Judgment system and method for off-line detection of thermal resistance installation quality of continuous casting steel plate

An off-line detection and thermal resistance technology, which is applied in the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc., can solve the problem of maintaining the consistency of the heating temperature of the continuous casting steel plate, the difficulty of ensuring the consistency of the temperature of the continuous casting steel plate, heating The temperature can not be accurately controlled and other problems, to achieve the effect of low equipment cost, fast heating speed and good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0040] The technical scheme that the present invention solves the problems of the technologies described above is:

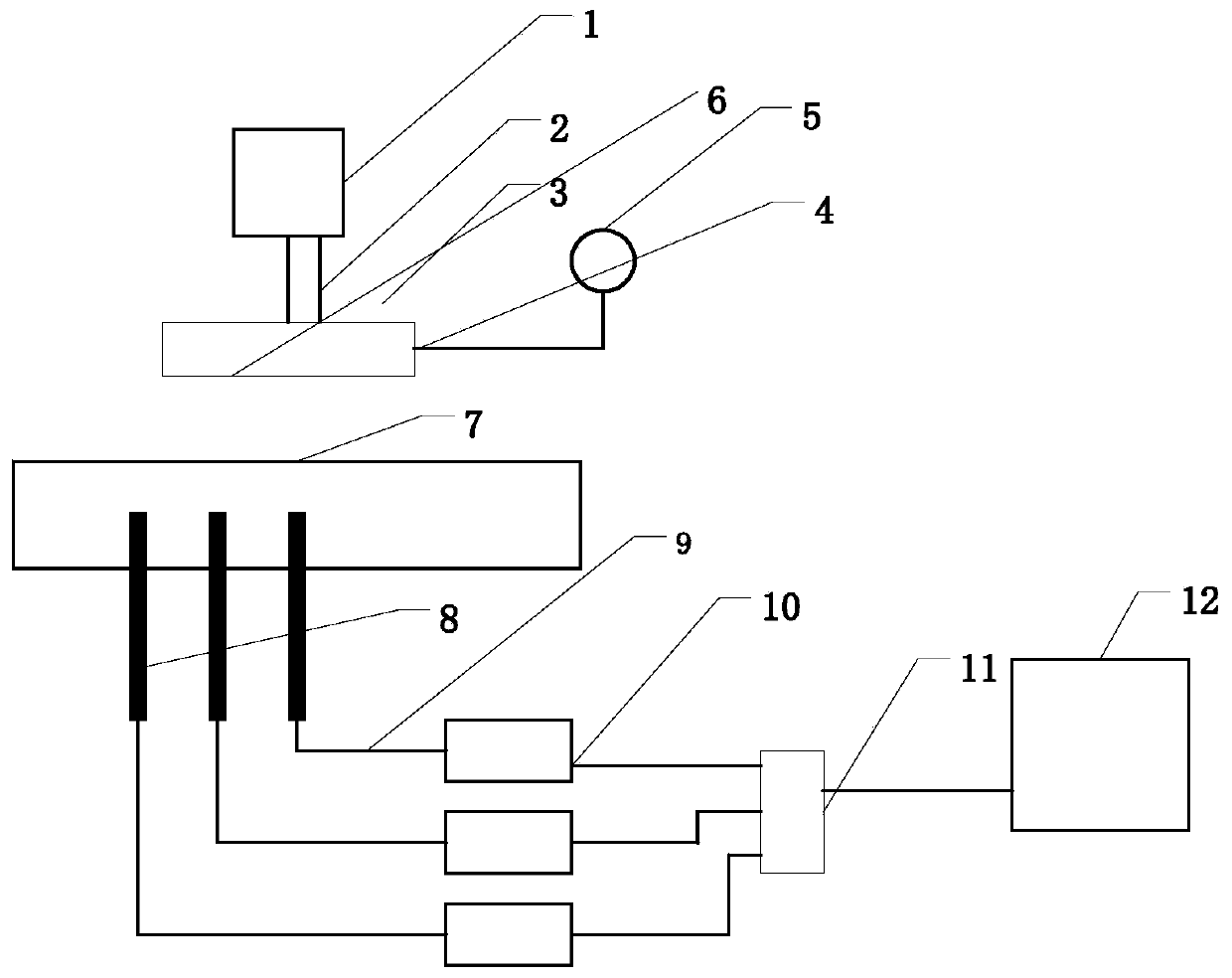

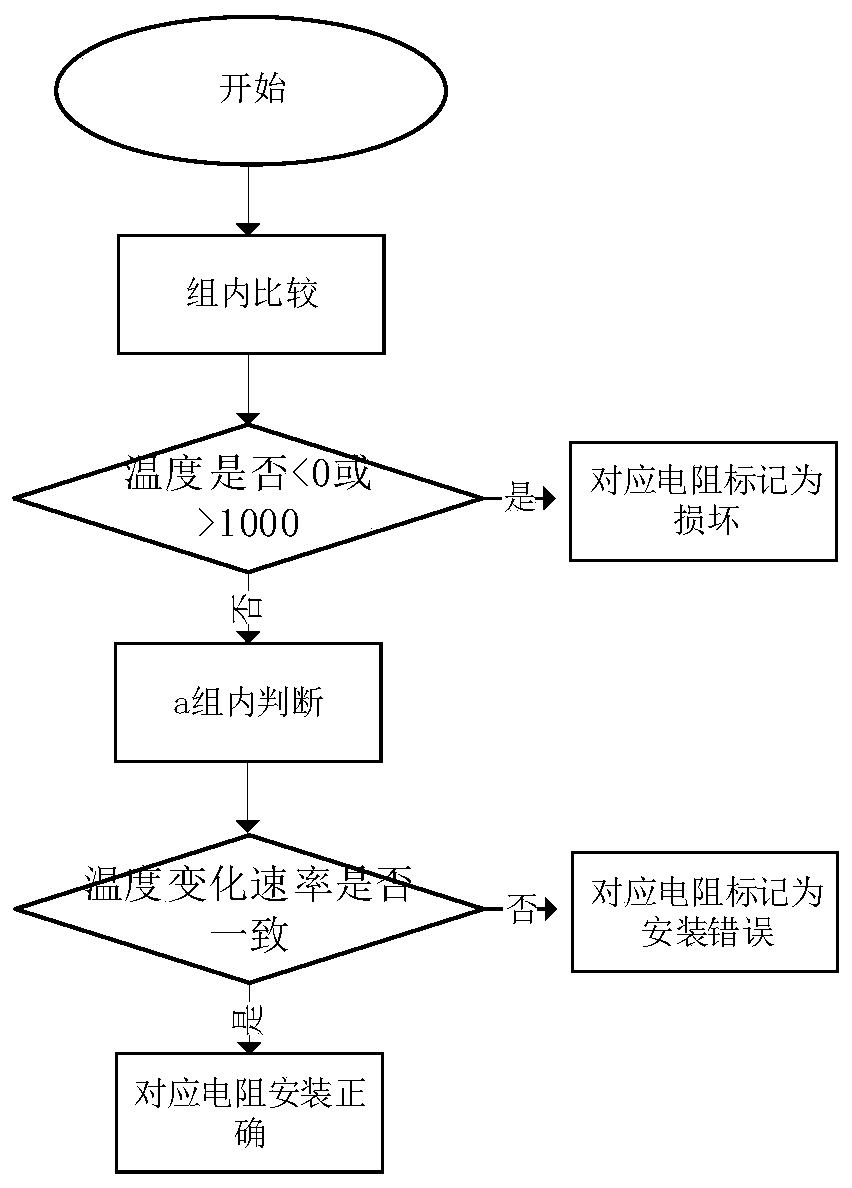

[0041]1. The idea of the present invention is to design a local heater based on the precise temperature control of far-infrared heating technology to ensure that each test is uniform heating of continuous casting steel plates; use a computer, a high-precision temperature compensator, and a temperature data acquisition card , The temperature acquisition system composed of thermal resistance; collect the temperature of the continuous casting steel plate, and judge the installation quality of the thermal resistance through the established judgment algorithm. The method for judging the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com