Preparation method of chitosan-based spherical negative lithium ion battery carbon electrode

A technology of lithium-ion batteries and chitosan, which is applied in the direction of battery electrodes, carbon preparation/purification, negative electrodes, etc., can solve the problems of no research on the performance of lithium battery negative electrodes, large surface area of nanoparticles, high hydrothermal reaction temperature, etc., and achieve good results Rate performance and cycle stability, a wide range of sources, and the effect of improving lithium storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

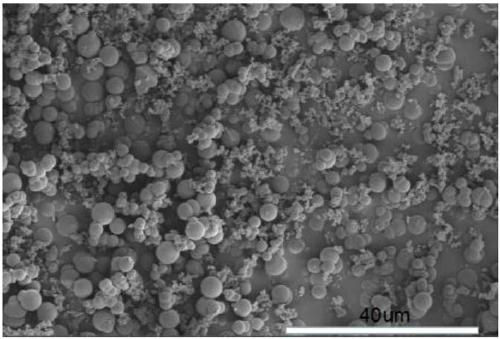

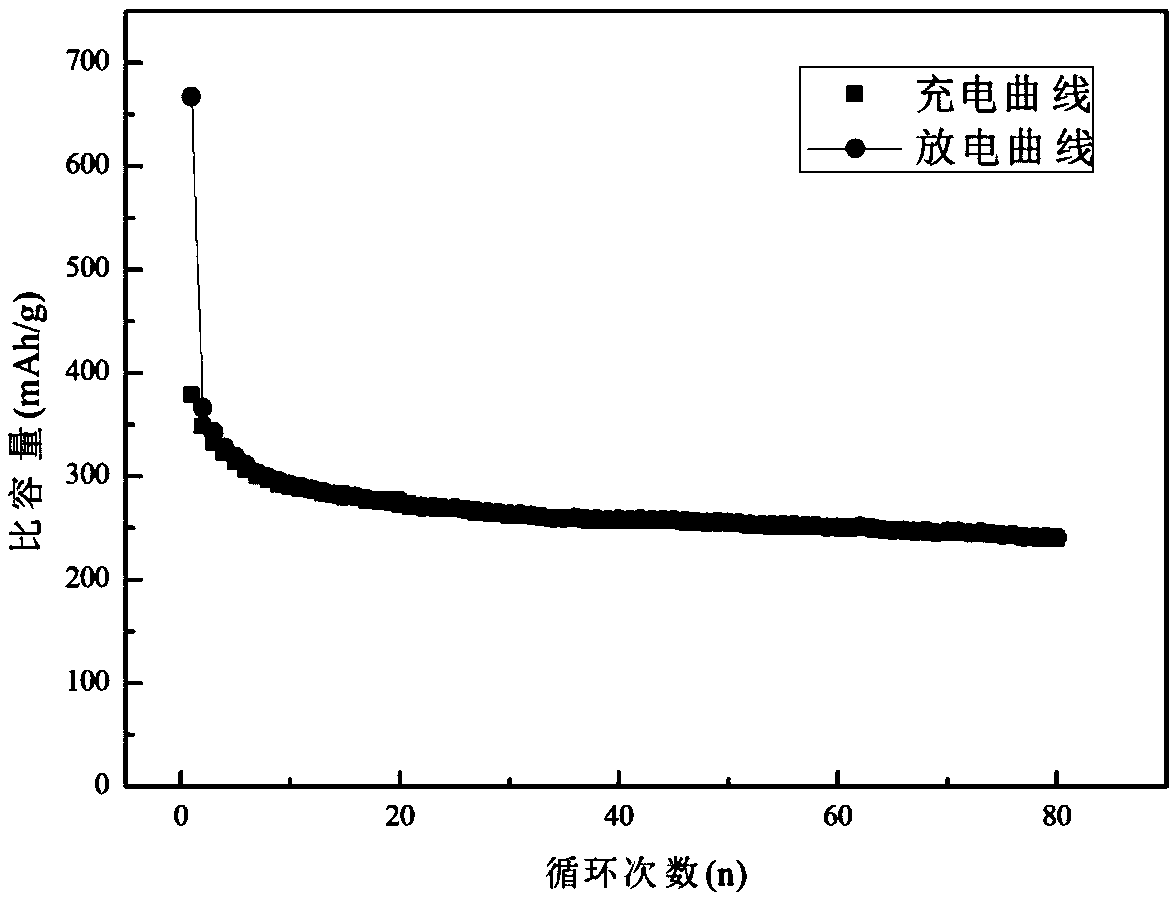

[0026] Dissolve 3g of chitosan in 65ml of 2.5M hydrochloric acid solution, stir in a water bath at room temperature for 3 hours, raise the temperature to 70°C and stir for 10 hours, add the evenly mixed solution to the stainless steel lined with polytetrafluoroethylene to react In the kettle, seal it and put it in an oven to react at 190°C for 7 hours. Cool naturally to room temperature, filter, wash, and dry to obtain hydrothermal carbon with a particle size distribution of 1.32-4.49um, and then carbonize at a high temperature of 700°C for 2 hours under an inert atmosphere to obtain a nitrogen-containing spherical carbon negative electrode material.

[0027] The obtained carbon microspheres were used as lithium-ion negative electrode materials to assemble the battery, and the working electrode was prepared according to the ratio of sample: conductive agent acetylene black: polyvinylidene fluoride = 92:3:5, and the metal lithium sheet was used as a reference electrode to test i...

Embodiment 2

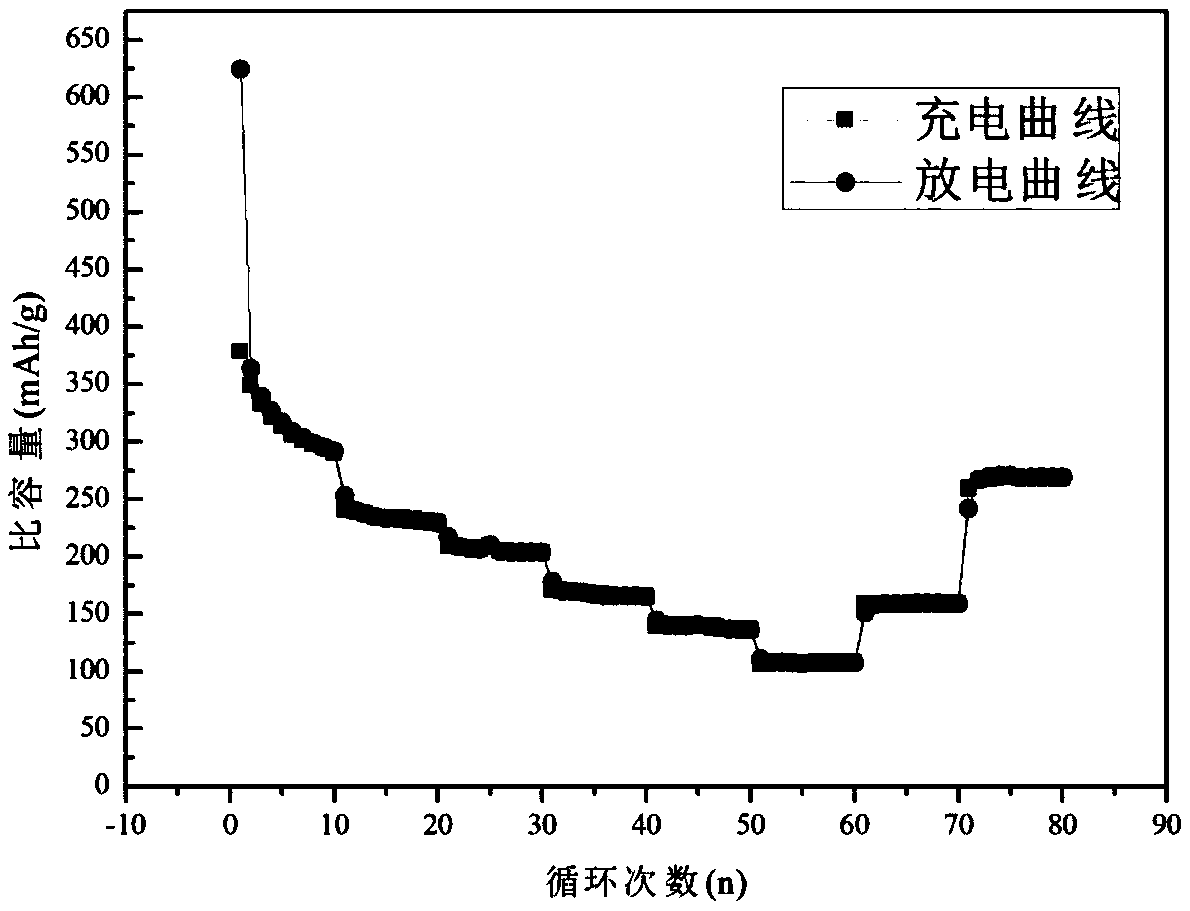

[0030] Dissolve 3g of chitosan in 65ml of 2.5M hydrochloric acid solution, stir in a water bath at room temperature for 3 hours, raise the temperature to 70°C and stir for 10 hours, add the evenly mixed solution to the stainless steel lined with polytetrafluoroethylene to react In the kettle, seal it and put it in an oven to react at 180°C for 7 hours. Cool naturally to room temperature, filter, wash, and dry to obtain hydrothermal carbon with a particle size distribution of 1.03-5.32um, and then carbonize at a high temperature of 700°C for 2 hours under an inert atmosphere to obtain a nitrogen-containing spherical carbon negative electrode material.

[0031] The obtained carbon material was assembled into a battery and tested for electrochemical performance. At a current density of 50mA / g, the initial discharge specific capacity was 579.9mAh / g, and the reversible specific capacity was 292.6mAh / g.

Embodiment 3

[0033] Dissolve 3g of chitosan in 65ml of 2.5M hydrochloric acid solution, stir in a water bath at room temperature for 3 hours, raise it to 70°C and stir for 10 hours, and add the uniformly mixed solution to a stainless steel reaction kettle lined with polytetrafluoroethylene After sealing, put it in an oven to react at 200°C for 10 hours. Naturally cooled to room temperature, filtered, washed, and dried to obtain a hydrothermal carbon sample.

[0034] The hydrothermal carbon sample was scanned by an electron microscope, the particle size distribution was 1-5.49um, and the carbon spheres were fused and cross-linked.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse specific capacity | aaaaa | aaaaa |

| Inverse specific capacity | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com