Cement grinding aid

A cement grinding aid and solvent technology, applied in the field of cement grinding aids, can solve problems such as increasing the production cost of a cement plant, and achieve the effects of saving cement grinding power consumption, reducing dissolution, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

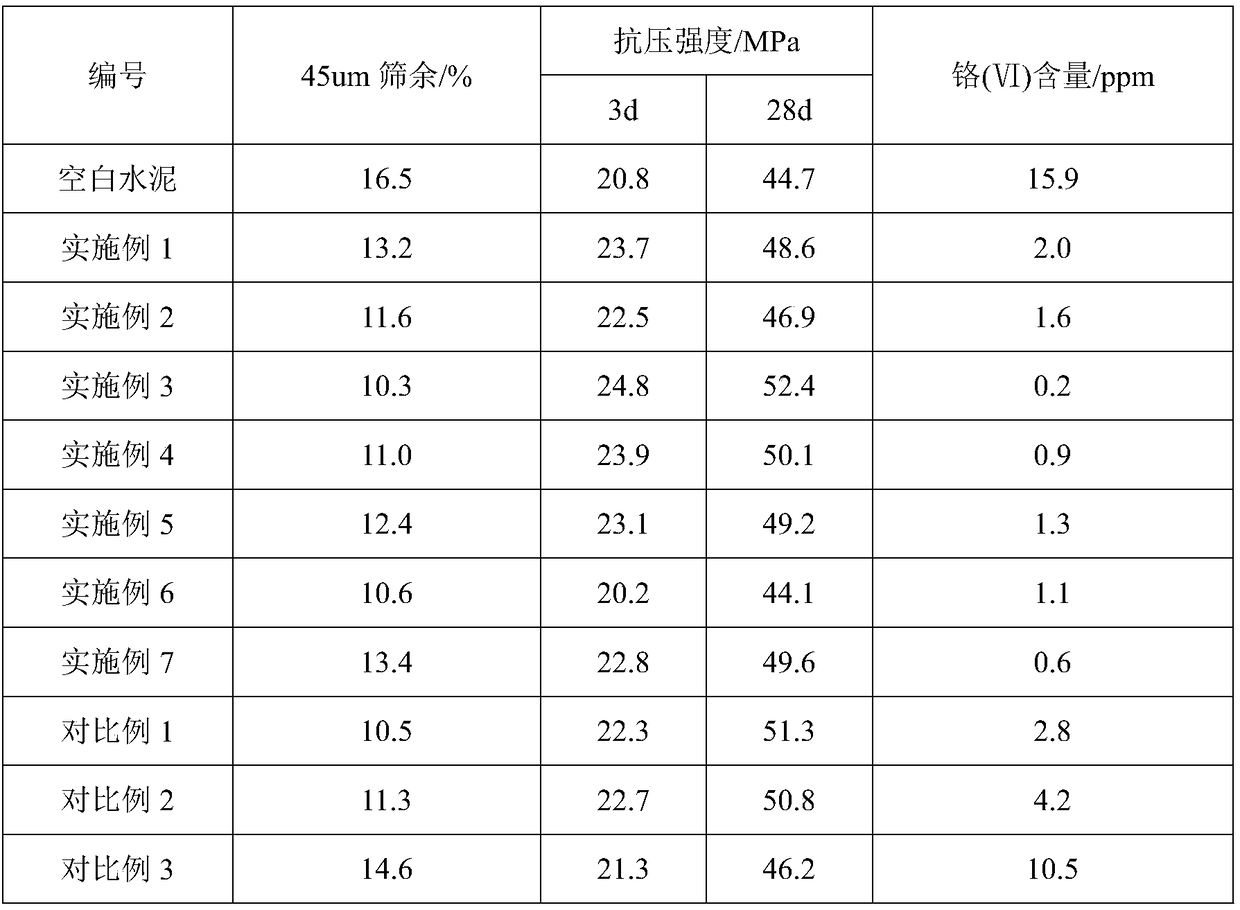

Examples

Embodiment 1

[0023] A cement grinding aid, consisting of the following substances by weight fraction: 8% of phosphorous anhydride-ethylene glycol reactant, 3% of polycarboxy compound, 3% of grinding aid, 5% of potassium pyrosulfite, and 0.1% of defoamer %, the balance is water.

[0024] The preparation method of described phosphorous anhydride-ethylene glycol reactant is as follows: add ethylene glycol, phosphorous anhydride (P 4 o 6 ), a catalyst and a reaction solvent, the temperature is raised to 80° C., and the solvent is distilled off under reduced pressure, which is the phosphorous anhydride-ethylene glycol reactant.

[0025] The catalyst is concentrated sulfuric acid.

[0026] The solvent is acetone.

[0027] The molar ratio of ethylene glycol to phosphorous anhydride is 4:1.

[0028] The dosage of the catalyst is 1% of the total weight of ethylene glycol and phosphorous anhydride.

[0029] The polycarboxy compound is trisodium nitrilotriacetate.

[0030] The grinding aid subs...

Embodiment 2

[0033] A cement grinding aid, consisting of the following substances in weight fractions: 12% of phosphorous anhydride-ethylene glycol reactant, 1% of polycarboxy compound, 5% of grinding aid, 1% of potassium pyrosulfite, and 1% of defoamer %, the balance is water.

[0034] The preparation method of described phosphorous anhydride-ethylene glycol reactant is as follows: add ethylene glycol, phosphorous anhydride (P 4 o 6 ), a catalyst and a reaction solvent, the temperature is raised to 40° C., and the solvent is distilled off under reduced pressure, which is the phosphorous anhydride-ethylene glycol reactant.

[0035] The catalyst is anhydrous sodium acetate.

[0036] The solvent is tetrahydrofuran.

[0037] The molar ratio of ethylene glycol to phosphorous anhydride is 12:1.

[0038] The dosage of the catalyst is 5% of the total weight of ethylene glycol and phosphorous anhydride.

[0039] The polycarboxy compound is diethyltriaminepentaacetic acid.

[0040] The grindi...

Embodiment 3

[0043] A cement grinding aid, consisting of the following substances in weight fractions: 10% of phosphorous anhydride-ethylene glycol reactant, 2% of polycarboxy compound, 4% of grinding aid, 3% of potassium metabisulfite, and 0.6% of defoamer %, the balance is water.

[0044] The preparation method of described phosphorous anhydride-ethylene glycol reactant is as follows: add ethylene glycol, phosphorous anhydride (P 4 o 6 ), a catalyst and a reaction solvent, the temperature is raised to 60° C., and the solvent is distilled off under reduced pressure, which is the phosphorous anhydride-ethylene glycol reactant.

[0045] The catalyst is 2-naphthalenesulfonic acid.

[0046] The molar ratio of ethylene glycol to phosphorous anhydride is 8:1.

[0047] The dosage of the catalyst is 3% of the total weight of ethylene glycol and phosphorous anhydride.

[0048] The polycarboxy compound is trisodium hydroxyethyl ethylenediamine triacetate.

[0049] The grinding aid substance is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com