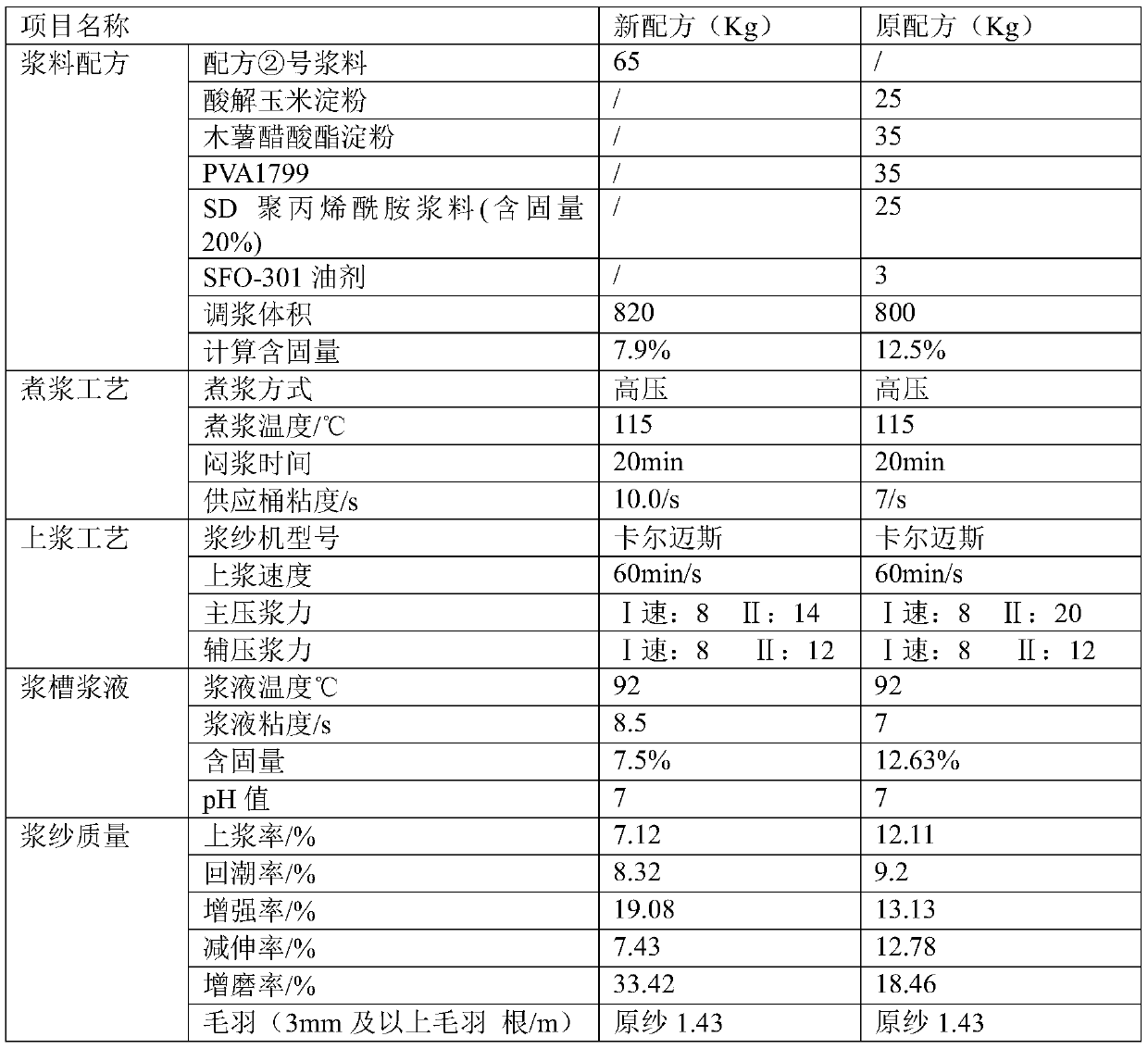

[0047] Variety: width 96.5cm, pure cotton warp yarn count 50×50, gray fabric density: 566.5×275.5 (threads / 10cm), plain weave.

[0048] Sizing step is identical with embodiment 2, and concrete condition setting sees the following table 3:

[0049] Experimental parameters and results involved in table 3 embodiment 3

[0050]

[0051]

[0052] The finer the yarn count, the more difficult it is to weave, and the higher the requirements for sizing.

[0053] As can be seen from above, the original formula has used 35Kg PVA (accounting for 35% of the whole size), the sizing rate reaches 12.11%, and the weaving efficiency is 89.4%.

[0054] The new formula does not use PVA size at all, the amount of size used is only 65Kg, and the amount of size used is only about half of the original formula. The sizing rate of the present invention is only 7.12%, the weaving efficiency reaches 91.5%, and the size desizing performance is good. It is easy to retreat, the desizing grade reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com