Preparation technology for improving quality of large-tank fermented soy sauce

A preparation process and soy sauce technology are applied in the field of preparation for improving the quality of fermented soy sauce in large tanks, and can solve problems such as affecting protease activity, taste of soy sauce, poor aroma, and thin soy sauce flavor, so as to avoid competition for nutrients and avoid conversion of raw materials. rate, the effect of thin soy sauce flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

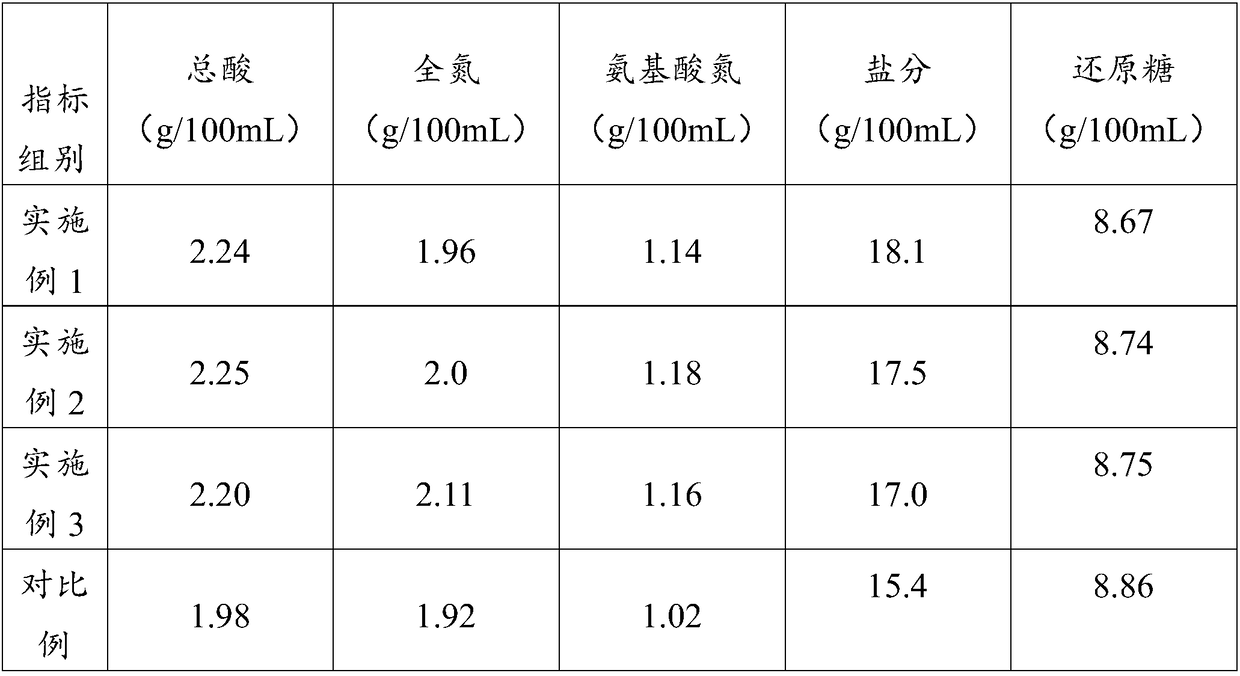

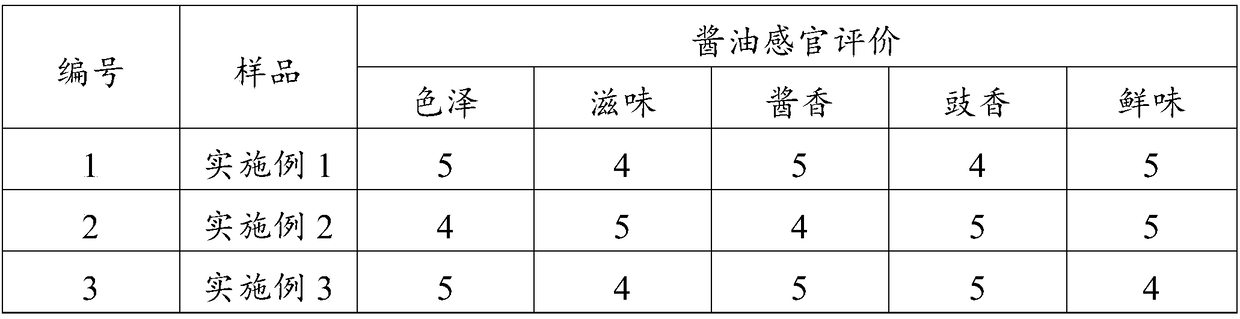

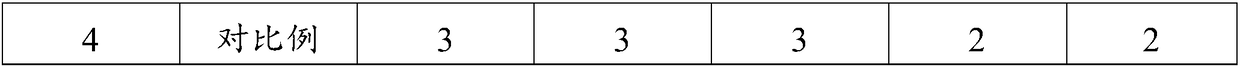

Embodiment 1

[0027] An embodiment of the preparation process for improving the quality of fermented soy sauce in a large tank according to the present invention. The preparation process in this embodiment includes the following steps:

[0028] (1) Using soybean meal and wheat flour as raw materials to prepare the koji material according to the conventional soy sauce koji preparation method, then the koji material and the brine are made into koji material in a weight ratio: brine=1:0.8, and the mixture is kept at 40~52℃ for fermentation. Soy sauce stock solution made in heaven;

[0029] (2). By constructing a high-throughput sequencing library for the soy sauce stock solution obtained in step (1), and carrying out bioinformatics analysis of the experimental results, it can be known that the dominant bacteria in the soy sauce stock solution are Weissella ( weissella), Staphylococcus (staphylococcus) and salt-tolerant Pediococcus (pediococcus), accounting for 19%, 8% and 58%, respectively. The soy...

Embodiment 2

[0033] An embodiment of the preparation process for improving the quality of fermented soy sauce in a large tank according to the present invention, the preparation process in this embodiment includes the following steps:

[0034] (1) Use soybean meal and wheat flour as raw materials to prepare koji material according to the conventional soy sauce koji preparation method, and then mix the koji material and salt water in a weight ratio: salt water=1:0.8 mix, and heat and ferment at 40~52℃ for 30 Soy sauce stock solution made in heaven;

[0035] (2). By constructing a high-throughput sequencing library for the soy sauce stock solution obtained in step (1), and performing bioinformatics analysis on the experimental results, it can be known that the dominant bacteria in the soy sauce stock solution are Weissella ( weissella), staphylococcus and salt-tolerant Pediococcus (pediococcus), which accounted for 20%, 74.5% and 0.5%, respectively. The soy sauce stock solution was kept and reser...

Embodiment 3

[0039] An embodiment of the preparation process for improving the quality of fermented soy sauce in a large tank according to the present invention, the preparation process in this embodiment includes the following steps:

[0040] (1) Using soybean meal and wheat flour as raw materials to prepare the koji material according to the conventional soy sauce koji preparation method, then the koji material and the brine are made into the koji material in a weight ratio: brine=1:0.8, and the mixture is kept at 40~52℃ for fermentation. Soy sauce stock solution made in heaven;

[0041] (2). By constructing a high-throughput sequencing library for the soy sauce stock solution obtained in step (1), and performing bioinformatics analysis on the experimental results, it can be known that the dominant bacteria in the soy sauce stock solution are Weissella ( weissella), staphylococcus and salt-tolerant Pediococcus (pediococcus) accounted for 12%, 85.5% and 0.5% respectively. The soy sauce stock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com