Multifunctional combined low dew point dryer

A combined, low dew point technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of large floor space, large regeneration gas consumption, large regeneration gas loss, etc., and reduce equipment energy consumption. , The effect of small regeneration gas consumption and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

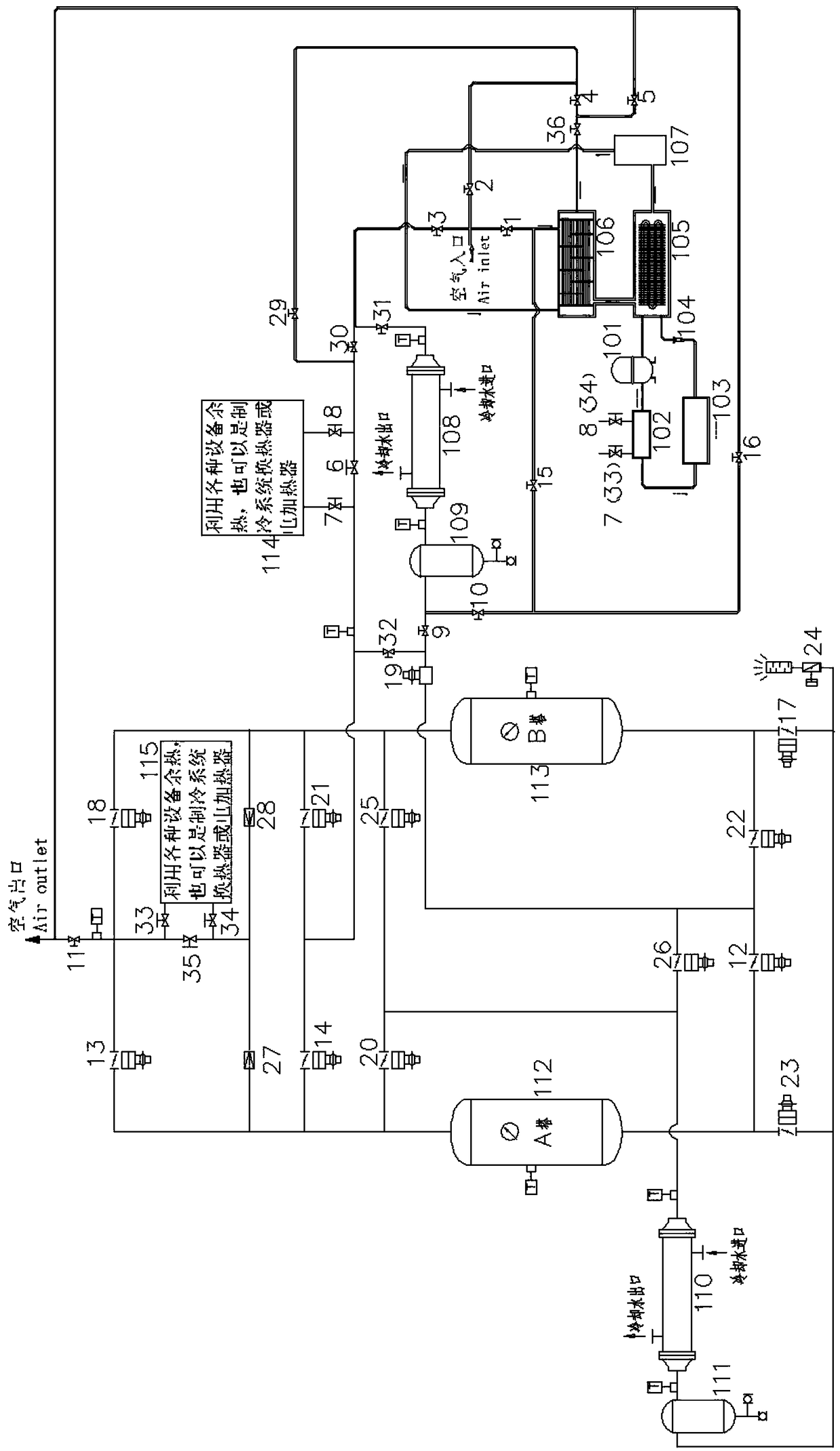

[0036] The present invention will be further described below through specific embodiments and accompanying drawings.

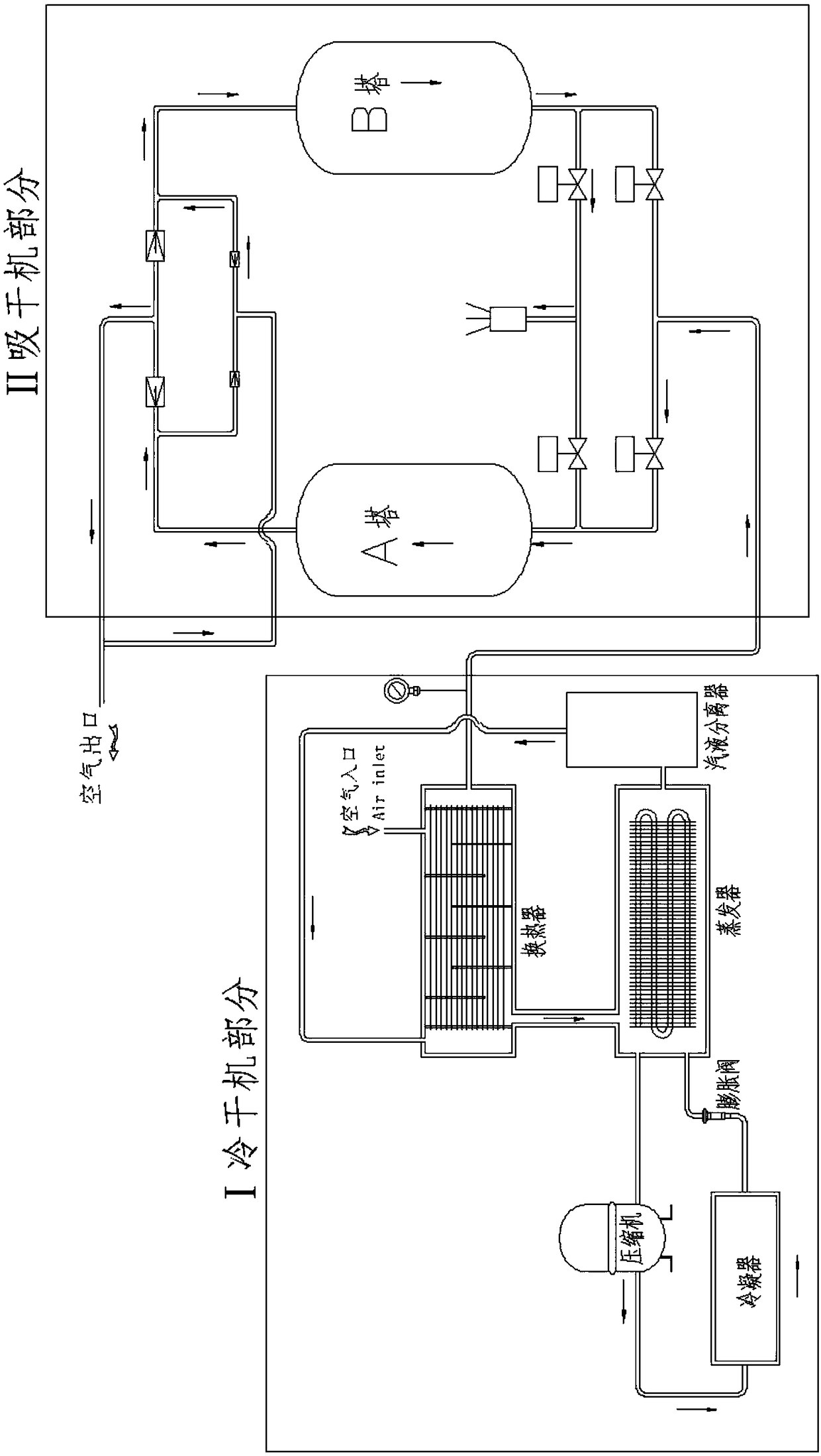

[0037] Such as figure 2 As shown, a multifunctional combined low dew point dryer mainly includes a cold dryer part and a suction dryer part. Through the switch coordination of each valve and reasonable pipeline connection, it has a variety of working modes to realize the multi-purpose function of the equipment, as follows:

[0038] Working method one: combine image 3 As shown, when the air inlet temperature of the equipment is 80℃~140℃, or the air inlet temperature is ≥140℃, the air outlet temperature of the equipment is required to be ≤45℃, and it is used as a "rear cooler", including the air inlet to the valve 3 in sequence according to the air flow direction , valve 31, first aftercooler 108, first separator 109, valve 10 and valve 16 to air outlet.

[0039] Working method two: combine Figure 4 As shown, when the air inlet temperature of the equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com