High-strength sealant for electronic product and preparation method of high-strength sealant

A technology for electronic products and sealants, applied in adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problems of low tear resistance, achieve long service life and reduce costs , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

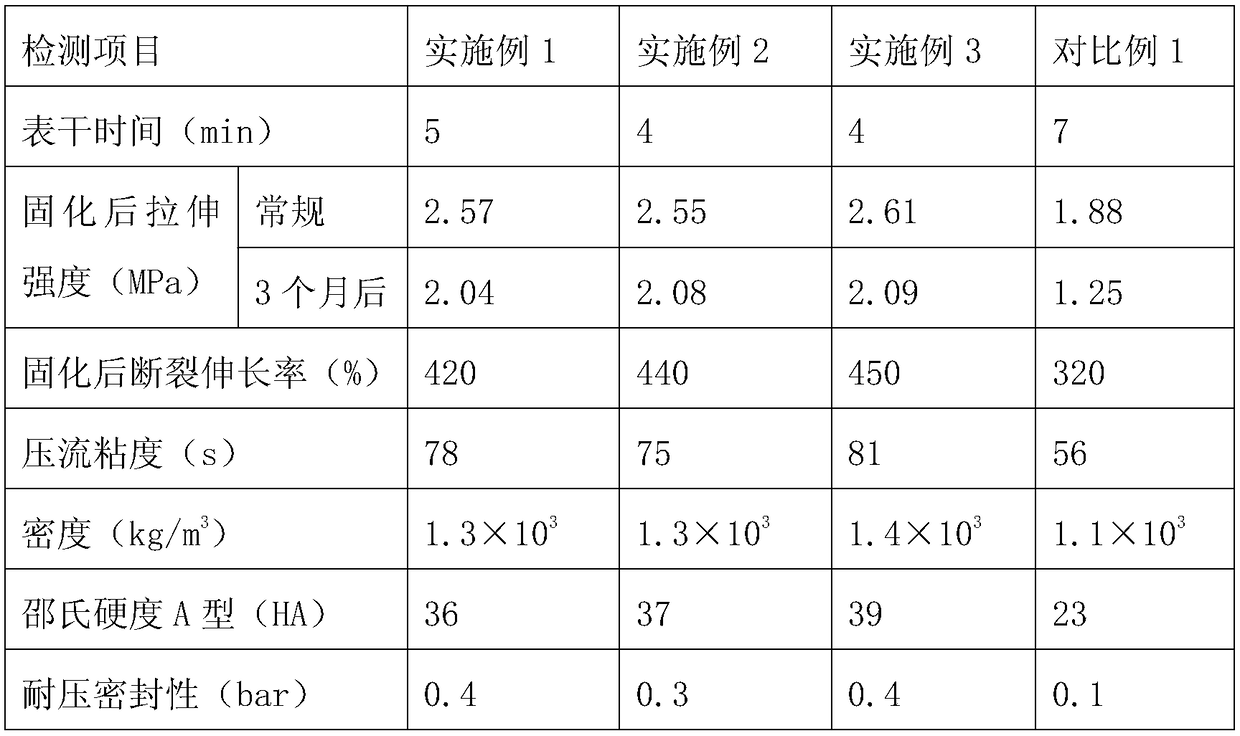

Examples

Embodiment 1

[0031] A high-strength sealant for electronic products, comprising the following raw materials by weight: 25 parts of waste rubber, 20 parts of epoxy resin, 23 parts of acrylic acid, 6 parts of monolauryl phosphate, 5 parts of dioctyl phthalate, 7 parts of polyether polyol, 6 parts of nano calcium carbonate, 5 parts of titanium dioxide, 13 parts of epoxidized soybean oil, 17 parts of modified lignin, 7 parts of isocyanate, 7 parts of silane coupling agent, 6 parts of amine catalyst and antioxidant 3 parts of oxidizing agent.

[0032] A preparation method of high-strength sealant for electronic products, comprising the following preparation steps:

[0033] a. Mix nano-calcium carbonate, titanium dioxide and isocyanate, introduce into the reaction kettle, heat up to 88°C, vacuumize, carry out stirring reaction for 0.6h, then cool down to 75°C, and keep warm to obtain mixture 1;

[0034] b. Mix the modified lignin, polyether polyol, acrylic acid and amine catalyst, introduce int...

Embodiment 2

[0043] A high-strength sealant for electronic products, comprising the following raw materials by weight: 28 parts of waste rubber, 20 parts of epoxy resin, 19 parts of acrylic acid, 10 parts of monolauryl phosphate, 7 parts of dioctyl phthalate, 7 parts of polyether polyol, 9 parts of nano calcium carbonate, 6 parts of titanium dioxide, 10 parts of epoxidized soybean oil, 17 parts of modified lignin, 9 parts of isocyanate, 6 parts of silane coupling agent, 6 parts of amine catalyst and antioxidant 3 parts of oxidizing agent.

[0044] A preparation method of high-strength sealant for electronic products, comprising the following preparation steps:

[0045] a. Mix nano-calcium carbonate, titanium dioxide and isocyanate, introduce into the reaction kettle, heat up to 85°C, vacuumize, carry out stirring reaction for 0.6h, then cool down to 80°C and keep warm to obtain mixture 1;

[0046] b. Mix the modified lignin, polyether polyol, acrylic acid and amine catalyst, introduce int...

Embodiment 3

[0055] A high-strength sealant for electronic products, comprising the following raw materials by weight: 32 parts of waste rubber, 24 parts of epoxy resin, 21 parts of acrylic acid, 8 parts of monolauryl phosphate, 5 parts of dioctyl phthalate, 5 parts of polyether polyol, 7 parts of nano calcium carbonate, 9 parts of titanium dioxide, 12 parts of epoxidized soybean oil, 155 parts of modified lignin, 10 parts of isocyanate, 4 parts of silane coupling agent, 4 parts of amine catalyst and antioxidant 5 parts of oxidizing agent.

[0056] A preparation method of high-strength sealant for electronic products, comprising the following preparation steps:

[0057] a. Mix nano-calcium carbonate, titanium dioxide and isocyanate, introduce into the reaction kettle, heat up to 85-88°C, vacuumize, carry out stirring reaction for 0.6h, then cool down to 80°C and keep warm to obtain mixture 1;

[0058] b. Mix the modified lignin, polyether polyol, acrylic acid and amine catalyst, introduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com