Casting method for aluminum alloy engine shell

An engine casing and aluminum alloy technology, applied in the field of aluminum alloy casting, can solve the problems of inapplicability, high price, high labor intensity, etc., and achieve the effects of saving production costs, improving strength, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

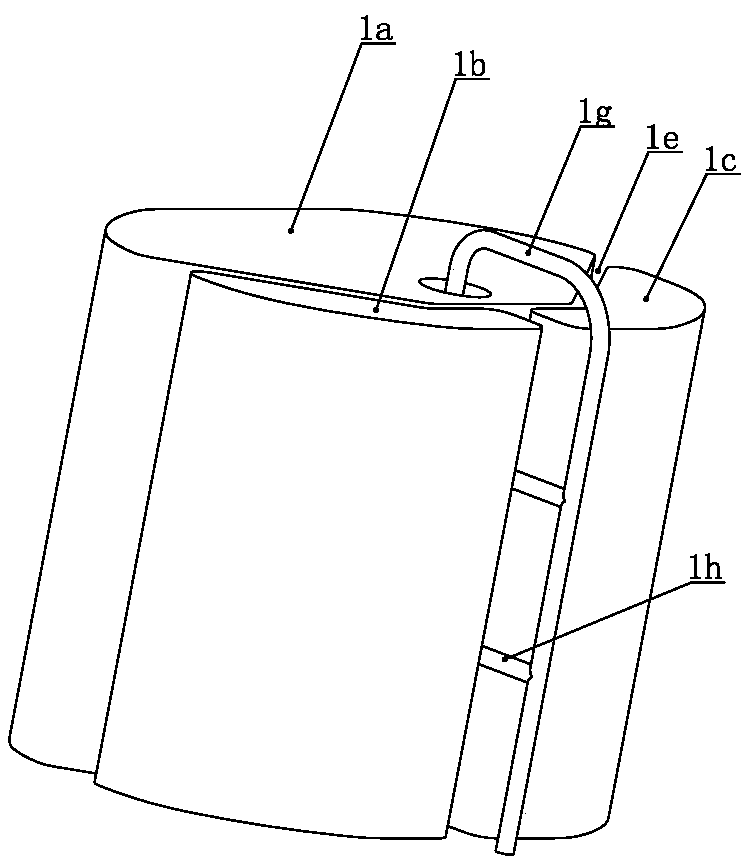

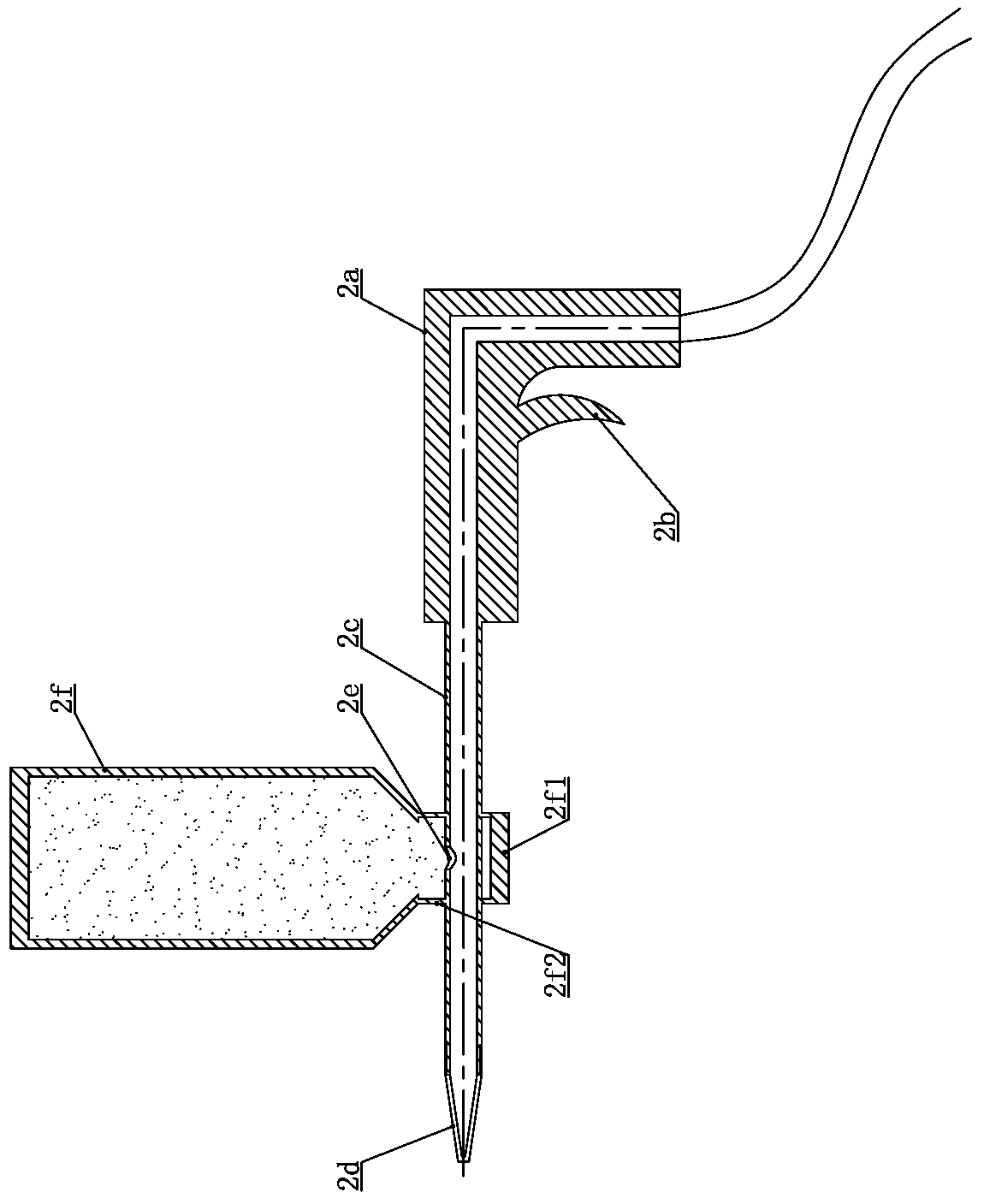

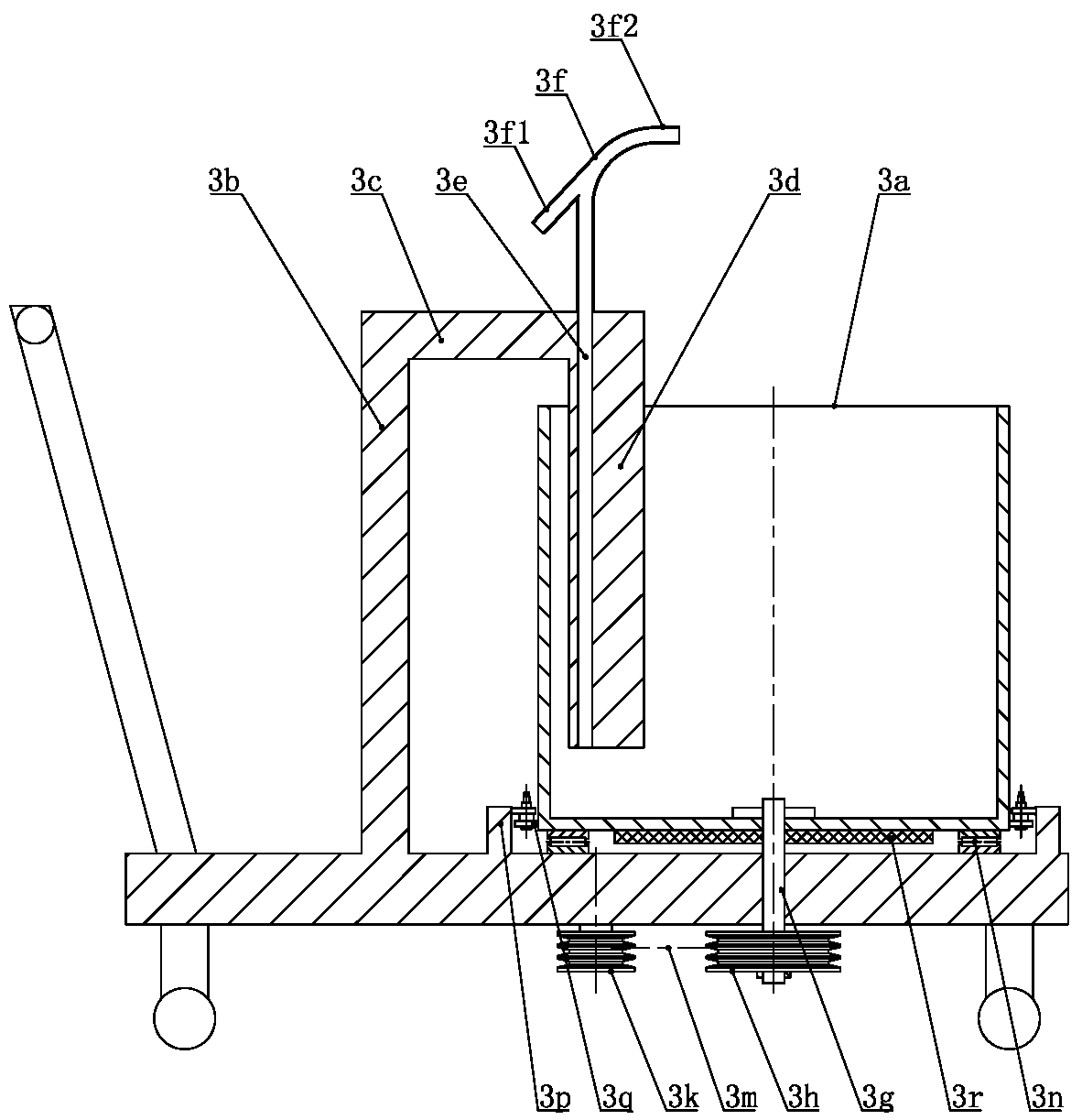

[0035] Such as Figure 1 to Figure 14 As shown, the casting method of the aluminum alloy engine casing of the present invention comprises the following steps in turn: (1) the copper tube is made into the same shape as the oil passage 7d on the engine casing 7 through a mold, and the sand filling tool for the curved hole is used to fill the copper tube into the copper tube. The cavity is filled with coated sand, and then the port of the copper tube is closed; (2) the core 1 is made with the same shape as the inner cavity of the engine casing 7; (3) the copper tube is combined with the core 1 and fixed, as figure 1 Shown; (4) Dip the core 1 into the slurry dipping machine and dip the refractory coating, after taking it out, spray the refractory sand on the surface of the core 1 through the sand pouring machine, then dip the slurry, then pour the sand, repeat several layers to get the inner mold shell, The inner mold shell is dewaxed after being air-dried, and then baked at high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com