Method for preparing steel additive by taking waste steel as raw material

A technology for steel additives and raw materials, applied in the direction of improving process efficiency, can solve problems such as incomplete reduction, change in steel properties, poor steel toughness, etc., and achieve the effect of reducing impurity content, improving strength, and facilitating forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

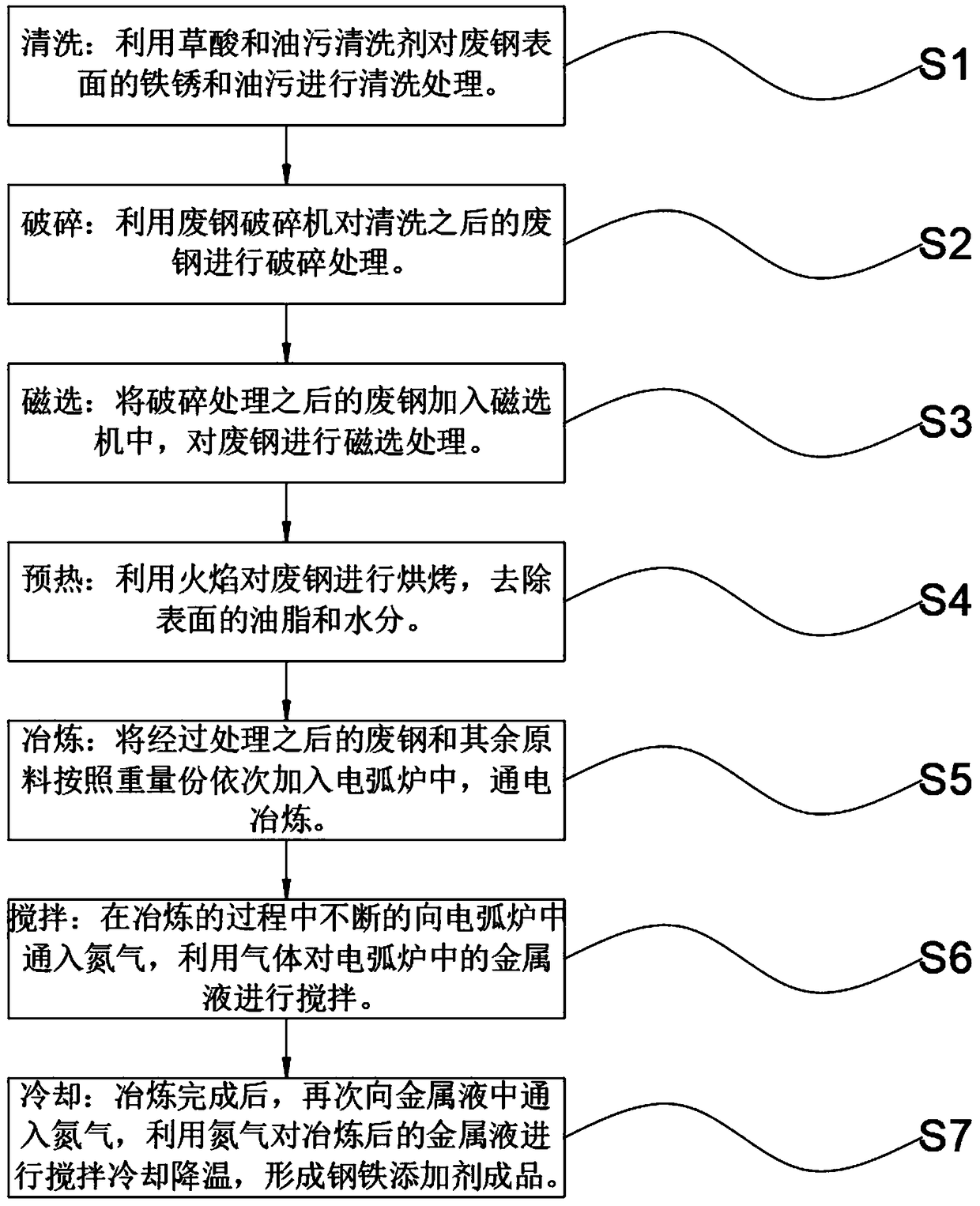

[0026] Embodiment 1: as figure 1 As shown, the present invention provides a technical solution, a steel additive, and the steel additive is made of the following raw materials in parts by weight: 95 parts of scrap steel, 15 parts of iron ore, 17 parts of metallic aluminum, 12 parts of graphite, and 13 parts of ferrosilicon powder , 25 parts of aluminum oxide, 7 parts of manganese silicide, 3 parts of bismuth and 5 parts of antimony trioxide.

[0027] A method for preparing iron and steel additives from scrap steel, comprising the steps of:

[0028] S1. Cleaning: use oxalic acid and oil cleaning agent to clean the rust and oil on the surface of scrap steel;

[0029] S2. Crushing: use the scrap steel crusher to crush the cleaned scrap steel;

[0030] S3. Magnetic separation: add the crushed steel scrap into the magnetic separator, and perform magnetic separation on the steel scrap;

[0031] S4. Preheating: use flame to bake the scrap steel to remove the grease and moisture on...

Embodiment 2

[0042] Embodiment 2: as figure 1 As shown, the present invention provides a technical solution, a steel additive, and the steel additive is made of the following raw materials in parts by weight: 90 parts of scrap steel, 10 parts of iron ore, 15 parts of metallic aluminum, 10 parts of graphite, and 10 parts of ferrosilicon powder , 20 parts of aluminum oxide, 5 parts of manganese silicide, 2 parts of bismuth and 3 parts of antimony trioxide.

[0043] A method for preparing iron and steel additives from scrap steel, comprising the steps of:

[0044] S1. Cleaning: use oxalic acid and oil cleaning agent to clean the rust and oil on the surface of scrap steel;

[0045] S2. Crushing: use the scrap steel crusher to crush the cleaned scrap steel;

[0046] S3. Magnetic separation: add the crushed steel scrap into the magnetic separator, and perform magnetic separation on the steel scrap;

[0047] S4. Preheating: use flame to bake the scrap steel to remove the grease and moisture on...

Embodiment 3

[0058] Embodiment 3: as figure 1 As shown, the present invention provides a technical solution, a steel additive, and the steel additive is made of the following raw materials in parts by weight: 100 parts of scrap steel, 20 parts of iron ore, 20 parts of metallic aluminum, 15 parts of graphite, and 15 parts of ferrosilicon powder , 30 parts of aluminum oxide, 10 parts of manganese silicide, 5 parts of bismuth and 7 parts of antimony trioxide.

[0059] A method for preparing iron and steel additives from scrap steel, comprising the steps of:

[0060] S1. Cleaning: use oxalic acid and oil cleaning agent to clean the rust and oil on the surface of scrap steel;

[0061] S2. Crushing: use the scrap steel crusher to crush the cleaned scrap steel;

[0062] S3. Magnetic separation: add the crushed steel scrap into the magnetic separator, and perform magnetic separation on the steel scrap;

[0063] S4. Preheating: use flame to bake the scrap steel to remove the grease and moisture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com