Bimetal-layer annular-interdigital-electrode flip-chip LED chip and manufacturing method thereof

A technology of LED chips and interdigitated electrodes, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of uneven distribution of chip current, current aggregation, etc., and achieve the effects of free configuration, improved yield rate, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the drawings.

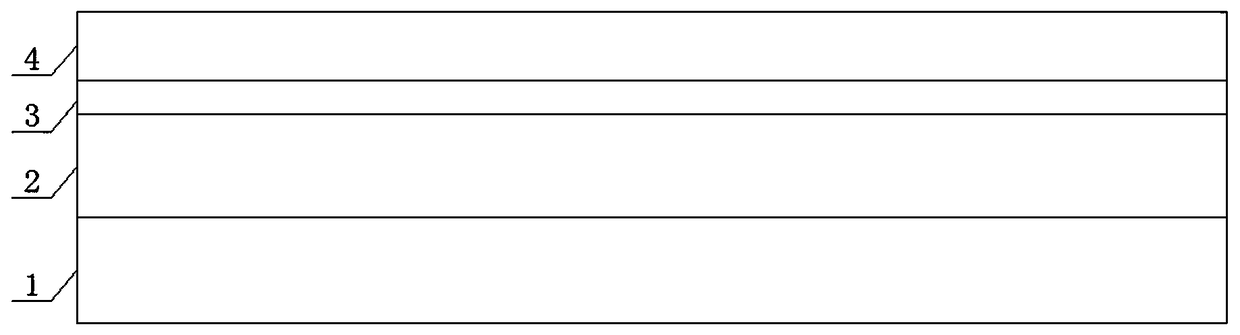

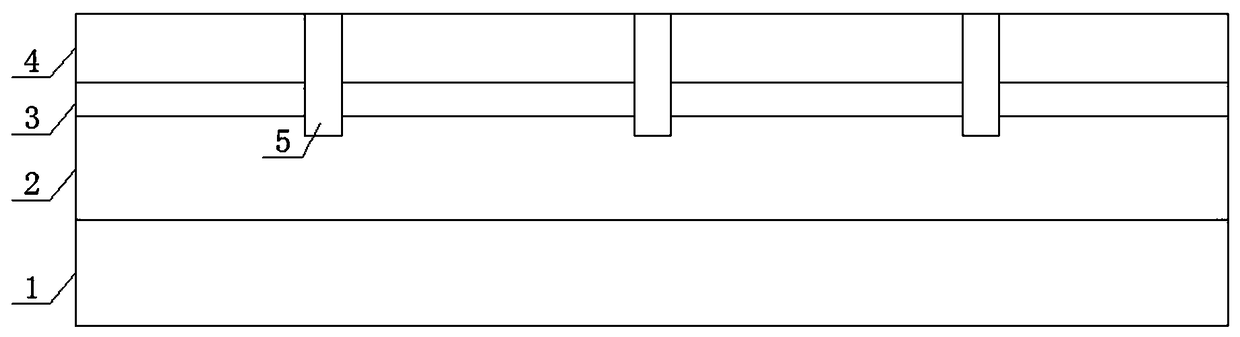

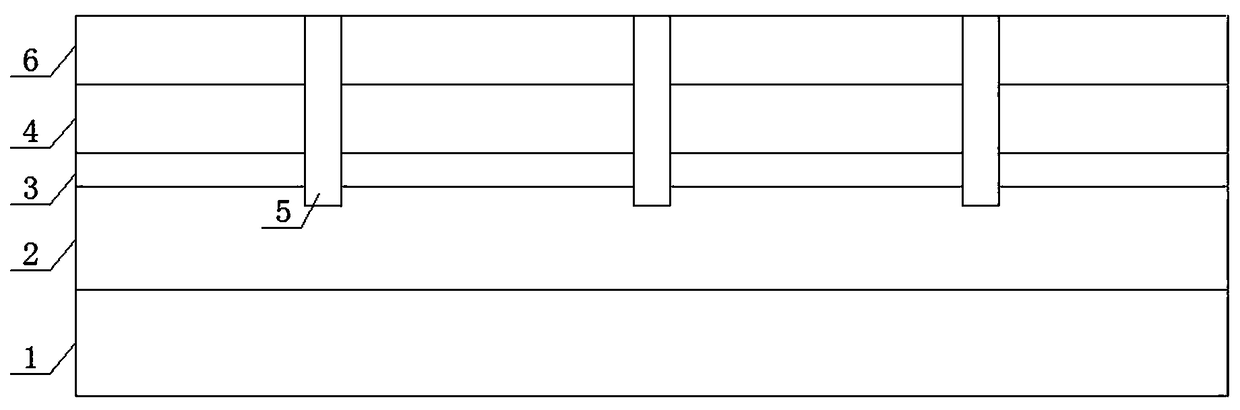

[0036] Such as Figure 5 to Figure 8 As shown, a double-metal layer ring-shaped interdigital electrode flip-chip LED chip includes a substrate 1, an n-type semiconductor layer 2, a light-emitting layer 3, and a p-type semiconductor layer 4 from bottom to top, on the p-type semiconductor layer 4 A current spreading layer 6 electrically connected to the p-type semiconductor layer 4 is provided, a first insulating isolation layer 7 insulated and connected to the current spreading layer 6 is provided on the current spreading layer 6, and the first insulating isolation layer 7 is divided into A plurality of n-pole annular belts distributed concentrically and equidistantly and a plurality of p-pole annular belts distributed concentrically and equidistantly, the n-pole annular belts and the p-pole annular belts are alternately arranged to form an annular interdigital structure;

[0037] A plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com