A kind of internal fixation system and using method thereof

A fixation system and bone plate technology, applied in the field of internal fixation systems, can solve problems such as inability to achieve fixation effects, failure of fixation, and inability to practically apply the internal fixation system, reducing hospitalization rates and length of stay, avoiding stress shielding effects, and being reliable. The effect of internal fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

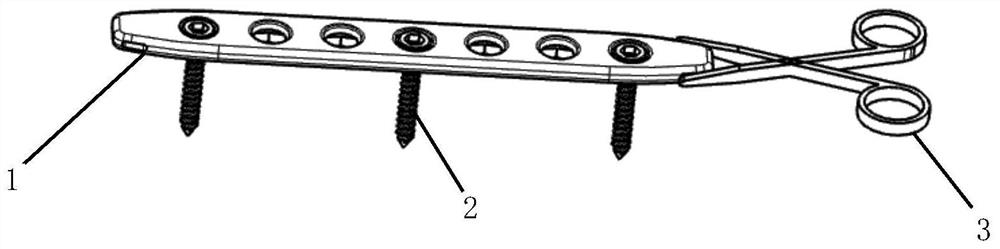

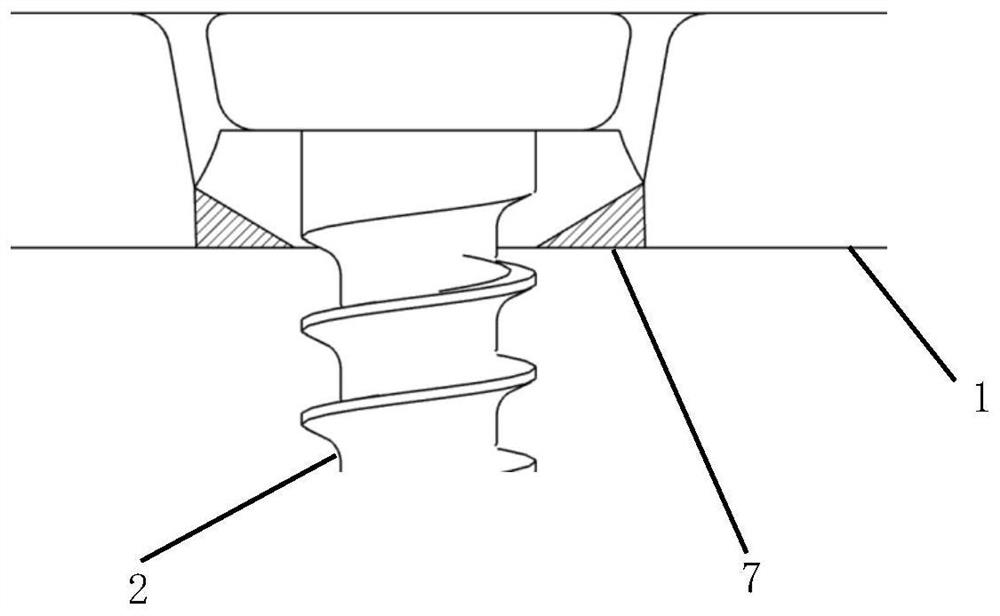

[0042] In this embodiment, magnesium-calcium alloy bone screws combined with titanium alloy bone plates, and an internal fixation removal forceps are used for minimally invasive treatment of limb bone fractures with low load-bearing strength. The bone screw is a conventional cortical bone screw processed from a magnesium-calcium alloy extruded rod with a Ca mass fraction of 3%. The total content of impurity elements Al, Cu, Fe, Mn, Ni and Si in the magnesium-calcium alloy is less than 0.01%. The ingot is obtained through a secondary extrusion process to obtain a 6mm diameter rod. The extrusion ratios of the two extrusions are 3.8 and 122.7 respectively, and the extrusion temperature is 280-380 degrees. The tensile strength of the bar is 310MPa, the yield strength is 253MPa, the elongation after fracture is 11%, the reduction of area is 13%, and the microhardness is 65.3Hv. The magnesium-calcium alloy rod is machined into a bone screw, and a layer of calcium-phosphorus biocera...

Embodiment 2

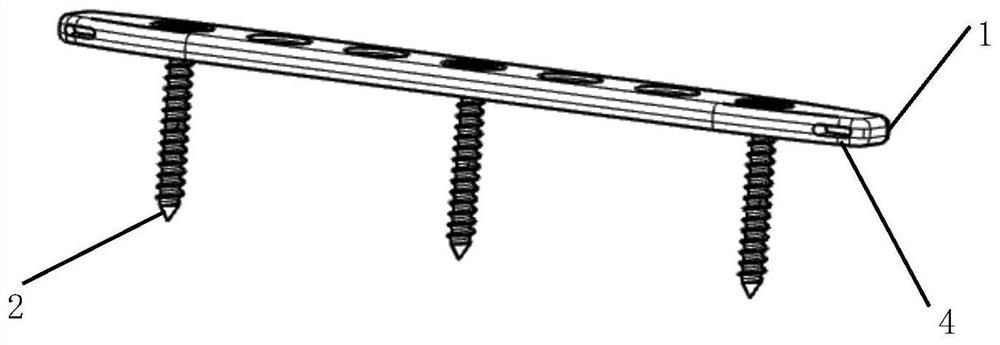

[0057] In this embodiment, the internal fixation system needs to be used with a guide to perform minimally invasive treatment of limb bone fractures with low load-bearing strength, and the bone screws are magnesium-zinc-calcium screws.

[0058] The bone screw can be a locking screw or a non-locking screw, which is not limited here. The bone screw in this embodiment is made of a forged magnesium-zinc-calcium alloy bar with a mass fraction of Zn of 3% and a mass fraction of Ca of 0.5%. The total content of impurity elements Al, Cu, Fe, Mn, Ni and Si in the magnesium-zinc-calcium alloy is less than 0.01%. The ingot is obtained by a hot swaging process to obtain a rod with a diameter of 6mm, the swaging temperature is 200-350 degrees, and the total deformation rate of the section is 96%. The obtained rod has a tensile strength of 385MPa, a yield strength of 320MPa, an elongation after fracture of 12%, a reduction of area of 15%, and a microhardness of 71.2Hv.

[0059] The magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com