Sliding track mechanism

A technology of slide rails and pulleys, applied in the field of slide rail mechanisms, which can solve problems such as the inability to adjust the upper and lower positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

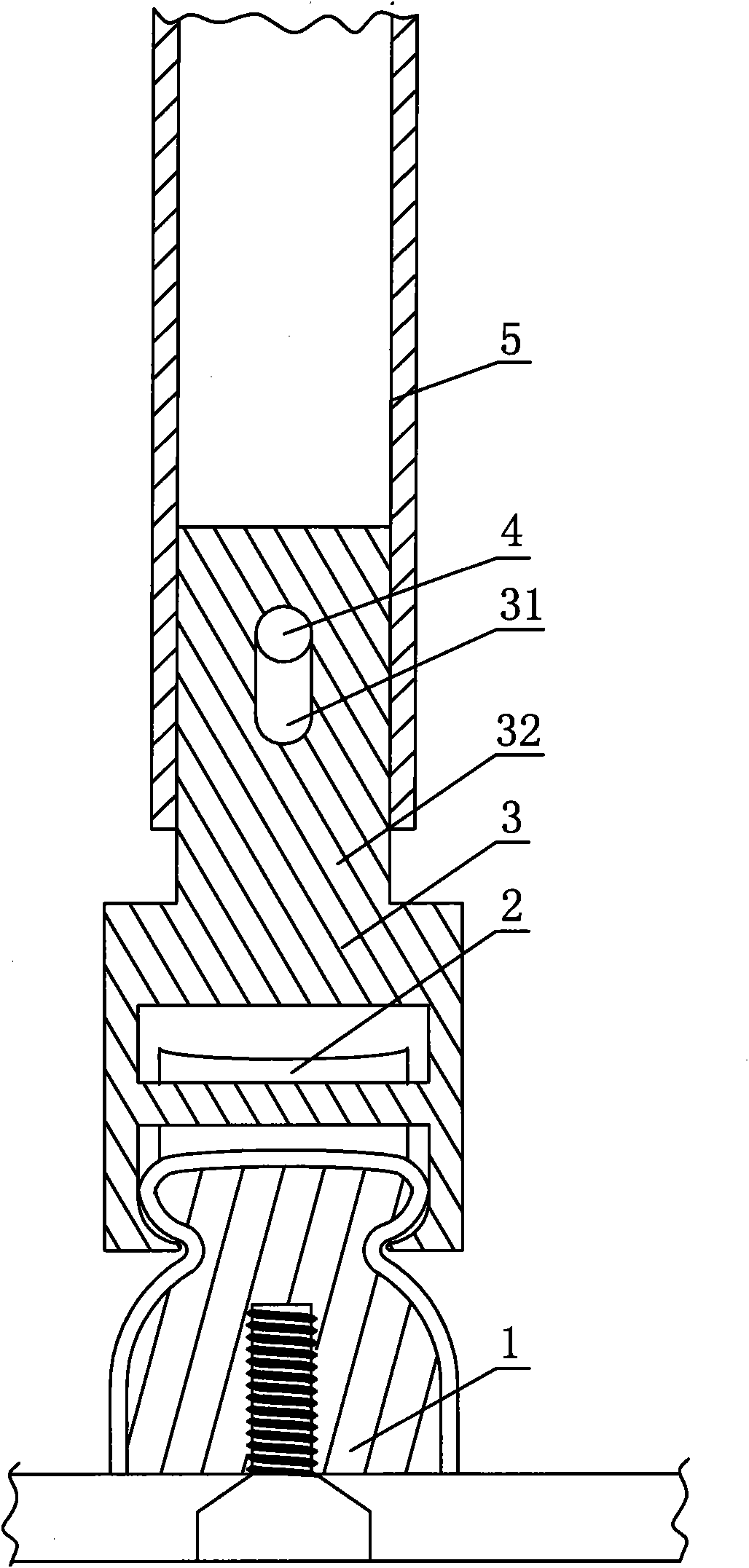

[0011] Such as figure 1 As shown, it is a preferred embodiment of a slide mechanism of the present invention, including a fixed track 1 and a pulley 2 sliding on the track, the pulley is arranged on a pulley member 3, and the pulley member is installed on a pulley bracket 5, wherein the The pulley bracket 5 is a hollow tube, and the mounting arm 32 at the pulley part rear portion is arranged in the hollow tube. The mounting arm has a through groove 31, and the pulley positioning core 4 runs through the hollow tube and the through groove to fix the pulley part on the hollow tube. The longitudinal length of the through-slot is greater than the outer diameter of the positioning core, and the pulley is adjusted up and down along the positioning core through the through-slot. The pulley bracket is a flat hollow tube, and the pulley pieces are sheet-shaped to cooperate with the pulley bracket.

[0012] Such as figure 2 As shown, it is another embodiment of a slide rail mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com