Filter capsule permeation resistance waterborne coating for tipping paper and preparation method thereof

A technology of water-based paint and tipping paper, which is applied in paper coating, papermaking, coating, etc., can solve the problems of process complexity, inability to take into account air permeability, complex process, etc., and achieve simple production process, low VOC residue, good The effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

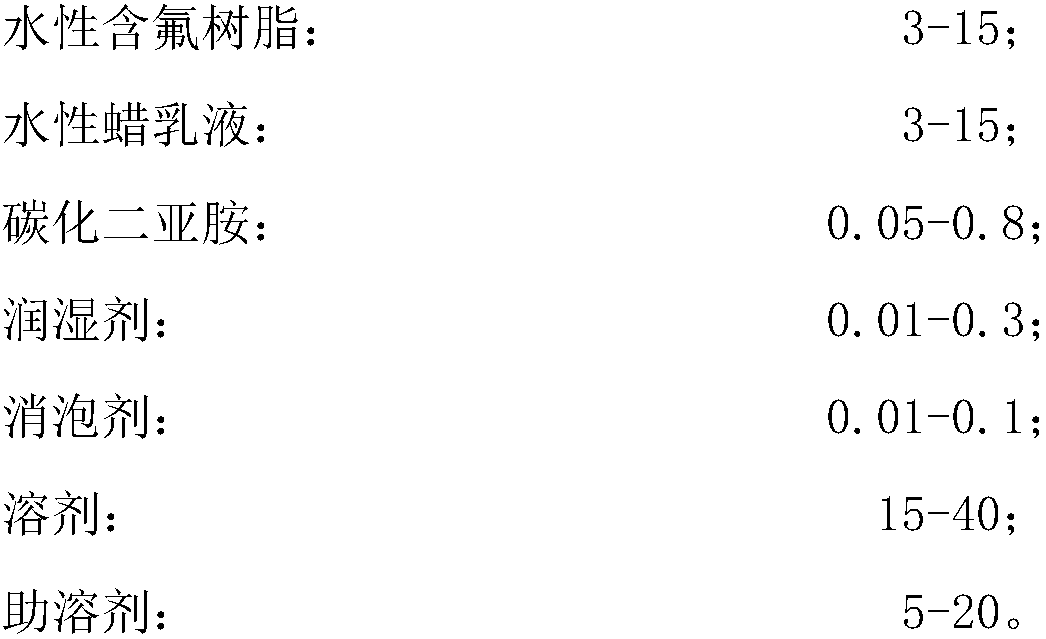

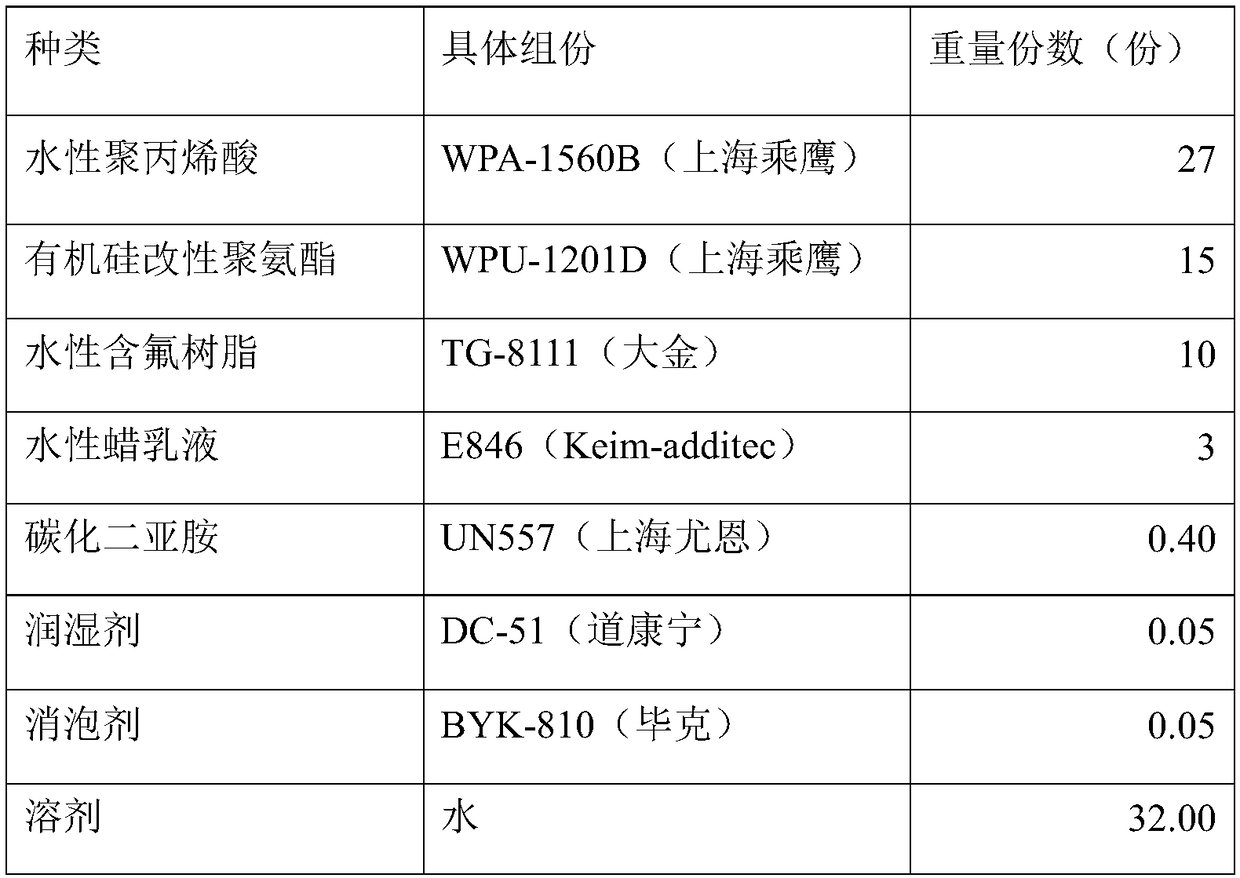

[0032] This embodiment provides an anti-seepage water-based coating for tipping paper, which is made of the following components and contents as raw materials:

[0033]

[0034]

[0035] The emulsion surface tension of the water-based fluorine-containing resin is below 28.

[0036] The water-based wax emulsion is a high-density polyethylene water-based wax emulsion.

[0037] The decomposition temperature of the carbodiimide is ≥130°C.

[0038] The preparation method is as follows:

[0039] Step A. Mix the above-mentioned water-based polyacrylic acid, silicone-modified polyurethane, water-based fluorine-containing resin, and water-based wax emulsion in a reaction kettle, heat up to 40-50°C, and stir at a low speed for 5-10 minutes;

[0040] Step B, adding the above-mentioned solvent while stirring, and stirring at a low speed for 5-10 minutes;

[0041] Step C, add the above co-solvent while stirring, and stir at a medium speed for 5-10 minutes;

[0042] Step D, add th...

Embodiment 2

[0047] This embodiment provides an anti-seepage water-based coating for tipping paper, which is made of the following components and contents as raw materials:

[0048]

[0049]

[0050] The preparation method is the same as in Example 1.

Embodiment 3-5

[0052] Embodiment 3-5 provides a kind of anti-seepage water coating for tipping paper, the component raw material that this coating adopts is identical with embodiment 1, and the parts by weight of each component are as follows:

[0053] type

[0054] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com