Application of fluorescent tracer type itaconic acid and aspartic acid copolymer in preparation of water treatment agent

A technology of itaconate-aspartic acid copolymer and itaconate-aspartic acid, which can be used in water/sludge/sewage treatment, fluorescence/phosphorescence, luminescent materials, etc., can solve the limitation of development and application, and react raw materials Rare, decomposition and other problems, to achieve the effect of online dosing, simplify on-site operation, and reduce interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Weigh 10 g (36.09 mmol) of 4-bromo-1,8-naphthalene anhydride into a three-necked flask, add 30 mL of ethanol, stir slowly, and drop N,N-dimethyl-1,3-propanediamine 9.1 The mixed solution of mL (72.18mmol) and 20mL ethanol was dripped in half an hour, and slowly rose to reflux temperature at the same time, followed by thin-layer chromatography until the reaction was completed, cooled and filtered to obtain a yellow solid, and recrystallized from ethanol to obtain the target product ( I).

[0033] Weigh 5 g (13.84 mmol) of the product (I) generated above in a three-necked flask, add 20 mL of ethylene glycol methyl ether, stir slowly, add dropwise a mixture of 2.7 mL (27.7 mmol) of n-butylamine and 10 mL of ethanol, and simultaneously Slowly rise to 130°C, followed by thin-layer chromatography until the end of the reaction, suction filtration under reduced pressure to remove excess ethylene glycol methyl ether, DMF recrystallization, to obtain the target product ...

Embodiment 2

[0035] Example 2 Put 40mL of deionized water, aspartic acid 9.3g (0.28mol), sodium hydroxide 0.16g and fluorescent monomer (FT ) 0.3g, heated up to 80°C under stirring, passed nitrogen to remove oxygen, and under the protection of nitrogen, added dropwise 15g of 30% hydrogen peroxide solution (accounting for about 10% of monomer mass), 50mL of itaconic acid solution (Containing IA 36.4g, 0.28mol), dripping finished within 2h, continued to keep warm for 1h, cooled and discharged to obtain the product FT-IA-ASP (brown liquid) of the present invention.

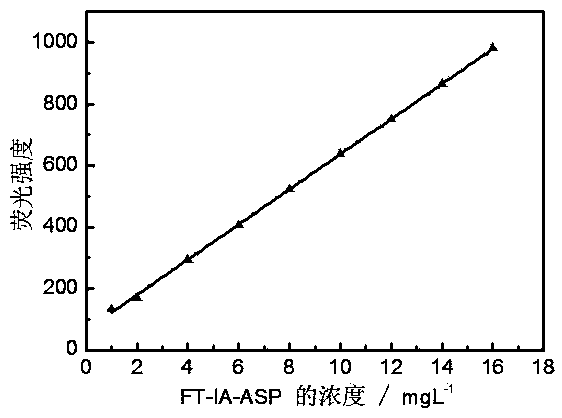

[0036] The excitation wavelength and emission wavelength of the polymer are similar to those of the fluorescent monomer, which are also 474nm and 554nm respectively. figure 1 , that is, the wavelength does not shift after polymerization. At the same time, the concentration of the polymer and the relative fluorescence intensity have a good linear relationship, the linear correlation coefficient is 0.99968, and the detection limit...

Embodiment 3

[0038] Example 3 The static scale inhibition method was used to evaluate the scale inhibition performance of the fluorescent polymer on calcium carbonate. The test conditions are as follows:

[0039] Temperature: 80°C; Drug: the product of Example 2; Dosing concentration: 2, 4, 6, 8, 10, 12, 14, 16, 18, 20mg·L -1 ;Test time: 10h; Test configuration water: Ca 2+ 250mg·L -1 , HCO 3 - 250mg·L -1 (both CaCO 3 Calculated), the concentration factor is 1.5 times; at the same time, do a blank experiment without adding medicament. According to this method, the dosage of the drug is 12mg L -1 , the scale inhibition rate to calcium carbonate is 96.1%. see attached results Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence wavelength | aaaaa | aaaaa |

| anti-scaling ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com