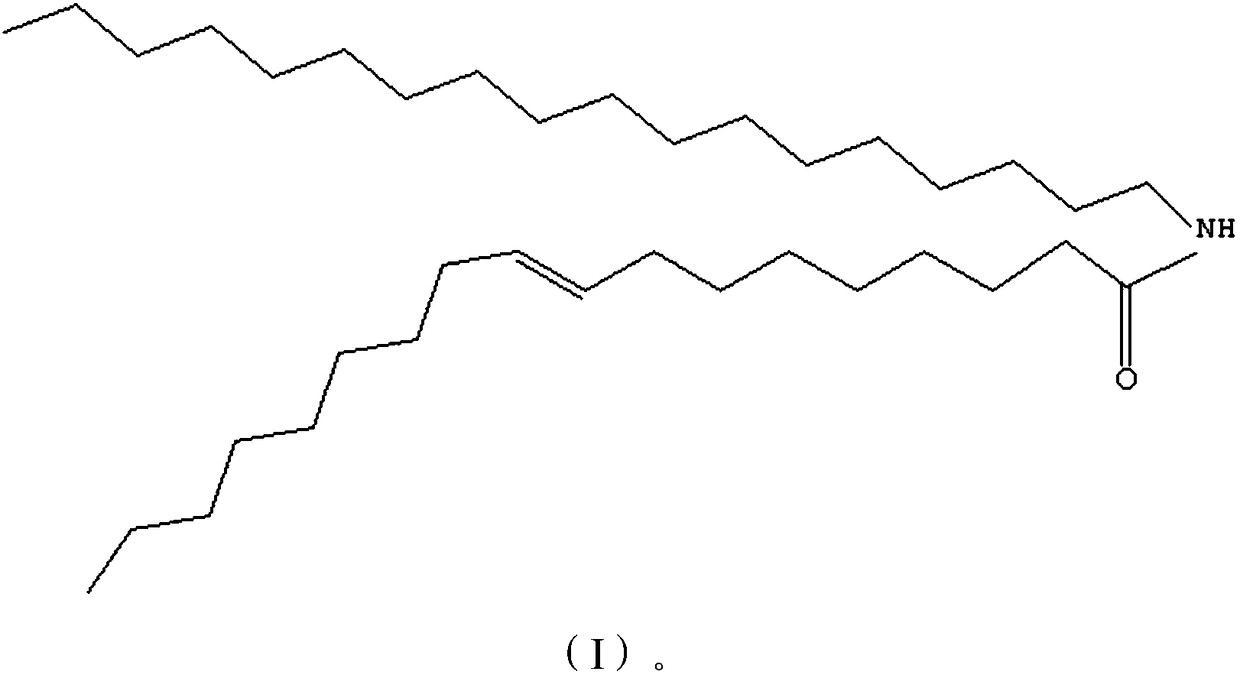

Octadecyl oleamide, preparation method and application thereof

A technology of octadecyl oleic acid amide and octadecyl amine is applied in the preparation of carboxylic acid amide, chemical instruments and methods, preparation of organic compounds, etc., and can solve the problems of unstable product quality, single function and complex production process To solve problems such as chemistry and so on, to achieve the effects of high product purity and stability, high synthesis conversion rate, and significant lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of octadecyl oleic acid amide comprises the steps of: taking oleic acid and octadecylamine as raw materials, taking oleic acid and octadecylamine in a molar ratio of 1.005:1, adding a catalyst of 0.45% of the total weight of raw materials , at a temperature of 185° C. and a pressure of 0.5 MPa, react for 6 hours to obtain octadecyl oleic acid amide; wherein, the composition of the catalyst includes: 85% SiO 2 , 14.5% TiO 2 and 0.5% La2 o 3 .

[0024] In this example, the synthetic conversion rate (calculated as C18) of octadecyl oleic acid amide is >98.5%, the purity (total amide content) is >=98.5%, and the product yield is >=95.5%.

Embodiment 2

[0026] Application of octadecyl oleic acid amide to prepare PP film: add octadecyl oleic acid amide to the screw extruder together with PP resin, maleic anhydride grafted PP, sodium stearate and antioxidant 168 in an amount of 5‰ Melt and mix in the machine, and prepare PP film-1 through extrusion and biaxial stretching process.

[0027] In addition, without adding stearyl oleic acid amide, directly add PP resin, maleic anhydride grafted PP, sodium stearate and antioxidant 168 into the screw extruder to melt and mix, and prepare by extrusion and biaxial stretching process into PP film-2.

[0028] According to GB / T 12802.2-2004 standard, the antistatic performance of PP film was tested. After testing, the surface resistivity of PP film-1 was 10 10 Ω, the surface resistivity of PP film-2 is 10 12 Ω.

[0029] Example 2

[0030] Preparation of PP scratch-resistant masterbatch: In terms of mass percentage, take 70% epoxy resin, 15% octadecyl oleic acid amide, 1% maleic anhydrid...

Embodiment 3

[0033] Preparation of anti-scratch and antistatic masterbatch: 75% PE, 10% stearyl oleic acid amide, 5% stearylamine polyoxyethylene ether, 5% monoglyceride and 5% hydroxyethyl Ethylene bis stearamide is mixed, melted and granulated to obtain scratch-resistant and anti-static masterbatch.

[0034] After testing, the PP film made of the above-mentioned scratch-resistant and anti-static masterbatch was measured to have a surface resistivity of 10 10 Ω, and its color difference value is 0.42, indicating that the prepared PP film has good scratch resistance and antistatic properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| color price | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com