Towing machine with sliding device

A skid device and towing machine technology, applied in the field of towing machine equipment, can solve the problems affecting the safety and reliability of ship operation, the inability to effectively maintain the stability of traction force, and the poor stability of traction force output, so as to improve reliability and safety , Improve the stability of equipment operation, and the effect of wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

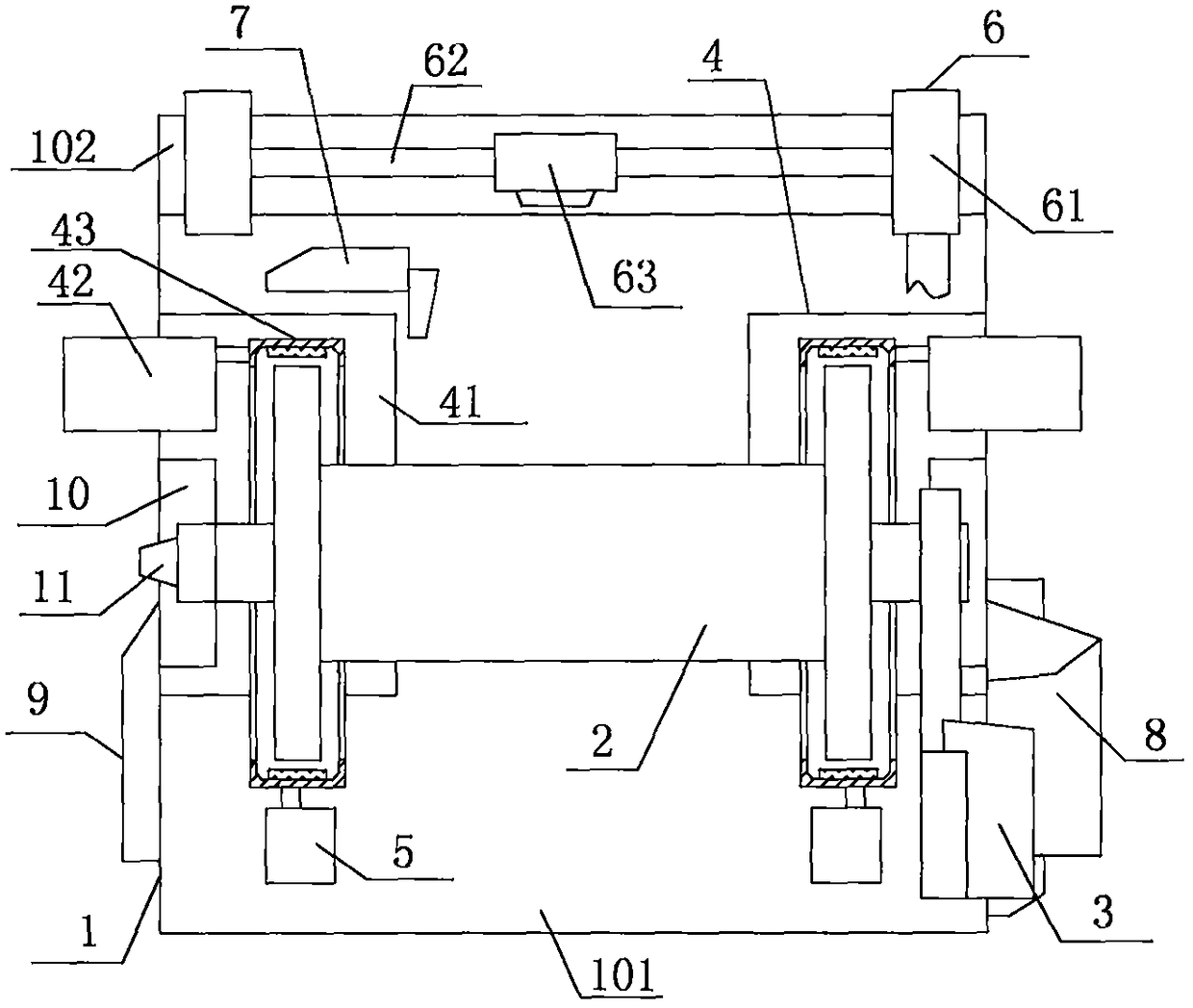

[0013] Attached below figure 1 The present invention will be described in detail with specific embodiments.

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0015] Such as figure 1 The towing machine with a skid device includes a load bearing base 1, a cable drum 2, a hydraulic motor drive device 3, a hydraulic brake 4, a cable discharge device 6, a force measuring device 5, and a rope length measuring device 7 , the hydraulic station 8 and the control circuit 9, wherein the carrier base 1 includes a base plate 101 and a side plate 102, the side plate 102 is located at the front end of the base plate 101, and is vertically distributed with the base plate 101, and the base plate 101 and the side plate 102 are both Frame structure, the twisted cable drum 2 is installed on the upper end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com