Self-adaptive processing method for front and rear edges of aero-engine stator blade

A technology for aero-engines and stator blades, applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve the problems of obvious cutting, flat head, edge trimming, etc., achieve strong versatility and practicability, and reduce manual intervention , The effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

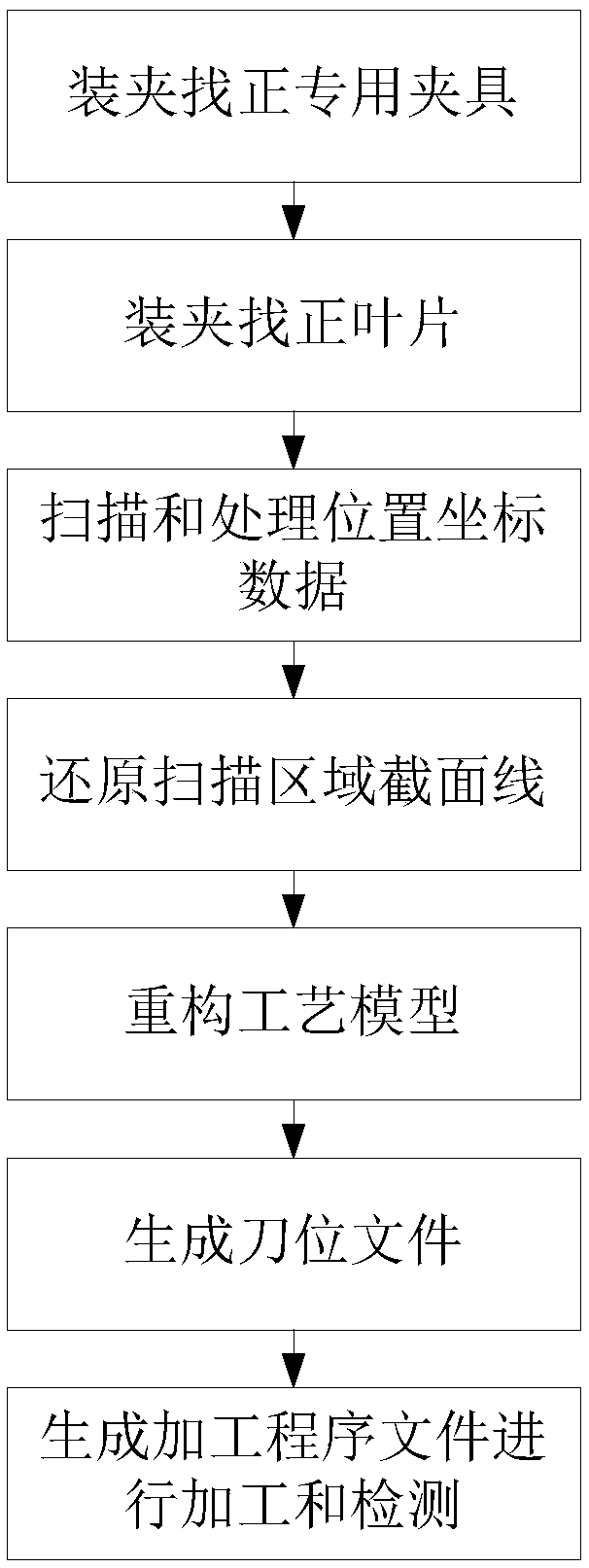

[0033] An adaptive processing method for leading and trailing edges of an aeroengine stator blade of the present invention adopts spatial geometry adaptive processing technology, collects coordinate data in corresponding areas of leading and trailing edges through a non-contact measurement system, and processes the data. According to the scanning data and theoretical model, the process model required for processing is constructed, and an adaptive tool position file is generated for the current part to complete the processing of the blade. The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0034] A method for self-adaptive processing of leading and trailing edges of an aeroengine stator blade of the present invention comprises the following steps:

[0035] Step 1. Clamping and aligning the special fixture: clamp the blade adaptive processing special fixture on the machine tool and align it, specifically:

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com