Method for measuring nitrogen in carbon series heating agent

A measurement method and technology of heating agent, which is applied in the field of nitrogen measurement in carbon-based heating agents, can solve problems such as inapplicable melting method, and achieve significant economic benefits, reliable data support, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

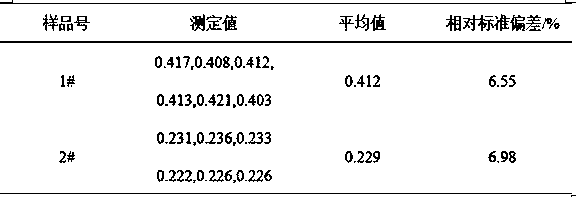

Embodiment 1

[0021] The mensuration of nitrogen content in the carbon series warming agent, its concrete steps are as follows:

[0022] a. Sample preparation: take a sample with a particle size not greater than 0.2mm, dry it at 105°C, put it in a desiccator, and wait for the test;

[0023] b. Blank experiment: choose a special graphite crucible and tin capsule for gas analysis to conduct a systematic blank experiment, repeat 5 to 7 times, record the three measurement results that are relatively stable and consistent, and calculate the average value and input it into the inert gas melting thermal conductivity detector as a blank value , The inert gas melting thermal conductivity detector automatically deducts the blank value when measuring the sample.

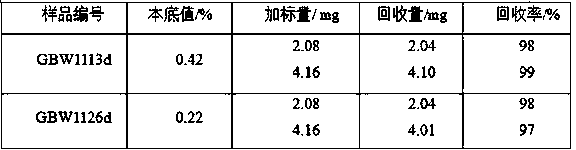

[0024] c. Calibration of the instrument: Weigh 0.01g GBW1113d and GBW1126d coal standard samples to establish the working curve of nitrogen, and choose GBW1113d as the drift correction standard sample to detect the accuracy of the method.

...

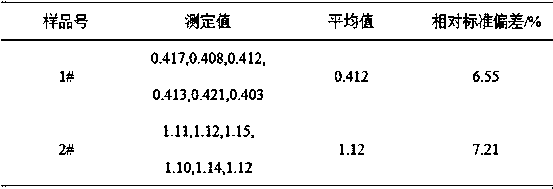

Embodiment 2

[0033] The determination of the nitrogen content in the carbon-based temperature raising agent, the specific steps are as follows:

[0034] a. Sample preparation: take a sample with a particle size of 0.2mm, dry the prepared sample in an oven at 105°C, put it in a desiccator to cool, and wait for testing;

[0035] b. Blank experiment: choose a special graphite crucible and tin capsule for gas analysis to conduct a systematic blank experiment, repeat it enough times, record the three measurement results that are relatively stable and consistent, calculate the average value and input it into the inert gas melting thermal conductivity detector as a blank value, and measure The inert gas melting thermal conductivity detector automatically deducts the blank value when the sample is taken.

[0036] c. Calibration of the instrument: Weigh 0.02g GBW1113d and GBW(E)110042GBW(E)110039 coal standard samples to establish the working curve of nitrogen, and choose GBW(E)110039 as the accura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com