Construction method of bearing platform and basement floor in deep soft soil area

A basement floor and construction method technology, applied in the direction of excavation, artificial island, sheet pile wall, etc., can solve the problems of increased cost, inability to pull out, slow construction speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

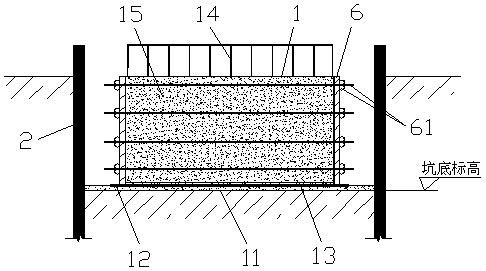

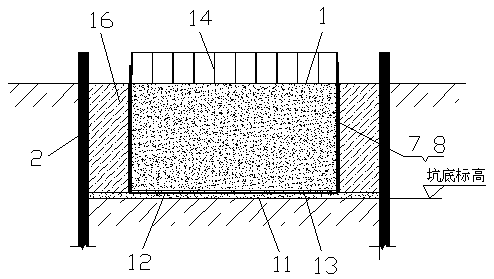

[0021] Example Figure 1 to Figure 4 As shown, the construction method of the cap platform and the basement floor in the deep soft soil region of the present invention comprises the following steps:

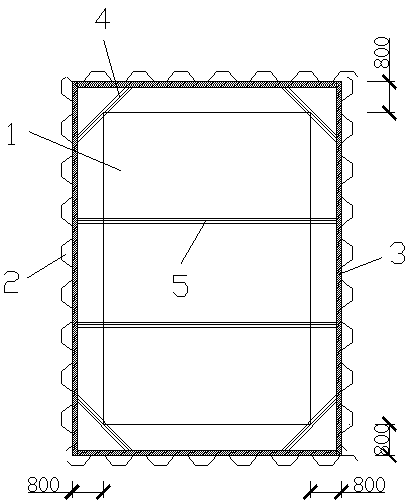

[0022] Step 1. Within the scope of the divided construction section, measure and set out the line according to the construction drawing of the cap, determine the position of the sideline of the cap 1, and construct the steel sheet pile 2 at a certain distance outside the sideline of the cap 1;

[0023] Step 2, according to the depth of the foundation pit, set the waist beam 3 along the steel sheet pile 2 through calculation, set the corner braces 4 at the corners of the waist beam 3, and set the opposite brace 5 between the waist beams 3 in the length direction;

[0024] Step 3: Excavate the earthwork of the cap 1 to the elevation of the bottom of the cap 1, and pour the cap cushion 11 at the bottom of the cap 1;

[0025] Step 4: Remove the corner brace 4, the opposite brace 5 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com